Snow shovel obstacle avoidance device

A technology for obstacle avoidance and snow shoveling, which is applied in snow surface cleaning, construction, and cleaning methods, etc. It can solve the problems of small impact force of segmented obstacle avoidance, small impact force of the mechanism, and large impact force, so as to improve the sensitivity of obstacle avoidance High reliability, reliable reset function, and low impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The patent will be further described in detail below in conjunction with the embodiments and drawings.

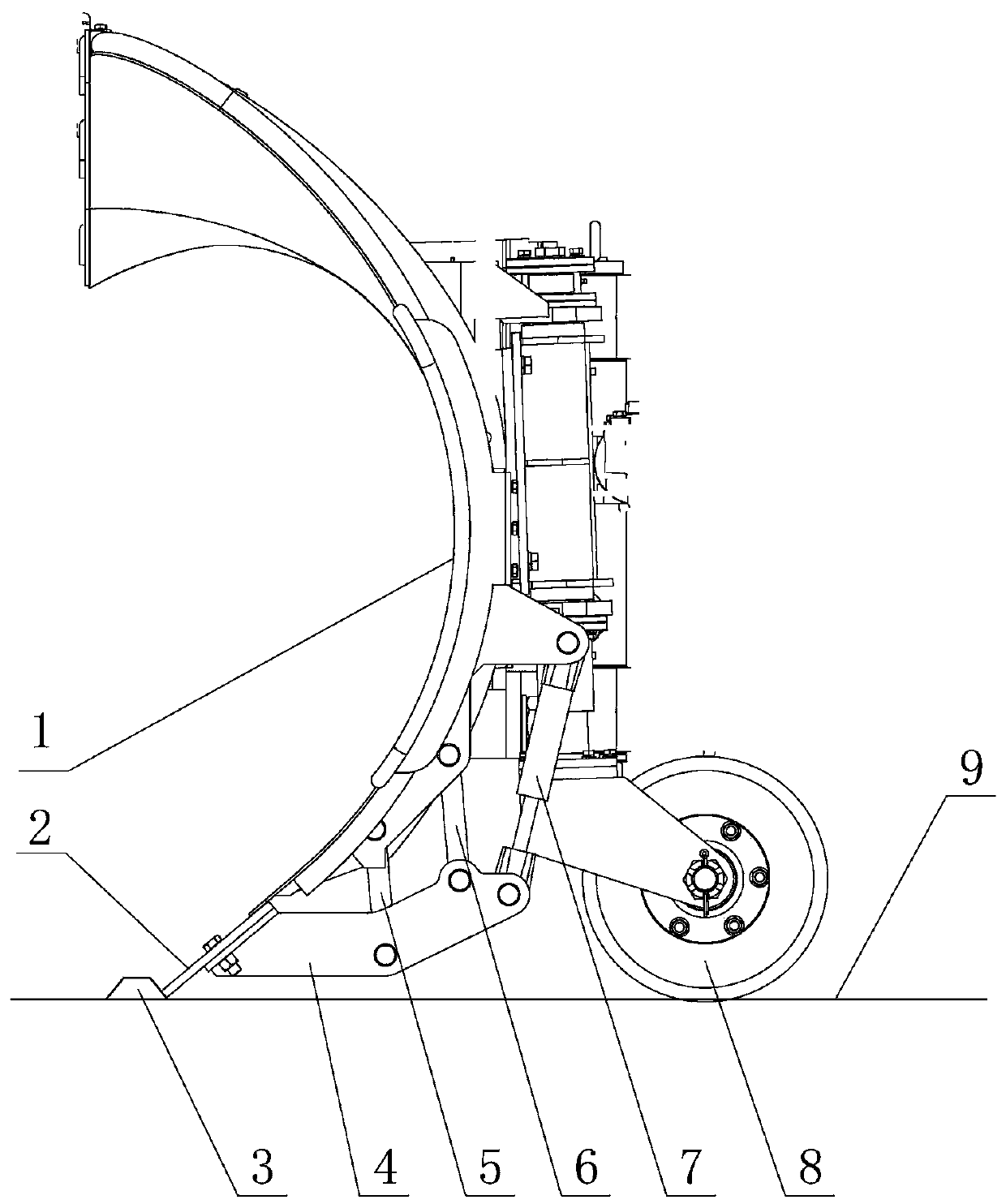

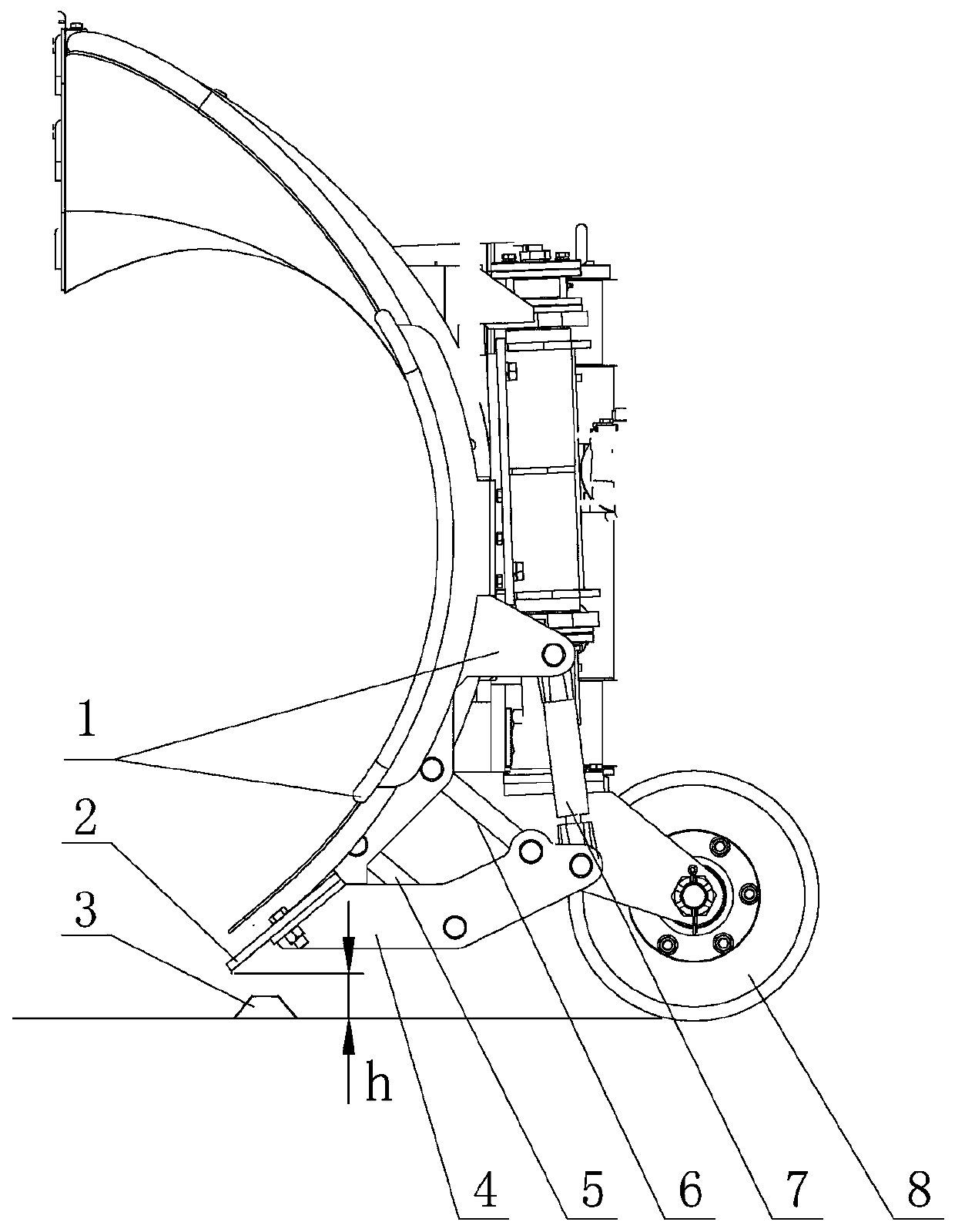

[0028] figure 1 with figure 2 It is a side view of the snow shovel obstacle avoidance mechanism provided by the present invention, which expresses the