Tire X-ray defect detection method based on texture comparison

A technology of light detection and edge detection algorithm, applied in image data processing, instrumentation, calculation, etc., can solve problems such as puncture accidents and uneven tire force, and achieve the effect of solving misjudgment problems, reducing pressure, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe the present invention more specifically, the present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation examples.

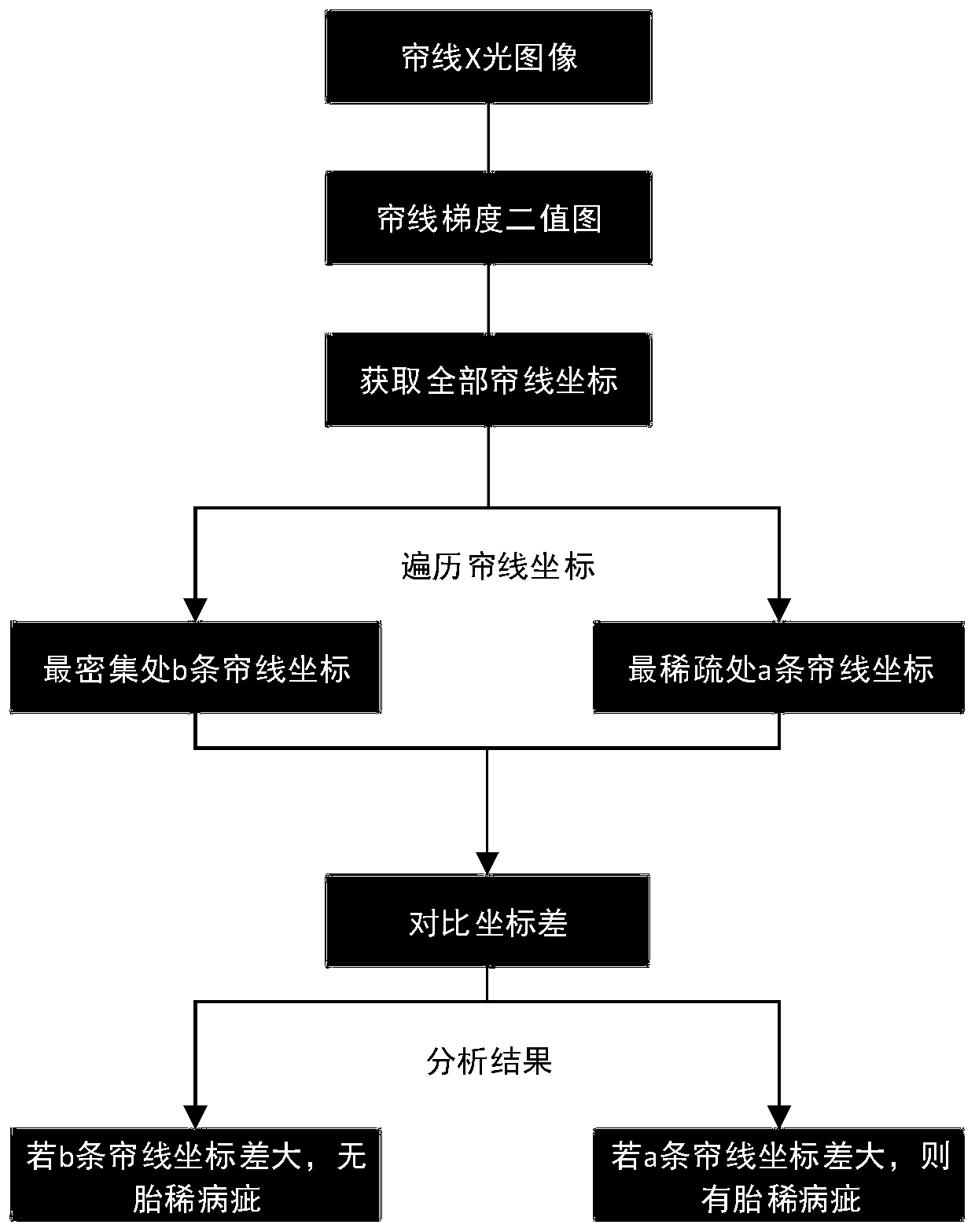

[0029] Such as figure 1 As shown, the example is to detect whether a tire X-ray image has a tire defect, input the X-ray image, and output whether the tire has a tire defect, the specific implementation is as follows:

[0030] (1) Acquire tire X-ray images. This example takes a radial tire as an example. Tires are mainly composed of bead, sidewall, tread and so on.

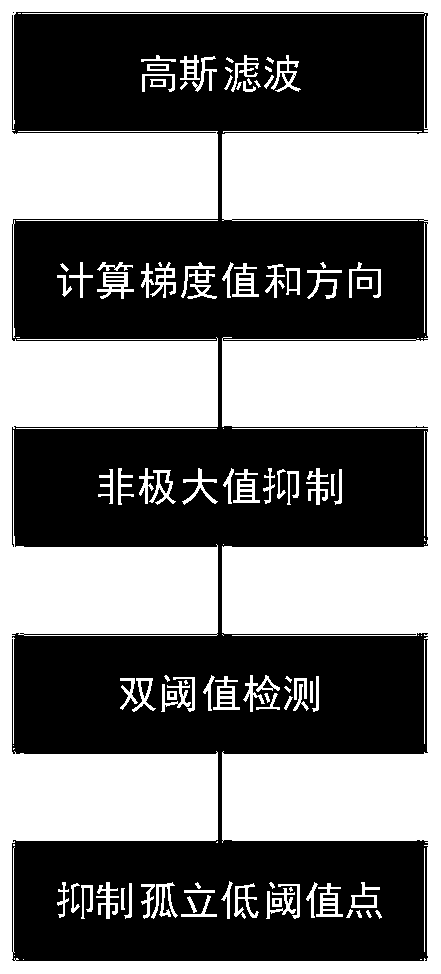

[0031] (2) Image preprocessing, steps such as figure 2 shown. Use the Canny operator to preprocess the image, extract the edge, that is, the tire cord, and obtain the gradient binary image. The specific algorithm steps of the Canny operator to find the edge point are as follows:

[0032] First, the image is smoothed using a Gaussian filter. Image Gaussian filtering can be realized directly through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com