Preheating method for molten salt tank of thermal storage system of photothermal power station

A technology of heat storage system and photothermal power station, which is applied in the direction of solar heating system, solar heat storage, solar thermal power generation, etc., and can solve the problem of incomplete preheating time storage of heat sources in preheating structure layout, uneven preheating temperature, pollutants, etc. High emissions and other issues, to avoid freezing accidents, reduce the cost of temporary materials, and enhance the effect of air disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0031] The method for preheating the molten salt tank of the heat storage system of the photothermal power station includes the following aspects,

[0032] 1. Selection of equipment: The selection of the preheating gas furnace is determined by analyzing the capacity of the molten salt tank.

[0033] The type of gas furnace should be selected according to the temperature rise requirements, and the fuel can be selected from natural gas, propane gas and other non-pollutant gases after combustion.

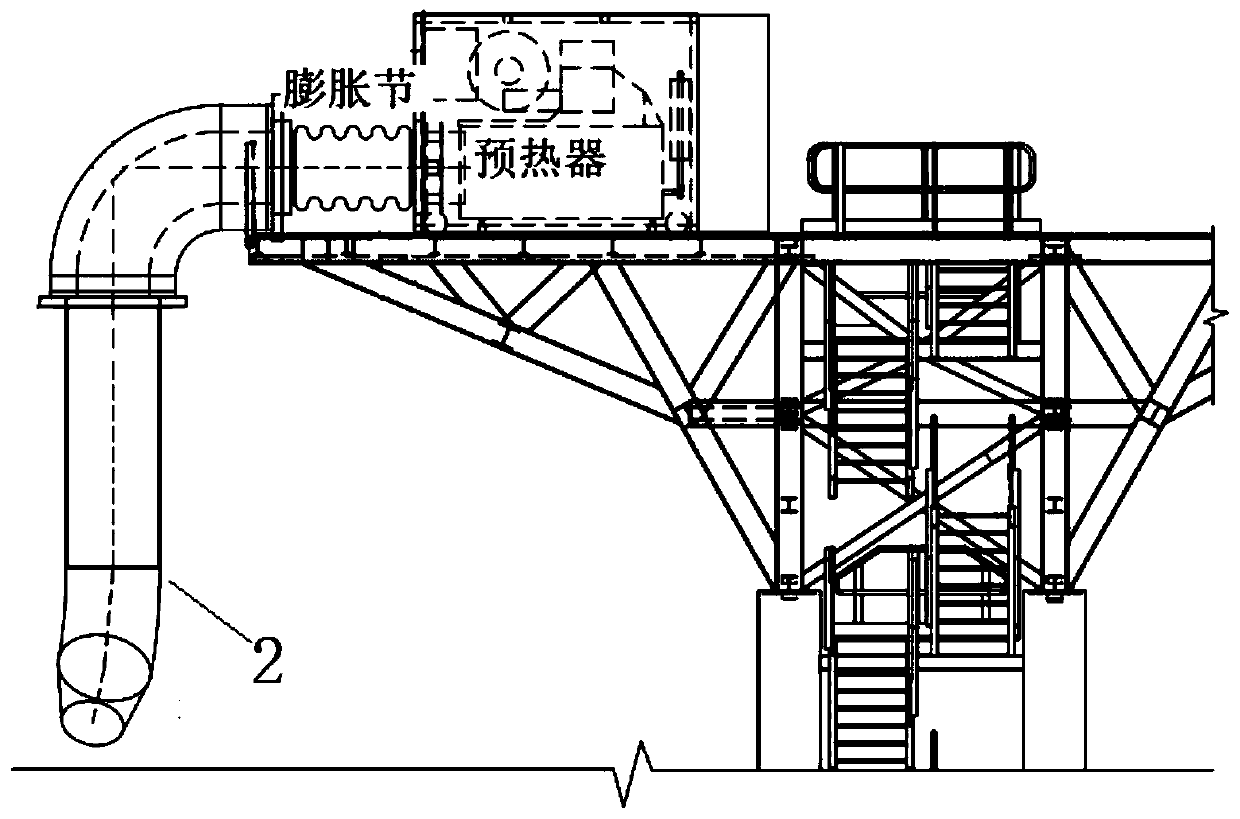

[0034] 2. Design of temporary preheating pipeline: Determine the temporary pipeline layout of the preheating system through the analysis of molten salt tank and flue gas flow state.

[0035] 3. Arrangement of preheating system of molten salt tank:

