A kind of injection filling microsphere preparation and preparation method thereof

A technology of microspheres and microspheres, which is applied in the fields of medical cosmetology and biomedicine, can solve the problems of permanent injection fillers such as long-term foreign body reaction, aseptic inflammation, and short maintenance time, so as to achieve good filling effect, prevent degradation, The effect of moderate degradation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

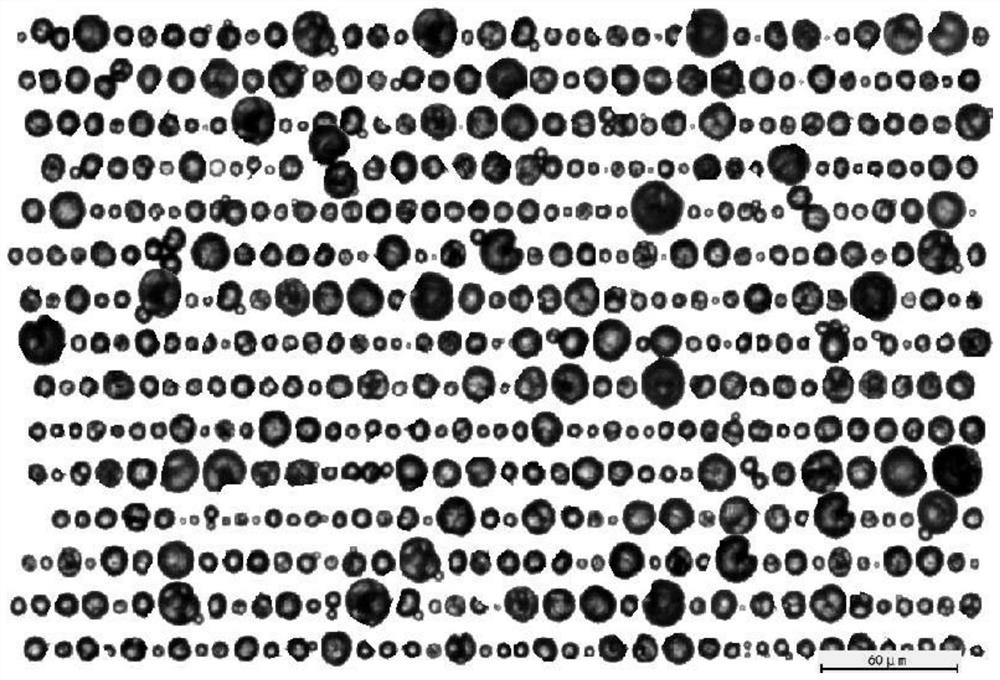

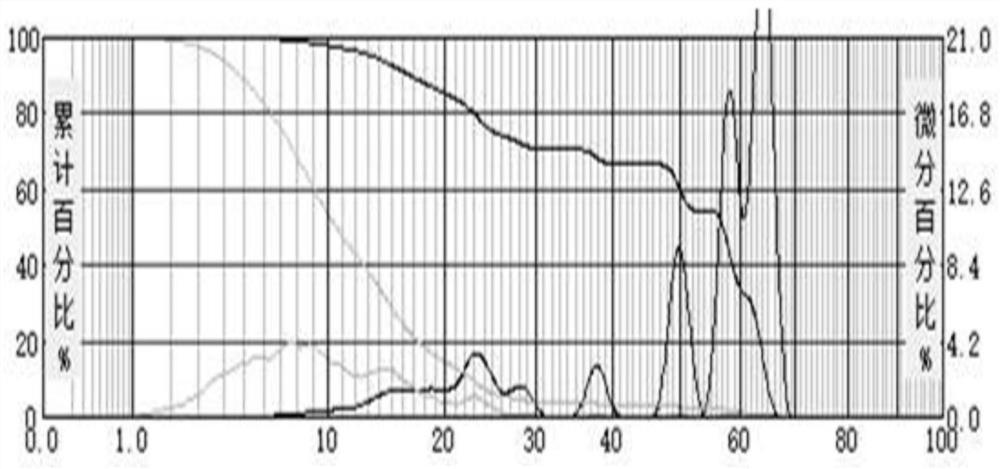

Image

Examples

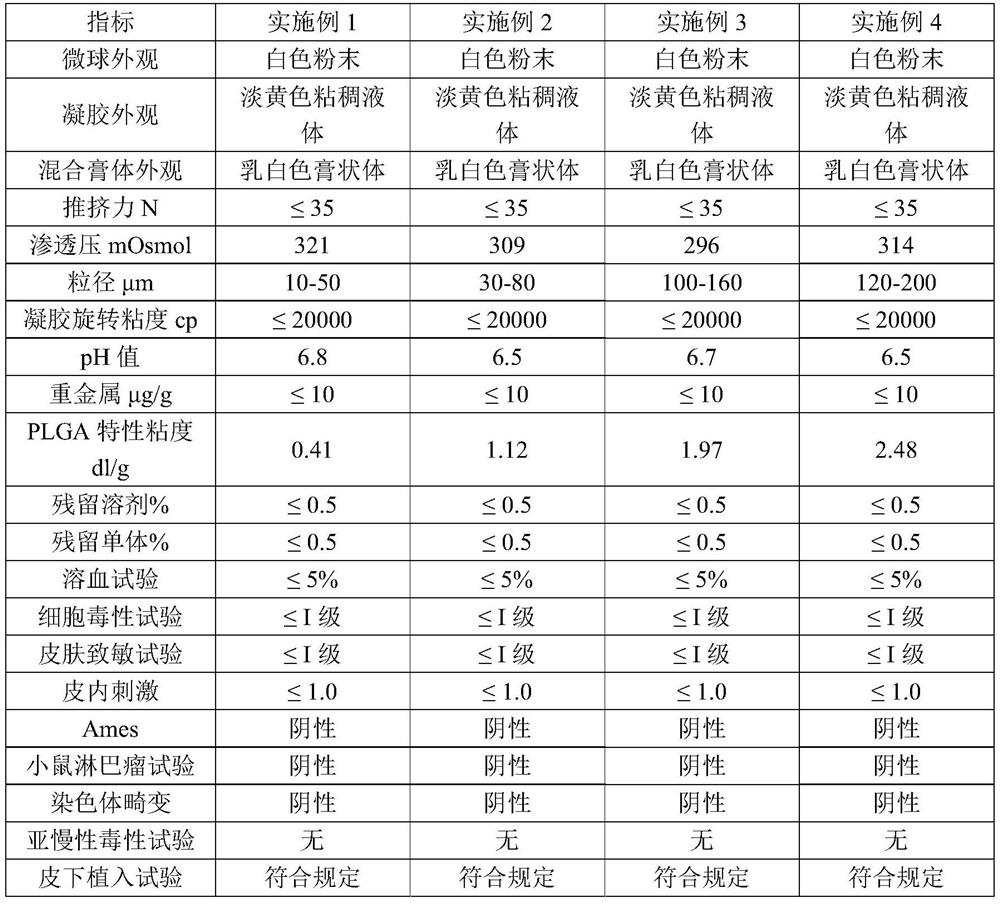

Embodiment 1

[0056] The preparation of embodiment 1 microspheres and gel

[0057] To 20L mass concentration of 0.2% polyvinyl alcohol 1788 (low viscosity type) aqueous solution, add 6L mass concentration of 2% polylactide (intrinsic viscosity is 0.4dl / g) dichloromethane solution, stir for 3 hours, The stirring speed is 350rpm, and the mixture in the reactor is released. Suction filtration, vacuum drying, ready for filling.

[0058] Add 30 g of mannitol and 30 g of hydroxymethyl methylcellulose sodium into 1 L of water for injection, stir at 30° C. at a stirring speed of 350 rpm, and form a gel after fully dissolving.

Embodiment 2

