Cam driven pin-pricking type rubber cutting machine

A technology for driving needles and rubber tapping machines, applied in forestry, application, agriculture, etc., can solve the problems of large bark cutting consumption, difficult operation, complex structure, etc., and achieve the effect of simple structure, convenient operation and large driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

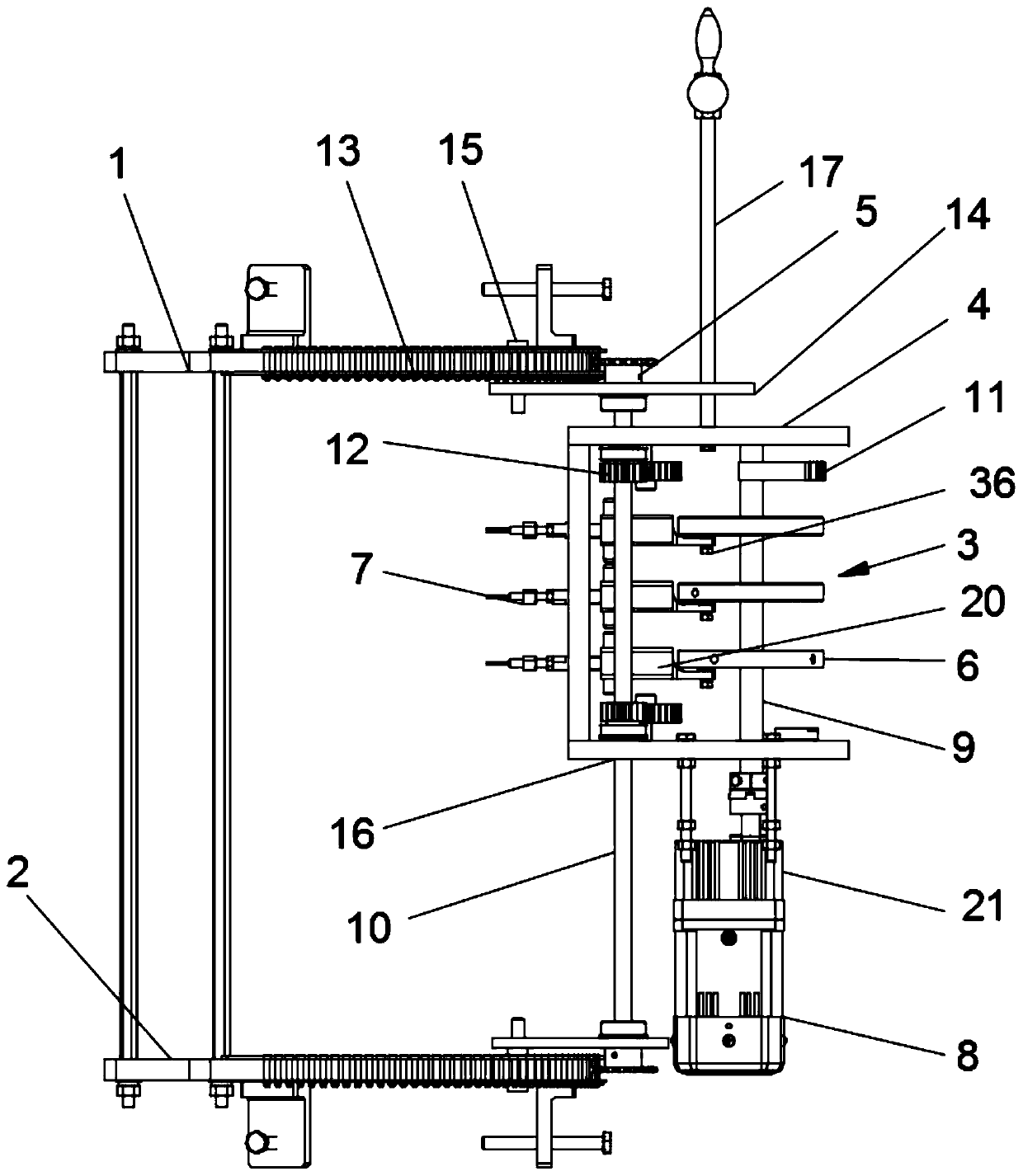

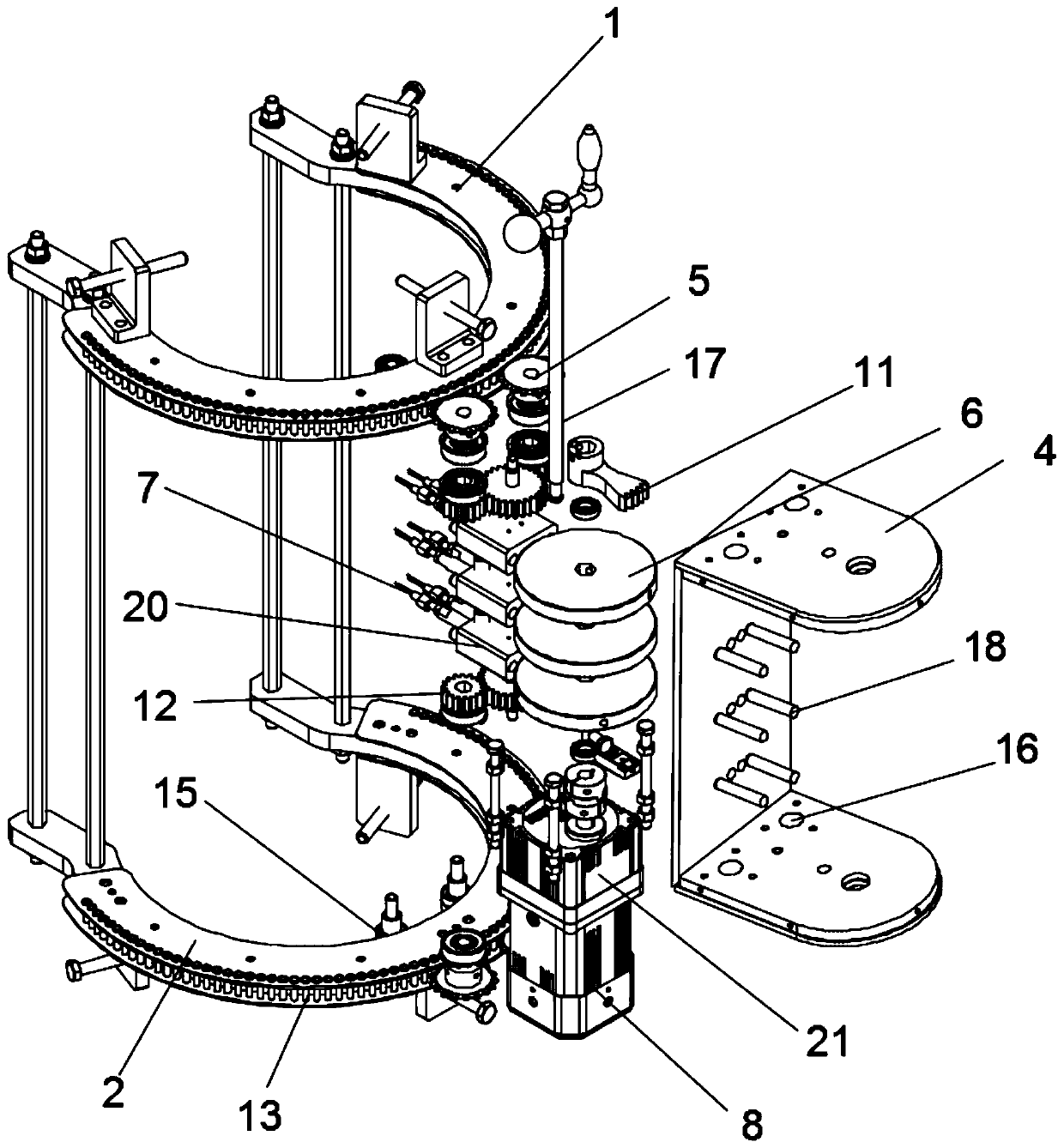

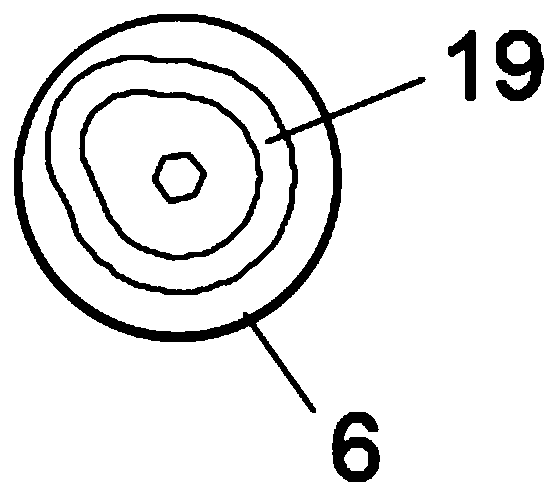

[0024] see Figures 1 to 3 , a cam-driven needle-punched rubber tapping machine, comprising an upper track 1, a lower track 2 and a moving assembly 3, the upper track 1 and the lower track 2 are fixed on a rubber tree, and the moving assembly 3 includes a moving frame 4, a driving wheel 5 , cam 6, needle 7 and motor 8, described moving frame 4 is slidingly connected with described needle 7, and described cam 6 is connected with described moving frame 4 through first rotating shaft 9 rotation, and described needle 7 is on described cam 6 Driven to reciprocate, the motor 8 drives the first rotating shaft 9 to rotate, and the upper and lower ends of the moving frame 4 are respectively provided with the driving wheels that drive the moving assembly 3 to move along the upper track 1 and the lower track 2 5. The driving wheel 5 is rotationally connected with the moving frame 4 through the second rotating shaft 10, the first rotating shaft 9 is provided with sector teeth 11, and the ...

Embodiment 2

[0032] see Figures 4 to 5 , The difference between this embodiment and Embodiment 1 is that the needle 7 includes a sleeve 22, a coil spring 23, a stop bar 24 and a needle bar 25 with a tip, and the needle bar 25 and the sleeve 22 slide connection, the sleeve 22 is provided with the coil spring 23, one end of the coil spring 23 is connected to the needle bar 25, and the other end is connected to the sleeve 22, and the needle bar 25 is connected to the sleeve 22 One end of the sleeve 22 is provided with a bar groove 26, the inner side wall of the sleeve 22 is provided with a limit tooth groove 13, the limit rod 24 is rotatably connected in the bar groove 26, and one end of the limit rod 24 is set There is a limit tooth block 29 for snapping into the limit tooth groove 13, and the other end is provided with a trigger block 30 protruding from the side surface of the needle bar 25, and the bar groove 26 is provided with a pusher to push the position limit. The block snaps into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com