Low-temperature shaped dried egg and processing method thereof

A processing method and technology for dried eggs, which are applied in the directions of food ingredients, food ingredients as coating agents, food ingredients as taste improvers, etc., can solve problems such as loss of nutritional value of eggs, and achieve the effects of shortening molding time and lowering molding temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

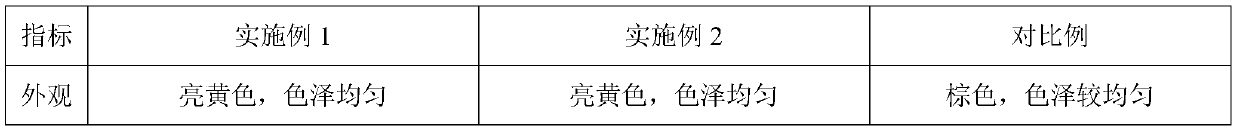

Embodiment 1

[0028] A dried egg and a processing method thereof, mainly comprising the following steps:

[0029] (1) Take the following raw materials by weight percentage: 45 parts of egg=egg white, 15 parts of egg=yolk, 6.5 parts of 56 ° Red Star Erguotou, 10 parts of corn germ oil (divided into 3.5 parts and 6.5 parts for step (7) , step (8)), 1.7 parts of salt, 0.5 parts of water-soluble ginger powder, 0.5 parts of pepper powder, 0.02 parts of ethyl maltol, 0.28 parts of vanillin, 4 parts of sodium bicarbonate, 8 parts of water, and 1.0 parts of yeast extract 1.5 parts of sugar, 1.5 parts of water-soluble chili powder, 1.5 parts of pepper powder, 1.5 parts of cumin powder, 1.5 parts of sesame, the sum of each raw material meets 100 parts;

[0030] (2) After mixing and stirring the egg white and egg yolk evenly, filter with a 60-mesh filter;

[0031] (3) Ingredients: Add salt, white wine, water-soluble ginger powder, ethyl maltol, vanillin, yeast extract, sugar, and water-soluble chili ...

Embodiment 2

[0038] A dried egg and a processing method thereof, mainly comprising the following steps:

[0039] (1) Take the following raw materials by weight percentage: 50 parts of egg whites, 10 parts of egg yolks, 6.5 parts of 56 ° Red Star Erguotou, 9 parts of corn germ oil (divided into 4 parts and 5 parts for step (6), step (7) )), 1.7 parts of salt, 0.5 parts of water-soluble ginger powder, 0.5 parts of pepper powder, 0.02 parts of ethyl maltol, 0.28 parts of vanillin, 4 parts of sodium bicarbonate, 8 parts of water, 1.0 part of water yeast extract, white sugar 1.5 parts, 2 parts of water-soluble chili powder, 2 parts of pepper powder, 1.5 parts of cumin powder, 1.5 parts of sesame, the sum of each raw material meets 100 parts;

[0040] (2) After mixing and stirring the egg white and egg yolk evenly, filter with a 60-mesh filter;

[0041] (3) Ingredients: Add salt, white wine, water-soluble ginger powder, ethyl maltol, vanillin, yeast extract, sugar, and water-soluble chili powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com