Adhesive pressure forming equipment

A forming equipment and pressure technology, applied in the direction of presses, manufacturing tools, etc., can solve problems such as difficult to meet viscous pressure forming, poor equipment reliability, and inability to give full play to viscous pressure forming, etc., to achieve the effect of non-isostatic pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

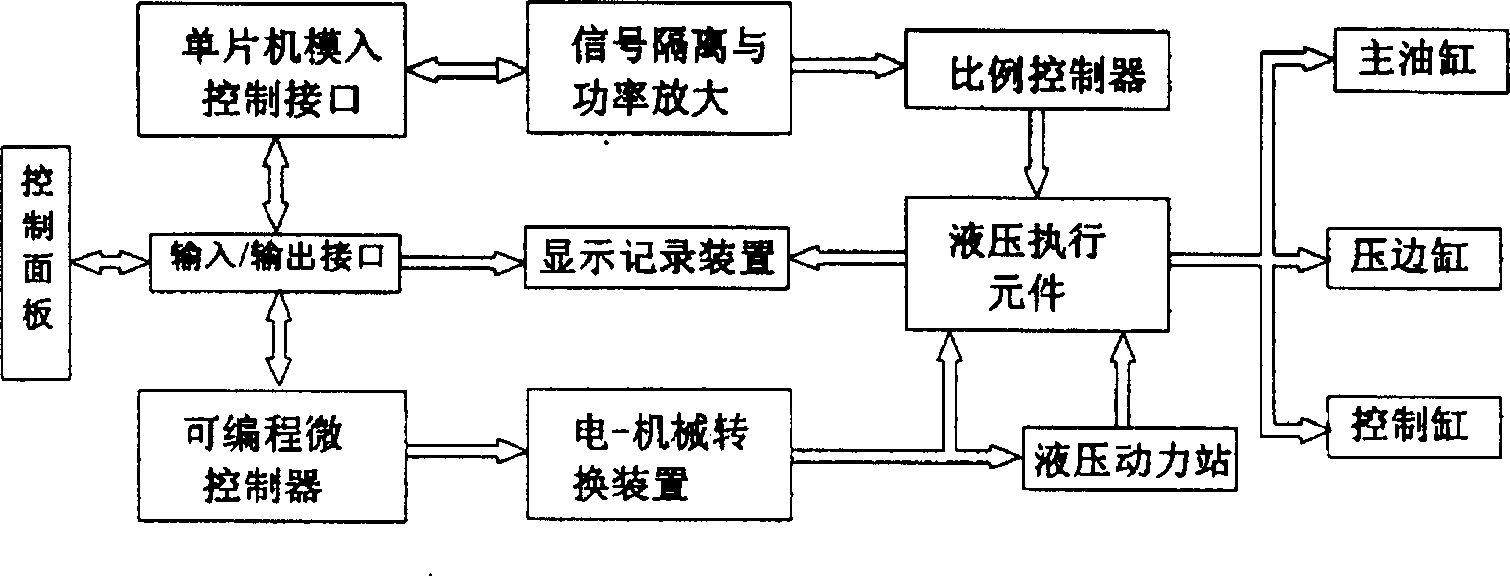

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

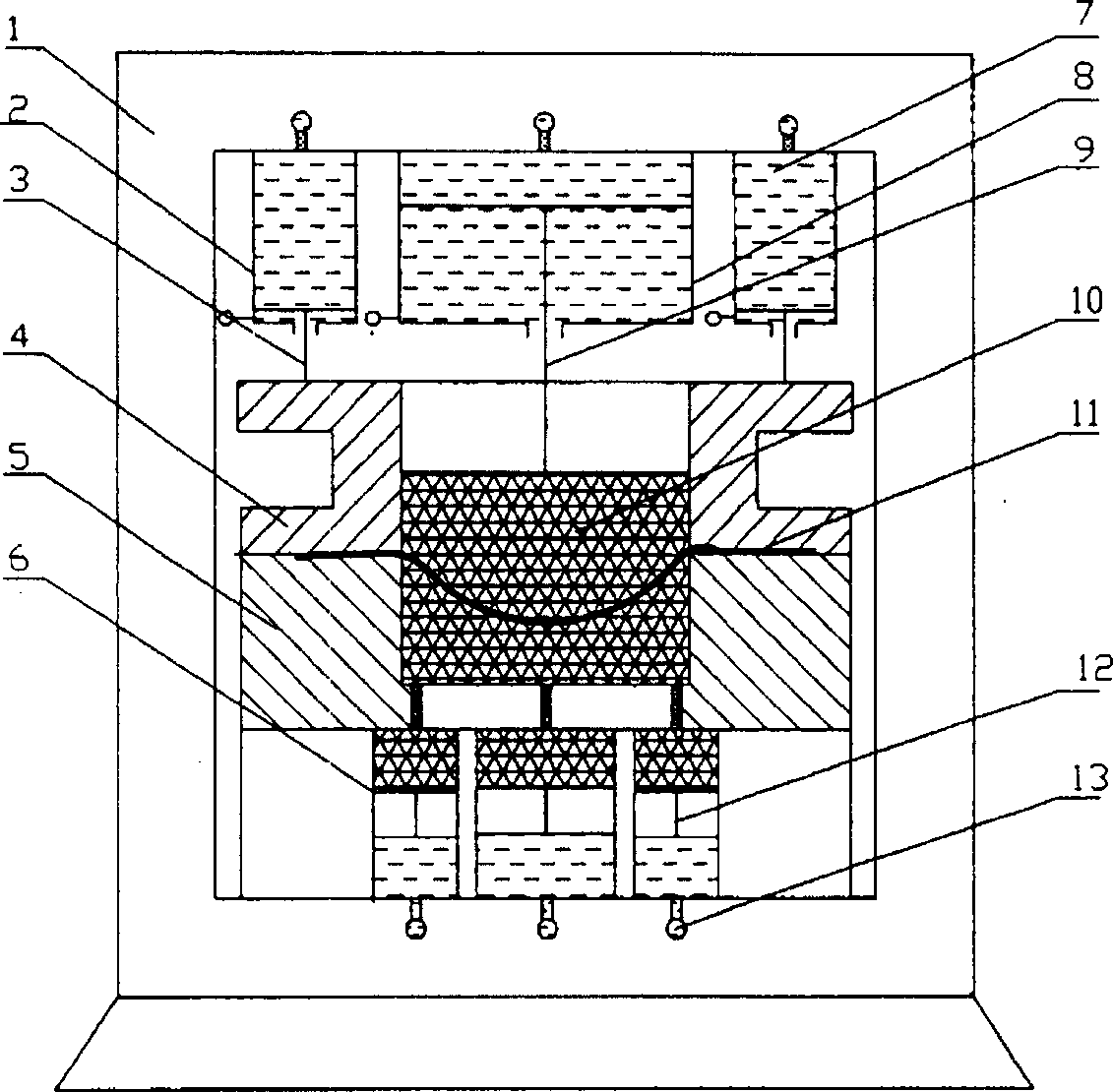

