Application of alcaligenes as reinforcing agent to mineralized reinforced calcareous sand technology

The technology of Alcaligenes bacteria and reinforcement agent is applied in the field of application of Alcaligenes bacteria as reinforcement agent in the process of mineralization and reinforcement of calcareous sand, which can solve the problems such as pH increase and negative environmental impact, and achieves low environmental impact, Guaranteed drainage and infiltration, widening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

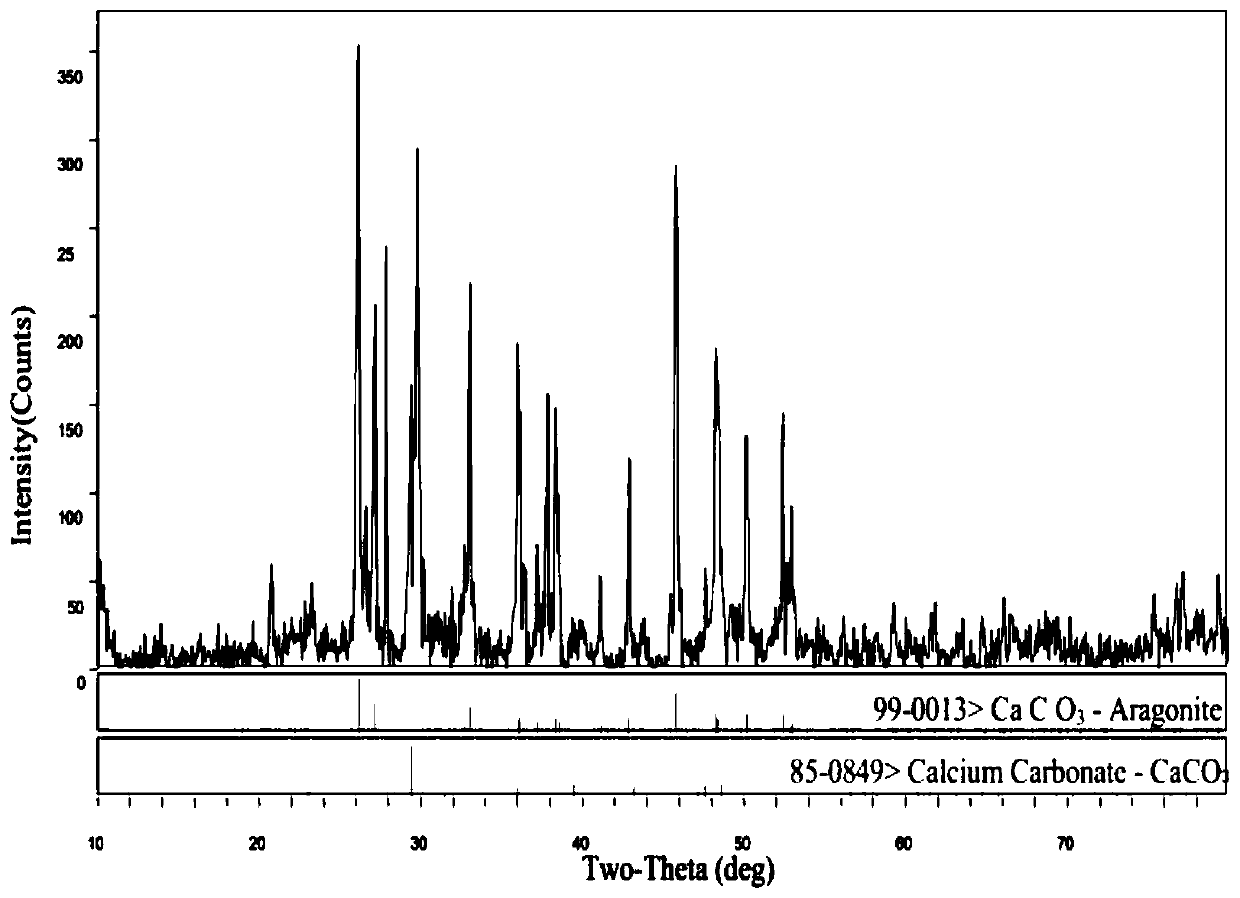

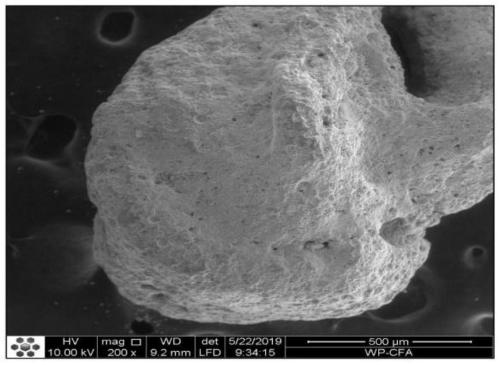

Image

Examples

Embodiment 1

[0038] 1) Add citrate with a volume molar concentration of 0.8mol / l to the strain concentration OD 600 In the Alcaligenes solution of =1.5, a mixed liquid is formed, wherein, in the mixed solution, the volume ratio of Alcaligenes and citrate is 1:1;

[0039] 2) Inject 100mL of the above mixed solution into a Ф5cm×10cm calcareous sand column with a peristaltic pump, and let it stand for 2 hours;

[0040] 3) Use a peristaltic pump to inject 100 mL of CaCl with a volume molar concentration of 0.8 mol / l into the above-mentioned calcareous sand column 2 solution, let it stand for 6 hours, and discharge the remaining solution in the calcareous sand column;

[0041] 4) Repeat steps 2)-3) until the mixed liquid can no longer be injected into the above-mentioned calcareous sand column;

[0042] 5) The above-mentioned reinforced calcareous sand column can be dried, maintained and demoulded. The reinforcement effect of the resulting reinforced calcareous sand column

[0043] The sche...

Embodiment 2

[0045] Step 1) The volume ratio of Alcaligenes and citrate in the mixed solution is 0.5:1, and the others are the same as in Example 1. The reinforcement effect of the obtained reinforced calcareous sand column is shown in Table 1.

Embodiment 3

[0047] Step 1) The volume ratio of Alcaligenes and citrate in the mixed solution is 1.5:1, and the others are the same as in Example 1. The reinforcement effect of the obtained reinforced calcareous sand column is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com