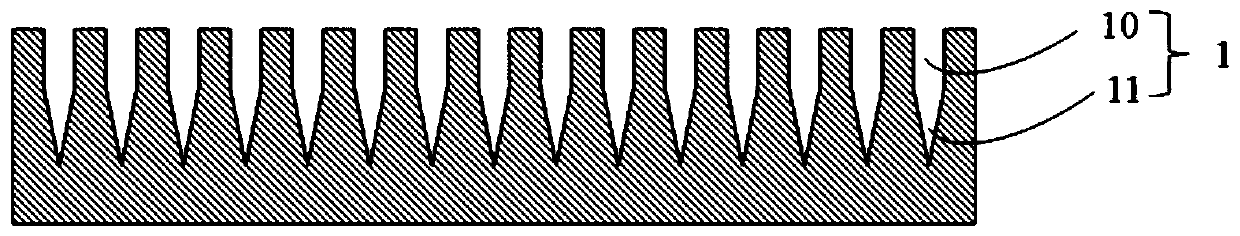

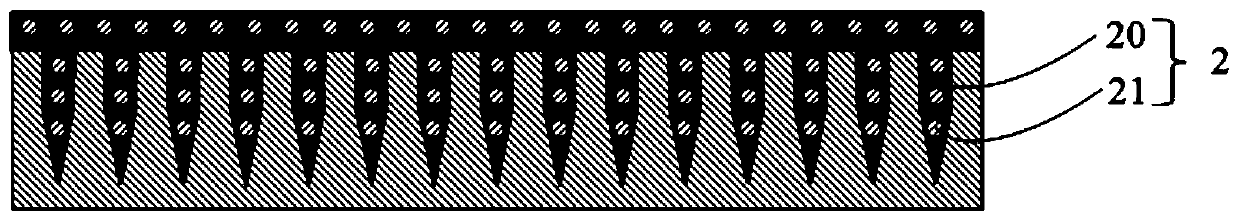

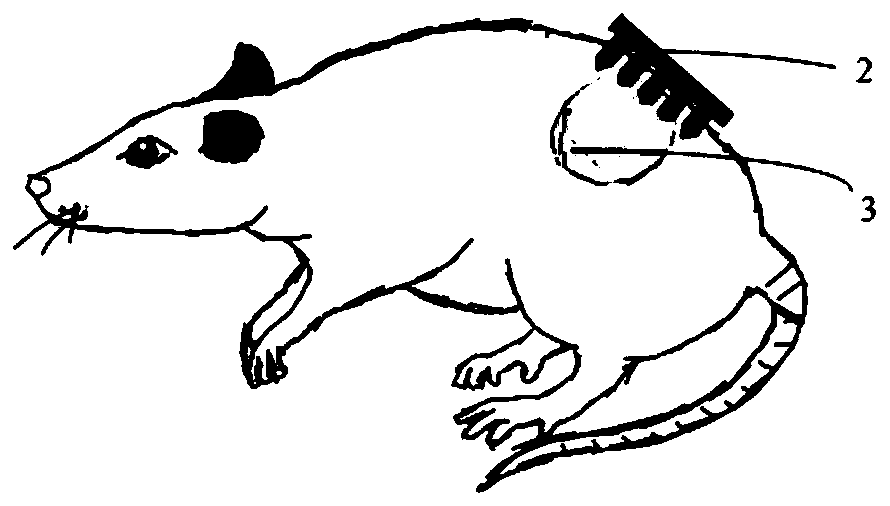

Photoelectric microneedle, as well as preparation method and application thereof

A photoelectric effect and photoelectric technology, applied in microneedling, phototherapy, needles, etc., can solve the problems of unclean lesion removal, large skin damage area, easy recurrence, etc., achieving good application prospects, efficient killing, and broad development space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1 Preparation of photoelectric microneedles

[0064] A method for preparing a photoelectric microneedle, specifically comprising the following steps:

[0065] S1. Mix zinc oxide and graphite phase carbon nitride at a mass ratio of 0.21:1 to obtain nanoparticles with photoelectric effect, and prepare nanoparticles with a concentration of 250 μg / mL;

[0066] S2. Mix the nanoparticles obtained in step S1 with hyaluronic acid in a ratio of 1:1, and stir to obtain a mixture;

[0067] S3. The mixture obtained in step S2 is injected into the microneedle array mold under the condition of a pressure of 5Mpa, and heated to 80°C at a speed of 5°C / min, and the heating time is 8h;

[0068] S4. After cooling and forming, the photoelectric microneedles are taken out from the microneedle array mold.

[0069] In step S1, the preparation method of nanoparticles with a concentration of 250 μg / mL is as follows: put 1 mg of nanoparticles into DMEM high-glucose medium containing...

Embodiment 2

[0072] Embodiment 2 Preparation of photoelectric microneedles

[0073] A method for preparing a photoelectric microneedle, specifically comprising the following steps:

[0074] S1. Mix zinc oxide and graphite phase carbon nitride at a mass ratio of 0.08:1 to obtain nanoparticles with photoelectric effect, and prepare nanoparticles with a concentration of 250 μg / mL;

[0075] S2. Mix the nanoparticles obtained in step S1 with polylactic acid in a ratio of 3:5, and stir to obtain a mixture;

[0076] S3. inject the mixture obtained in step S2 into the microneedle array mold under the condition of a pressure of 1Mpa, and heat to 60°C at a speed of 2°C / min for a heating time of 4h;

[0077] S4. After cooling and forming, the photoelectric microneedles are taken out from the microneedle array mold.

[0078] In step S1, the preparation method of nanoparticles with a concentration of 250 μg / mL is the same as that in Example 1.

[0079] The diameter of the photoelectric microneedle c...

Embodiment 3

[0080] Example 3 Preparation of photoelectric microneedles

[0081] A method for preparing a photoelectric microneedle, specifically comprising the following steps:

[0082] S1. Mix zinc oxide and graphite phase carbon nitride at a mass ratio of 0.42:1 to obtain nanoparticles with photoelectric effect, and prepare nanoparticles with a concentration of 250 μg / mL;

[0083] S2. Mix the nanoparticles obtained in step S1 with hyaluronic acid in a ratio of 8:5, and stir to obtain a mixture;

[0084] S3. The mixture obtained in step S2 is injected into the microneedle array mold under the condition of a pressure of 10Mpa, and heated to 90°C at a speed of 7°C / min for a heating time of 12h;

[0085] S4. After cooling and forming, the photoelectric microneedles are taken out from the microneedle array mold.

[0086] In step S1, the preparation method of nanoparticles with a concentration of 250 μg / mL is the same as that in Example 1.

[0087] The diameter of the photoelectric microne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com