High temperature tensile test resistance furnace capable of controlling cooling process

A technology of tensile test and cooling process, which is applied in the direction of temperature control, furnace control device, non-electric variable control, etc. It can solve the problems that there is no device that can control the cooling, and it is difficult to study the properties of steel in the cooling section of the fire. The effect of temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions provided by the present application will be further described below in conjunction with specific embodiments and accompanying drawings. The advantages and features of the present application will become clearer in conjunction with the following description.

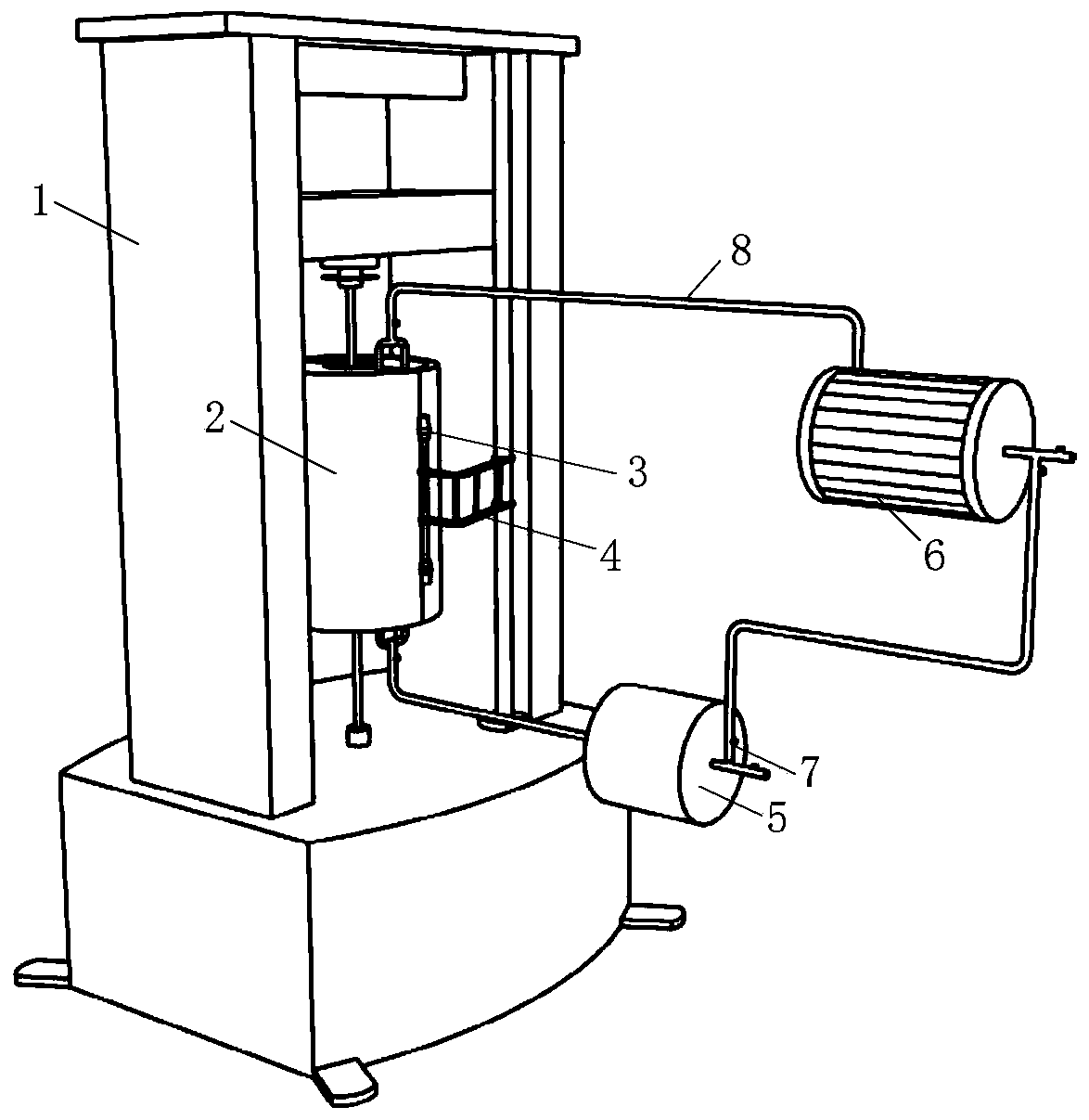

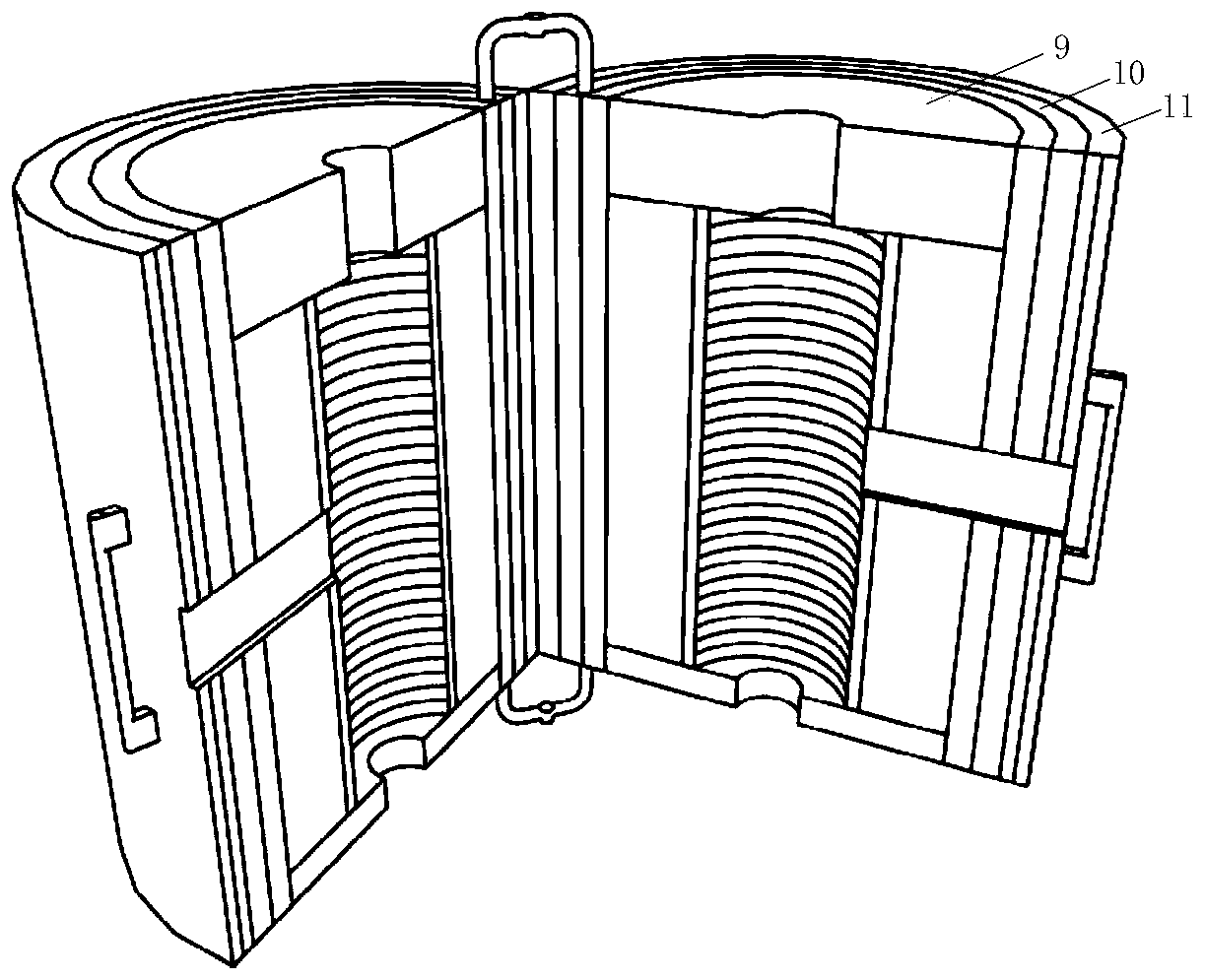

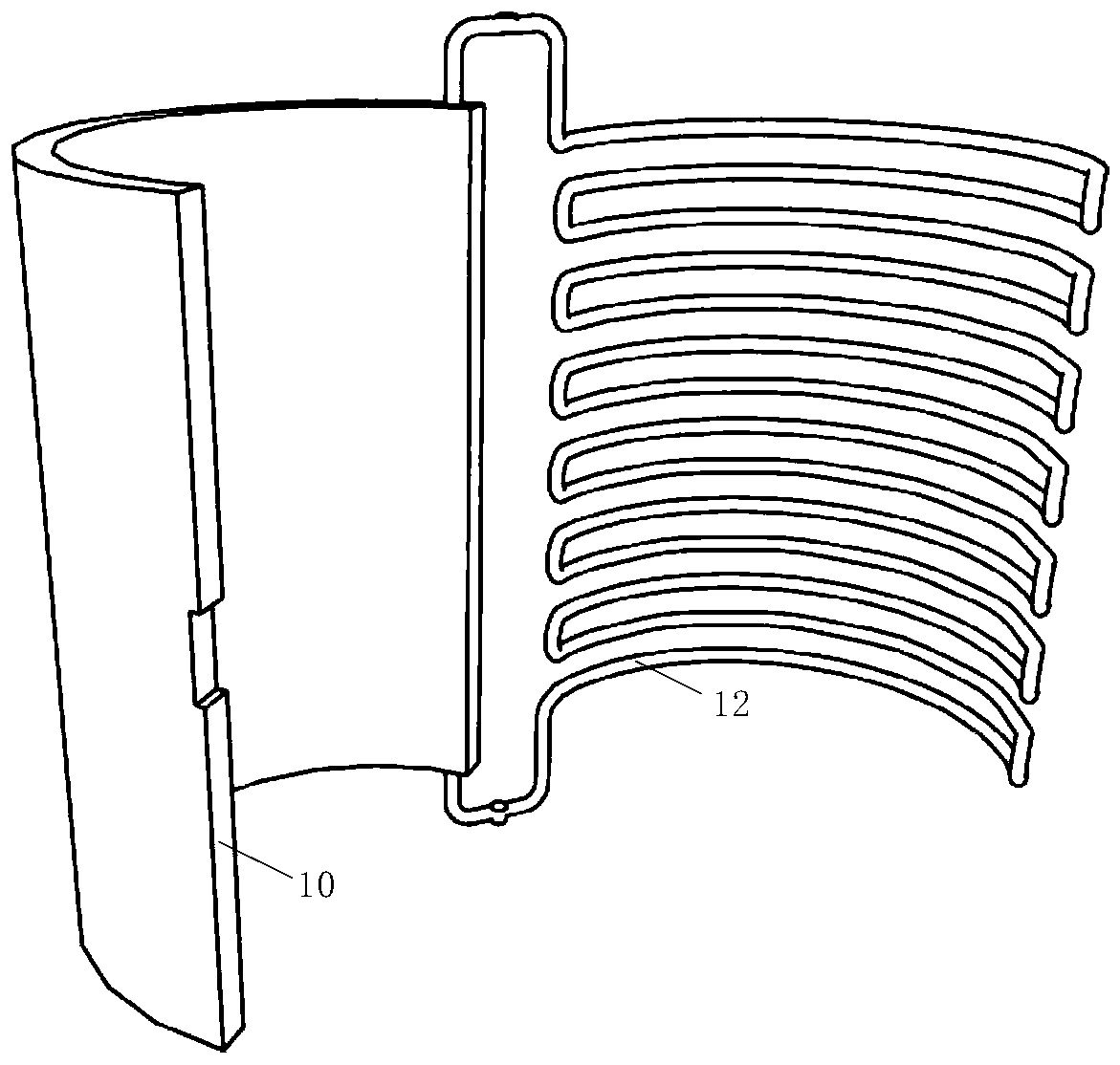

[0029] Such as Figure 1 to Figure 5 As shown, a high-temperature tensile test resistance furnace that can control the cooling process includes a cooling resistance furnace 2, a stretching machine 1, a power unit 5, and a condensation device 6; wherein, the cooling resistance furnace 2 adopts a cylindrical two-half pair In the open structure, the left and right halves of the split are connected by the rotating shaft 3, and the opening and closing of the left and right halves of the cooling resistance furnace 2 can be realized through the rotation of the rotating shaft 3; at the same time, the cooling resistance furnace 2 Installed on the stretching machine 1 through the rotating shaft 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com