Spray drying machine used for solid dye production

A spray dryer and dye technology, applied in spray evaporation, evaporator accessories, dispersed particle separation, etc., can solve the problems of lack of air filtration, inability to clean dye particles, easy clogging of finished dye particles, etc., to ensure safety and prevent miscellaneous Mixing of materials and dyes to overcome the effect of unsmooth feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

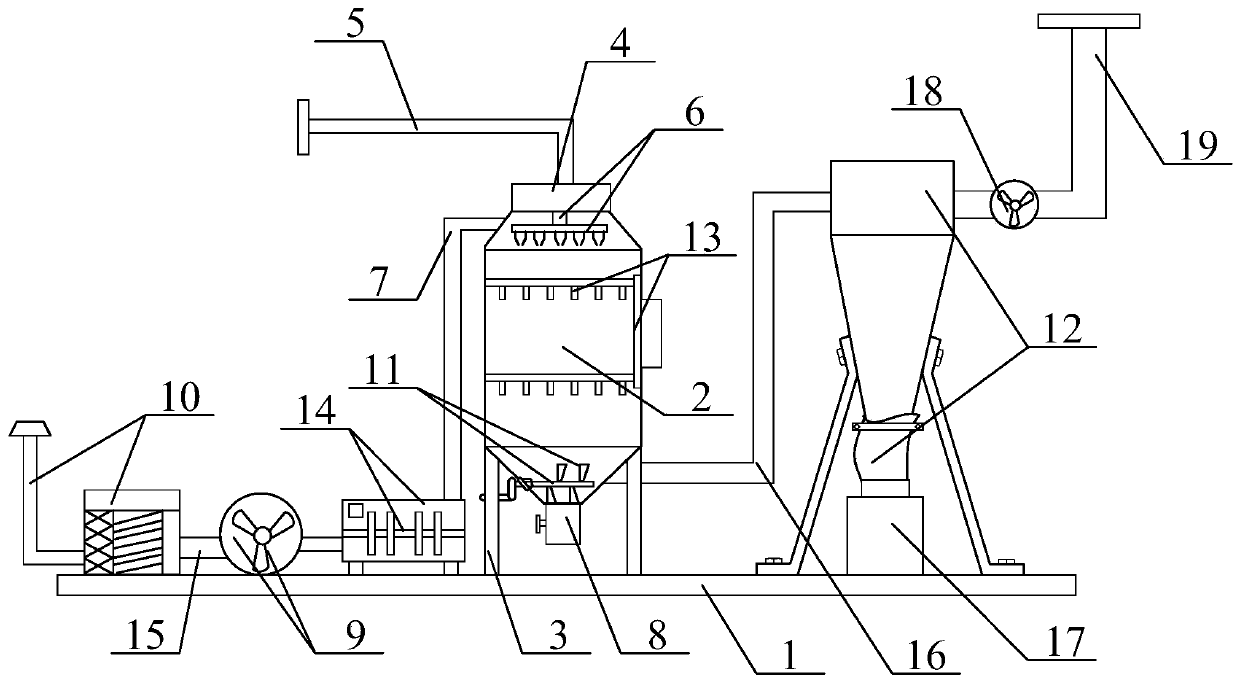

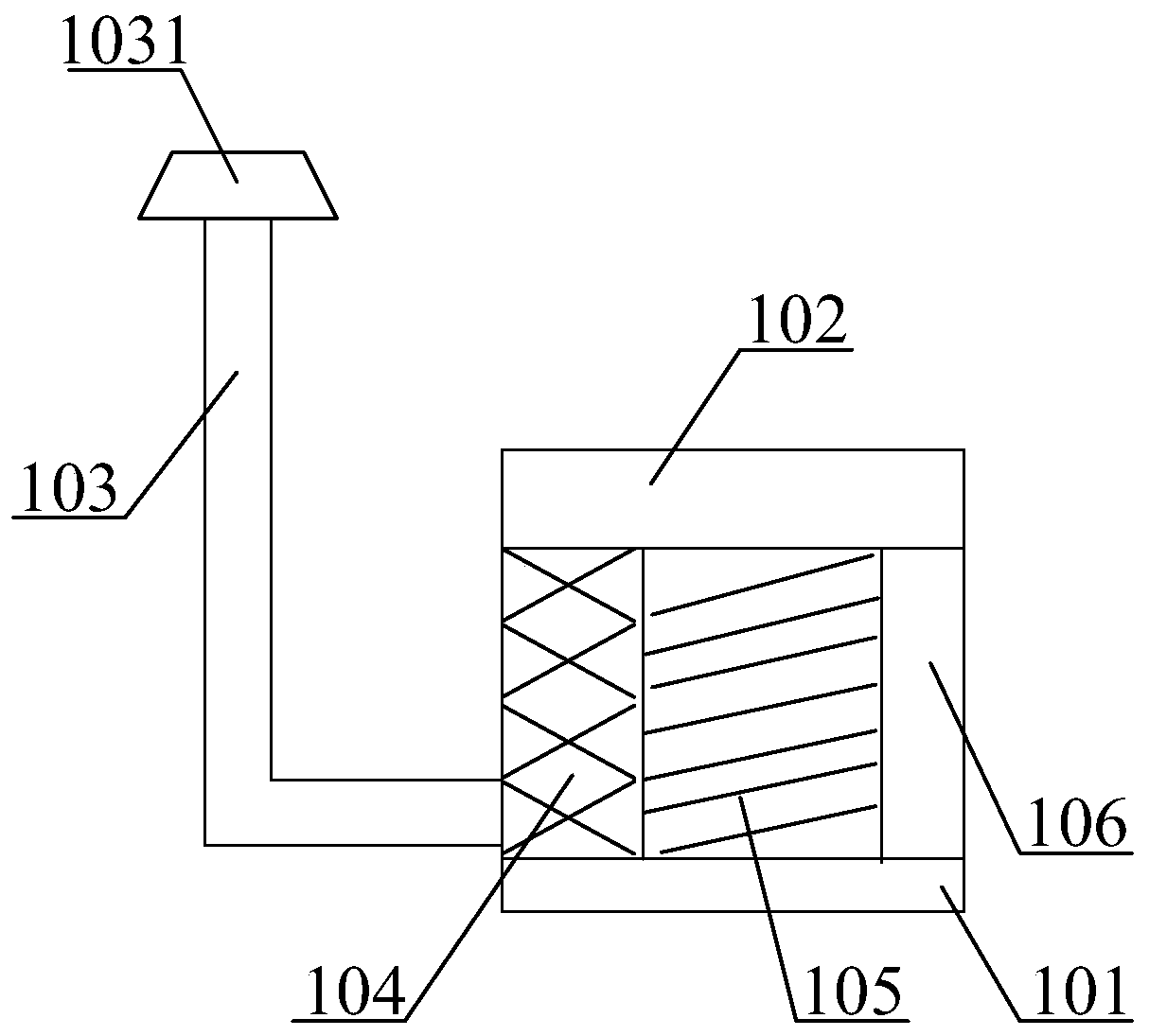

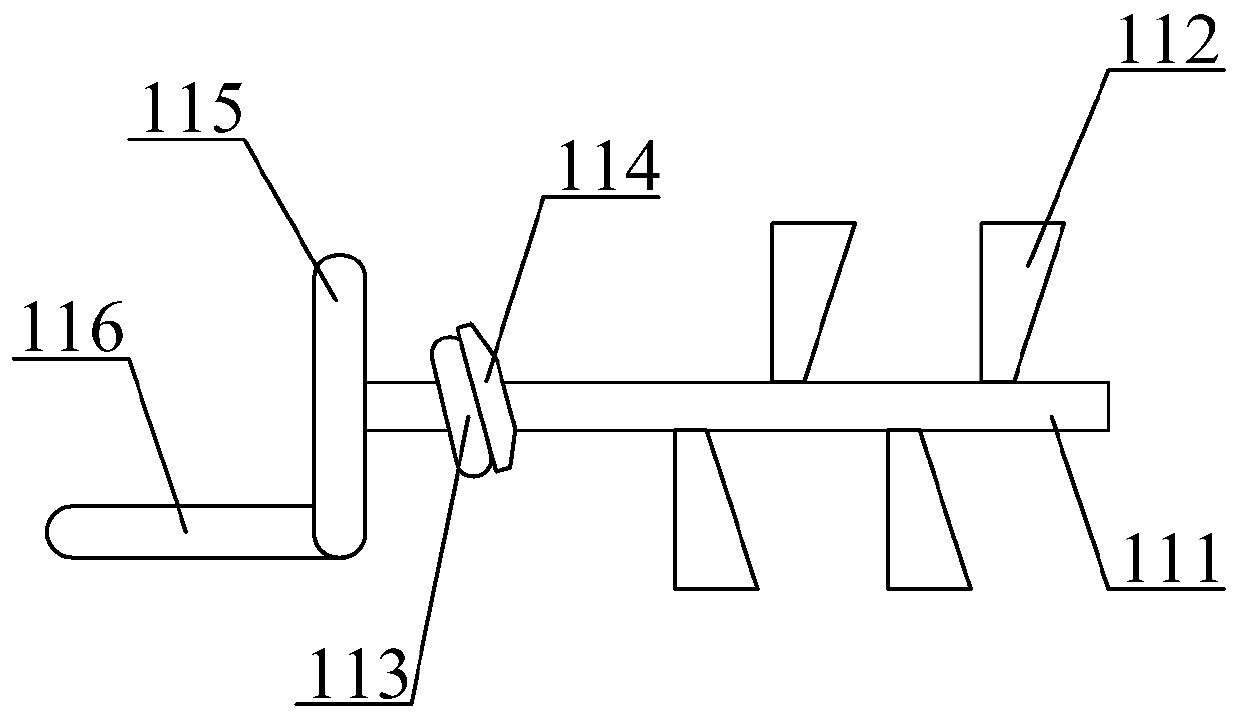

[0065] see Figure 1-Figure 6 As shown, the present invention provides a spray dryer for solid dye production, comprising a support base plate 1, a drying tank 2, a support column 3, an atomizer 4, a dye liquid inlet pipe 5, a spray nozzle 6, a hot air conduit 7, a discharge Valve 8, blower 9, cold air purification filter box structure 10, anti-blocking manual material shifting sheet structure 11, cyclone separator structure for discharge and dust prevention 12, ultrasonic vibration particle shake-off ring structure 13, air heating box structure 14, guide Gas connection pipe 15, secondary separation conduit 16, collection box 17, induced draft fan 18 and exhaust gas discharge connection pipe 19. One end of the support column 3 is bolted to the lower surface of the drying tank 2, and the other end is bolted to the middle of the upper surface of the supporting base plate 1; the atomizer 4 is bolted to the upper surface of the drying tank 2; the dye inlet pipe 5 is bolted to On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com