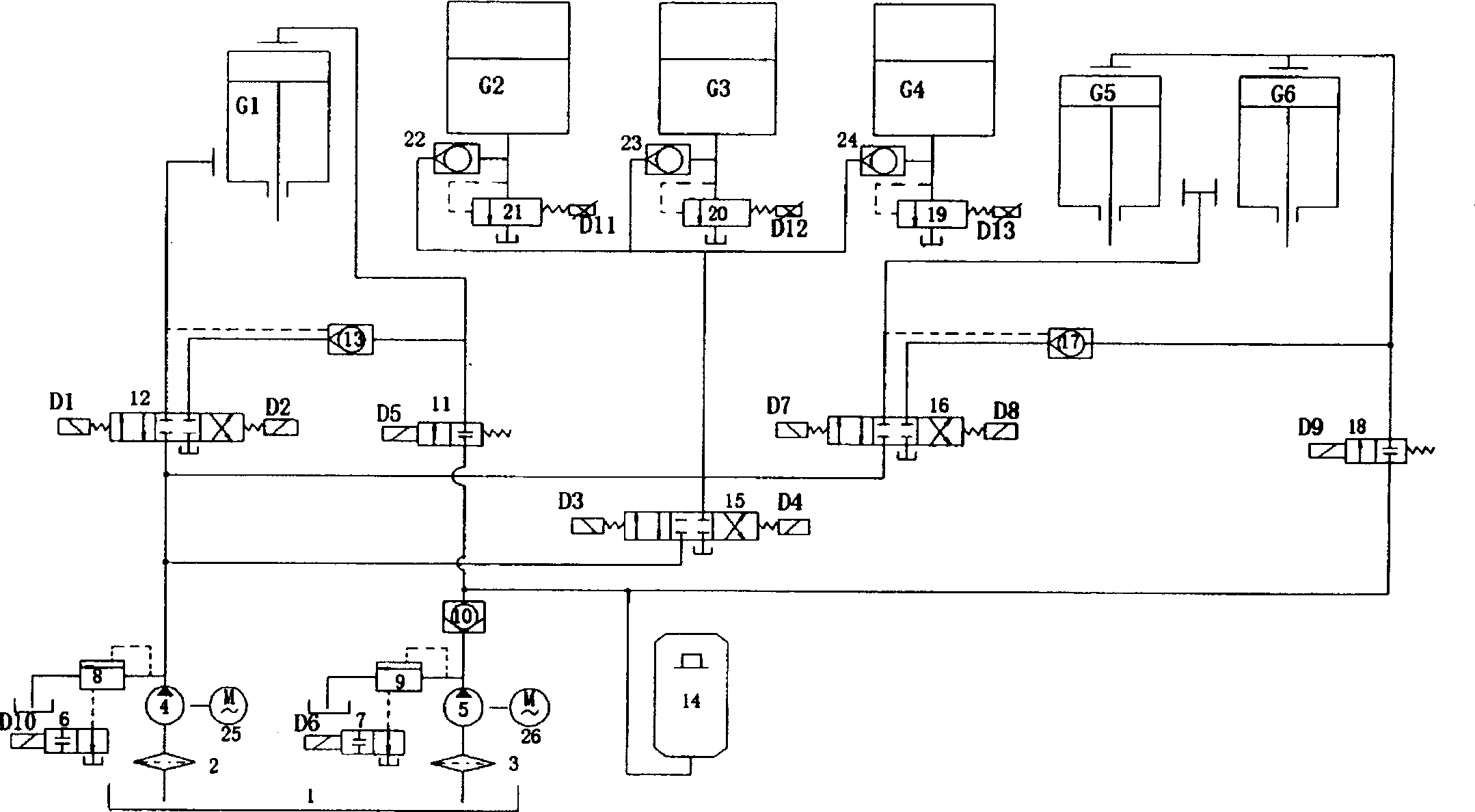

[0009]The inner diameter of the main pressure cylinder is Φ180mm, the diameter of the piston rod is Φ150mm, and the piston stroke is 250mm, and it is installed in the upper center of the inner frame of the frame; On both sides of the upper part of the inner frame of the rack; the inner diameter of the central control cylinder is Φ120 mm, and the piston stroke is 180 mm, which is installed in the center of the lower part of the inner frame of the rack; the inner diameter of the oil cylinder of the peripheral control cylinder is Φ80 mm, and the piston stroke is 180 mm, which is installed on the rack The outer circumference of the lower part of the inner frame, the distribution of six etc.; the inner cavity diameter of the lower die is Φ150 mm, the depth is 145 mm, and it is installed on the control cylinder; the inner cavity diameter of the upper die is Φ150 mm, the effective depth is 250 mm, and it is installed under the main oil cylinder; The inner window size: height 1605 mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com