[0059] The preparation of embodiment 2 microspheres and gel

[0060] To 10L mass concentration of 0.5% polyvinyl alcohol 1788 (low viscosity type) aqueous solution, add mass concentration of 10L5% polylactide (intrinsic viscosity is 1.0dl / g) chloroform solution, stir for 8 hours, stirring speed 500rpm , release the mixture in the reactor. Suction filtration, vacuum drying, ready for filling.

[0061] Add 50 g of glucose and 30 g of hydroxypropyl methylcellulose sodium into 1 L of water for injection, stir at 20° C. at a stirring speed of 350 rpm, and form a gel after fully dissolving.

Embodiment 3

[0062] The preparation of embodiment 3 microspheres and gel

[0063] To 20L mass concentration is 1.0% polyvinyl alcohol 1788 (low viscosity type) aqueous solution, add 15L mass concentration as 10% polylactide (intrinsic viscosity is 2.0dl / g) ethyl acetate solution, stir 15 hours, The stirring speed is 650rpm, and the mixture in the reaction kettle is released; it is filtered, vacuum-dried, and prepared for filling.

[0064] Add 26 g of glycerin and 28 g of sodium carboxymethylcellulose into 1 L of water for injection, stir at 50° C. at a stirring speed of 350 rpm, and form a gel after fully dissolving.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com