A straight tube capillary used for refrigeration accessories and its processing method

A technology of capillary and straight tubes, applied in the field of straight capillary tubes and their processing, can solve the problems of exposed welds in the welding section, cracked welds, poor safety performance in the refrigeration process, etc., to increase stability, improve safety performance, increase The effect of manipulable space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

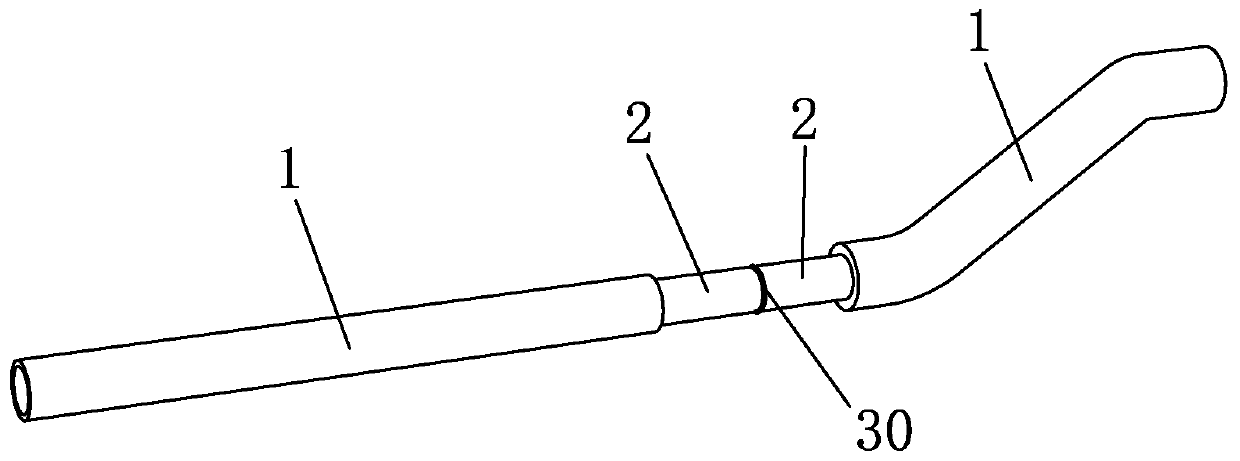

[0048] Such as Figure 1 to Figure 7 As shown, it is a straight capillary tube used for refrigeration accessories in the present invention, which includes at least two sections of tube body 1 , and two adjacent sections of tube body 1 are welded by welding section 2 .

[0049] The present invention also includes a weld seam protection device 3 , which is detachably hugged at the weld seam 30 between the welding sections 2 . The welding seam protector 3 is equipped with an adjustment connection device 4, which is used for fixed connection between two adjacent sections of straight capillary tubes connected as a whole.

