A kind of fabric reinforced concrete-steel pipe-frp composite pipe and its manufacturing method

A technology of fabric reinforcement and concrete, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve problems that affect people's daily life, affect the normal use of pipes, increase cracks in composite pipes, etc., and reduce the risk of rupture , light weight, widening the effect of using channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

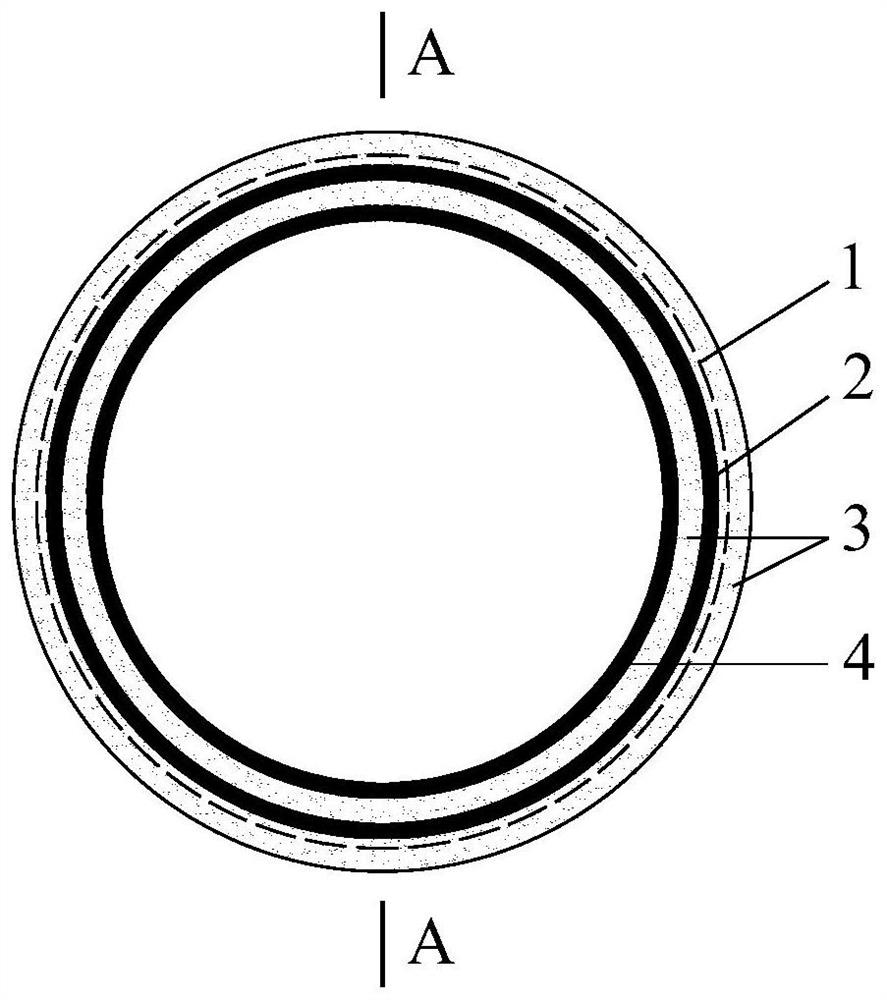

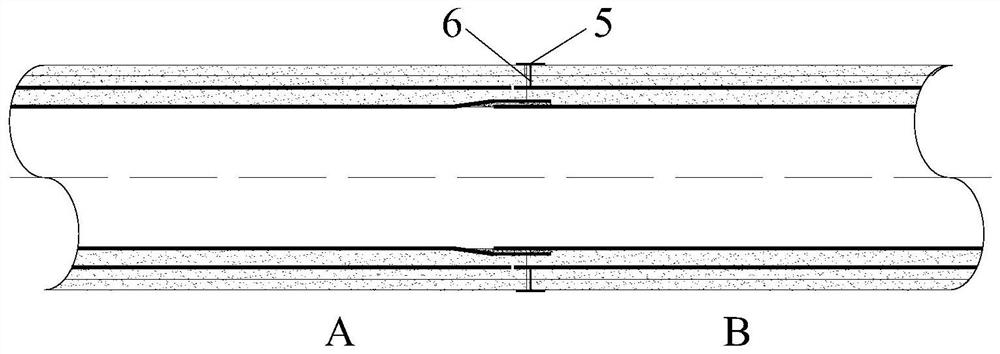

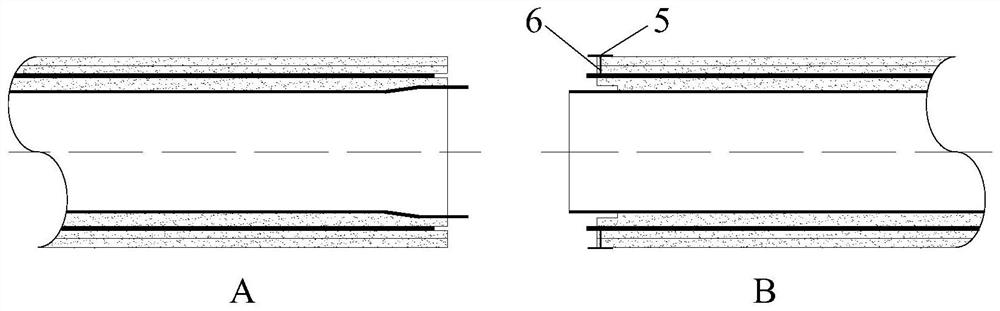

[0033] like Figure 1-3 Shown is a fabric-reinforced concrete-steel pipe-FRP composite pipe, including an FRP round pipe 4 coaxially arranged from inside to outside, a thin-walled steel pipe 2, and fabric-reinforced concrete;

[0034] The FRP round pipe 4 adopts multi-strand continuous fibers to be wound and formed after being treated with resin materials, and the two ends of the FRP round pipe 4 have sockets and sockets respectively; one end of the thin-walled steel pipe 2 is shorter than the FRP round pipe 4, and the other end is longer than the FRP round pipe 4. FRP round pipe 4, and fine-grained concrete 3 is poured between the FRP round pipe 4 and the thin-walled steel pipe 2; the outer surface of the fabric reinforced concrete at the interface is provided with a steel collar 5 through a stud 6, and the steel collar 5 below is provided with sealing rubber gasket....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com