schematic diagram of the structure principle of "obstacle avoidance" realized by the mechanism action when encountering road obstacles in the working state.

[0029] The meaning of each label is as follows: 1 shovel body, 2 blade, 3 obstacles, 4 bracket, 5 front rocker arm, 6 rear rocker arm, 7 high pressure nitrogen spring, 8 support wheel, 9 road surface.

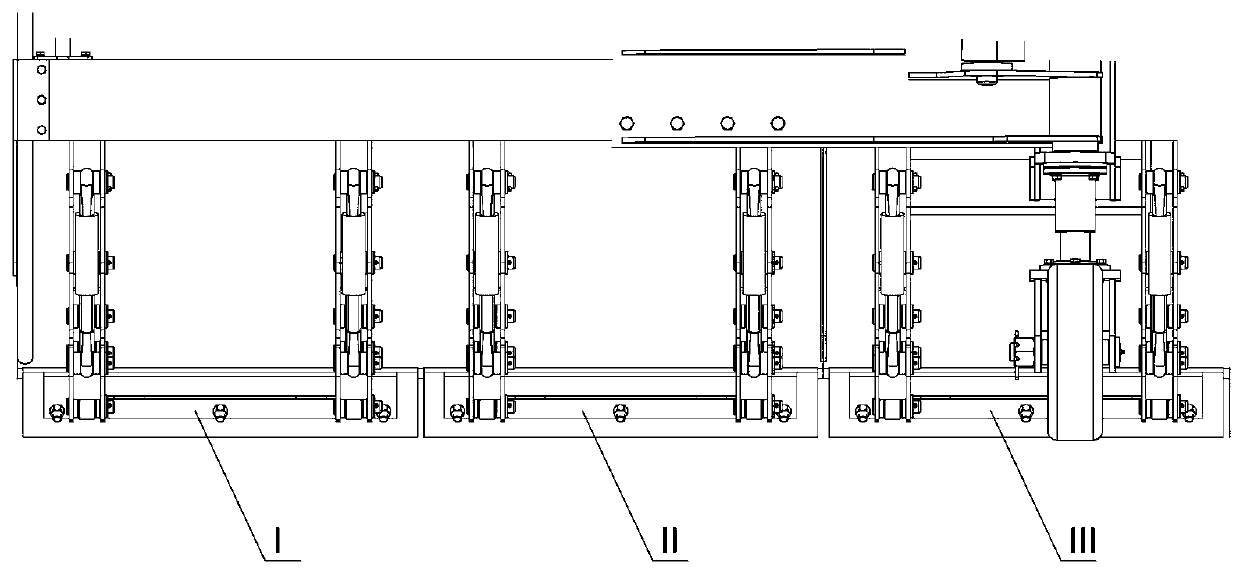

[0030] image 3 It is a partial rear view of the snow shovel obstacle avoidance device of the present invention. The layout of multiple blades in the width direction of the shovel body is combined into a whole (I, II, III...), and the obstacle avoidance action of each group of mechanisms can be independent Completed without interfering with each other.

[0031] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com