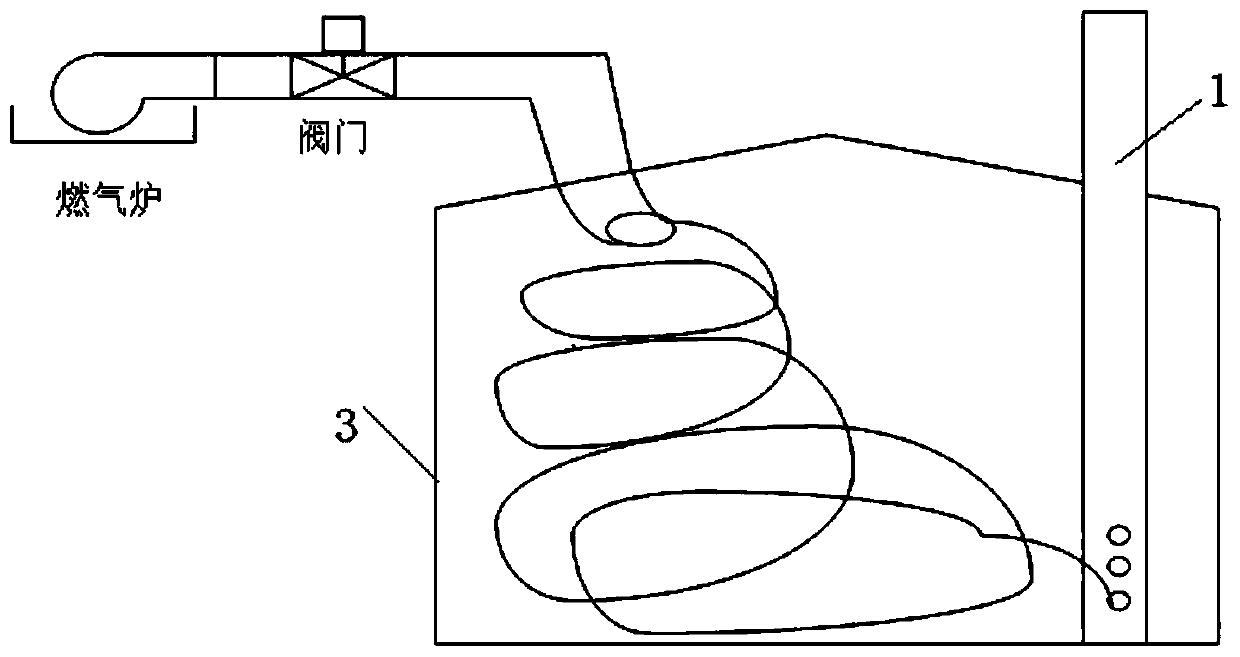

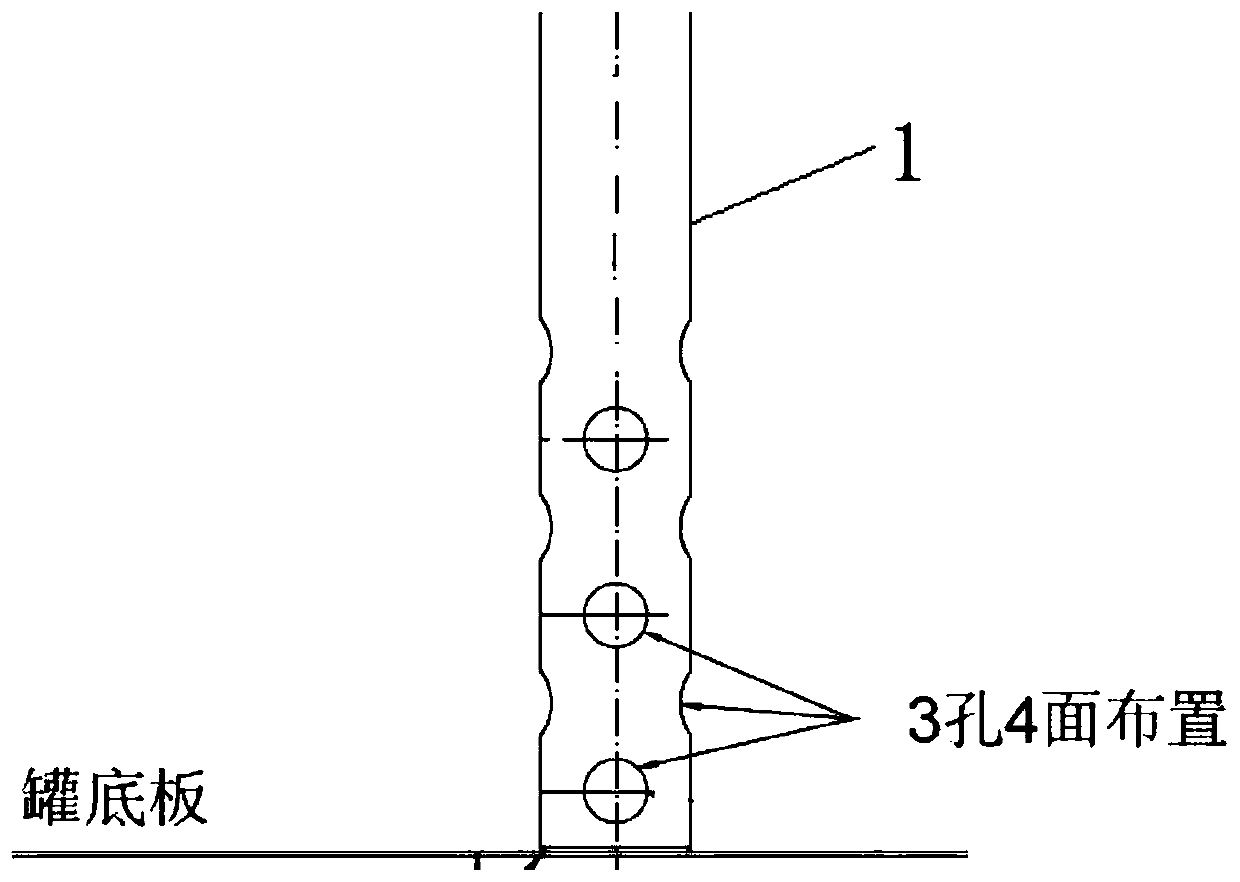

[0036] 1. A pipeline connection is reserved on the top of the molten salt tank 3, and gas furnaces, val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com