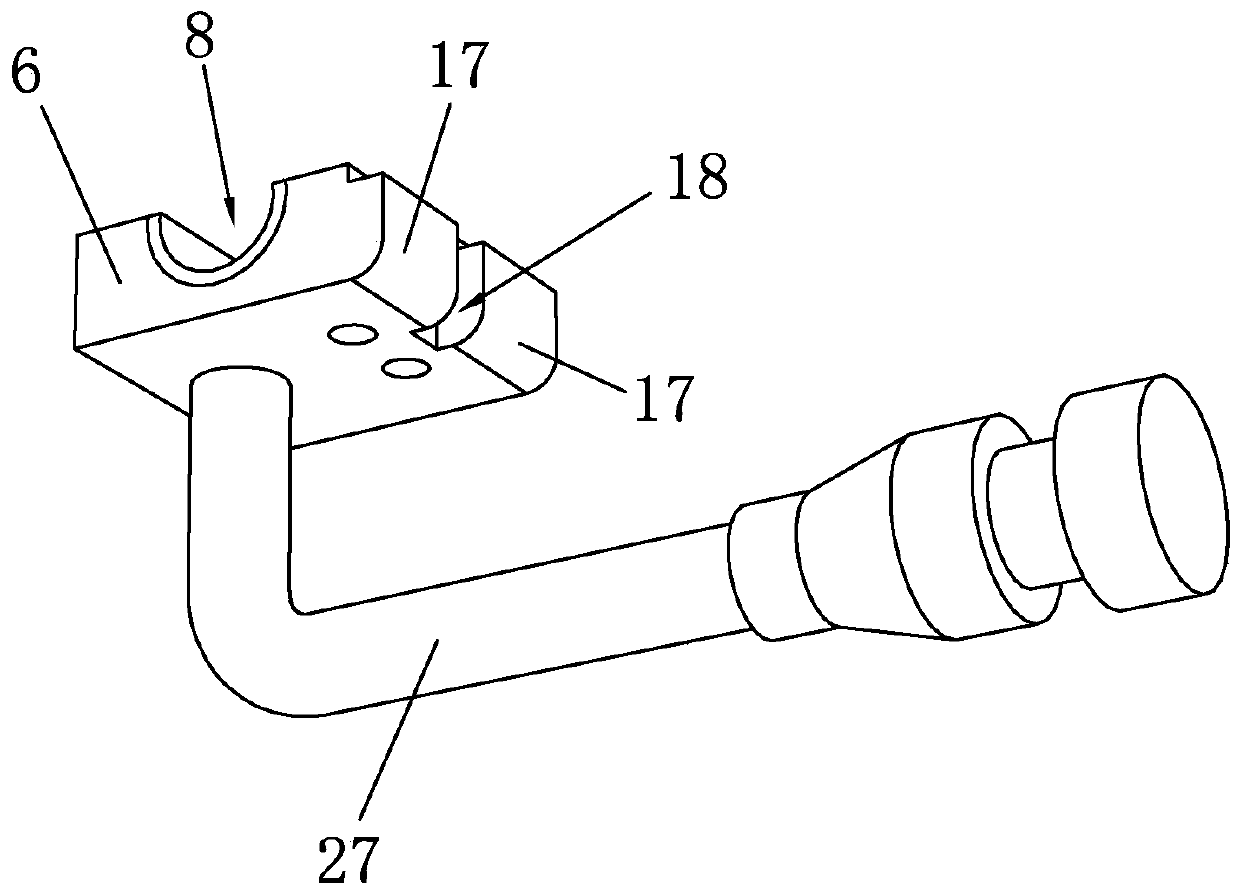

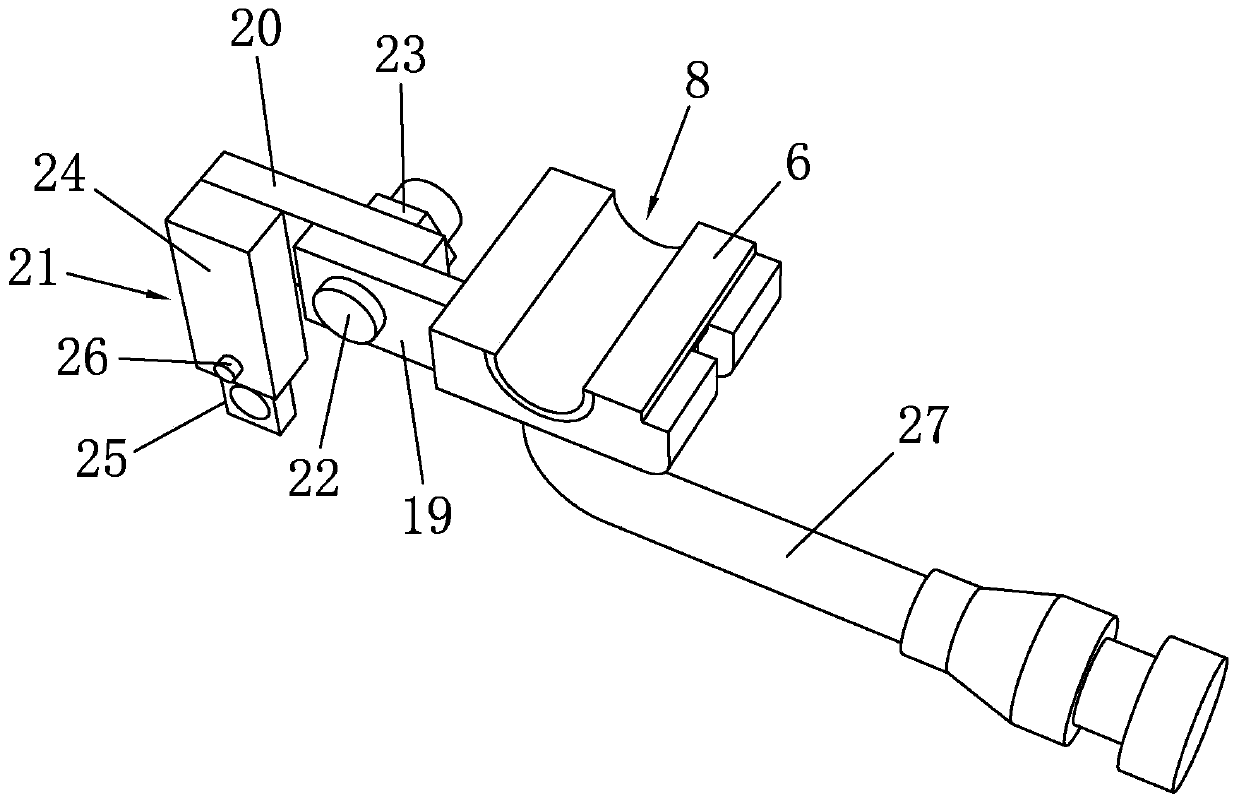

[0050] The weld protector 3 includes an upper end plate 5 and a lower end plate 6, the upper end plate 5 is provided with a first arc groove 7, the lower end plate 6 is provided with a second arc groove 8, and a clip is provided between the upper end plate 5 and the lower end plate 6. The tightening device 9, through the clamping action of the clamping device 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com