Smelting and standing integrated type aluminum smelting furnace

An integrated aluminum melting furnace technology, applied in the direction of furnace, charge, crucible furnace, etc., can solve the problems of high fuel consumption and shorten the service life of aluminum melting furnace, so as to reduce burning loss, save fuel consumption and improve life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

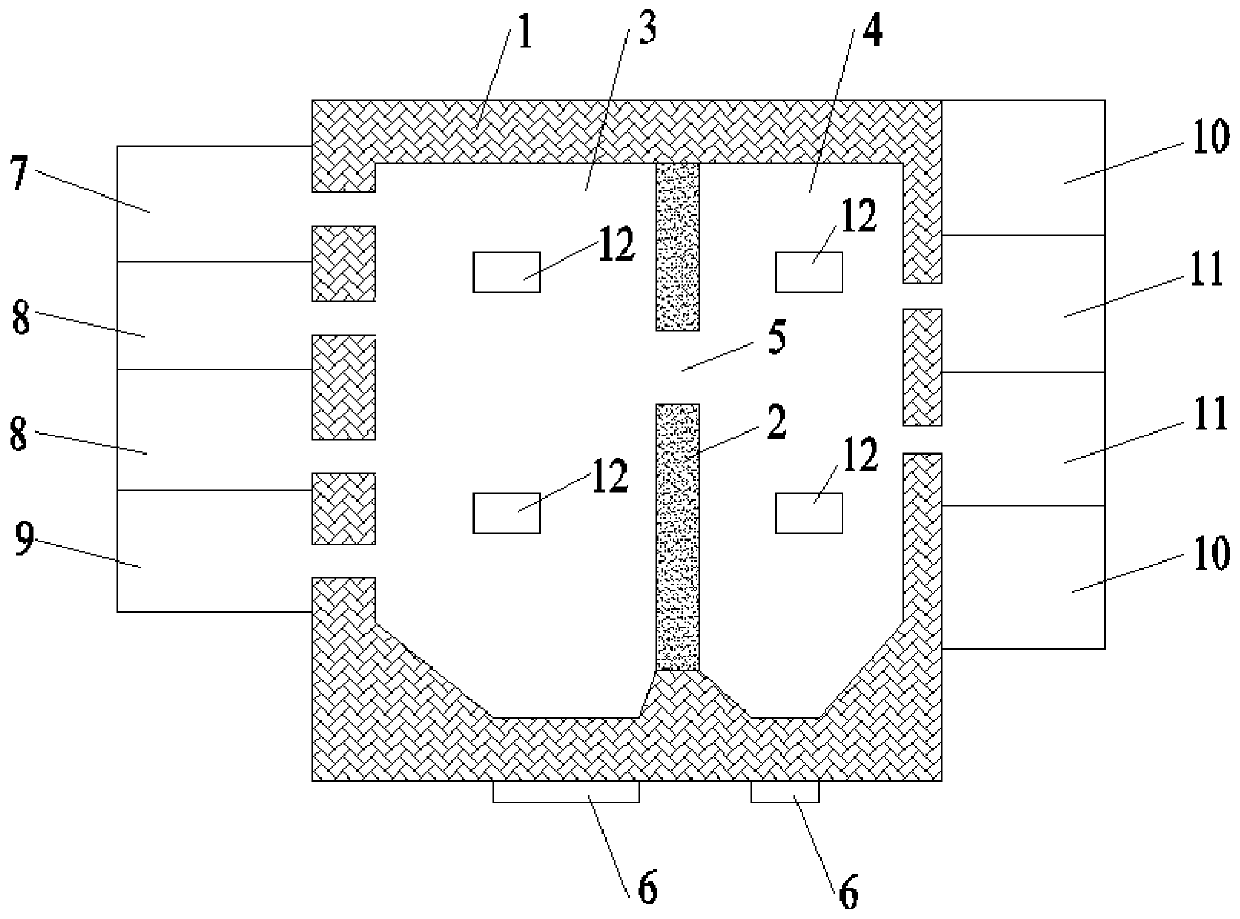

[0012] As shown in the figure: the smelting and static integrated aluminum melting furnace includes a furnace body 1, and the interior of the furnace body 1 forms a furnace. A vertical intermediate wall 2 is arranged inside the furnace body 1, and the intermediate wall 2 divides the furnace into a smelting area 3 and a static area 4, and a channel 5 is opened in the middle of the intermediate wall 2 along the height direction of the intermediate wall 2. Burners 12 are provided on the tops of the smelting zone 3 and the resting zone 4, and the burners 12 can be a group of two, which are used for heat preservation of molten aluminum. There are furnace doors 6 on the furnace body 1 corresponding to the smelting zone 3 and the resting zone 4. On the side wall of the furnace body 1 in the smelting zone 3, there are ingot feeding ports 7, vortex ports 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com