Multi-layer kitchen paper with composite gluing solution

A technology of kitchen paper and sizing solution, which is applied in the field of kitchen paper, can solve the problems of low plant fiber utilization efficiency, low cleaning efficiency, low pulping yield, etc., achieve excellent water repellency, save production costs, and disperse Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] This embodiment provides a composite sizing solution for kitchen paper base paper, which is prepared from the following components in mass percentage:

[0106]

[0107] Wherein said cationic water-based polyurethane-acrylate is epoxy resin modified castor oil-based cationic water-based polyurethane-acrylate,

[0108] The sizing solution strengthening agent is a mixture including pentafluoroethyl substituted pyridine compounds, polysorbate and carboxymethyl cellulose.

[0109] The sizing solution strengthening agent is a mixture of pentafluoroethyl-substituted pyridine compounds, polysorbate and carboxymethyl cellulose shown in formula (1) at a weight ratio of 1:5:24.

[0110] The sizing solution enhancer described in this application uses pentafluoroethyl-substituted pyridine compounds combined with polysorbate and carboxymethyl cellulose to form a joint compatibility enhancer. Oily and film-forming properties, and it is also beneficial to inhibit the growth of fung...

Embodiment 2

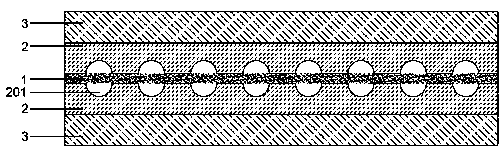

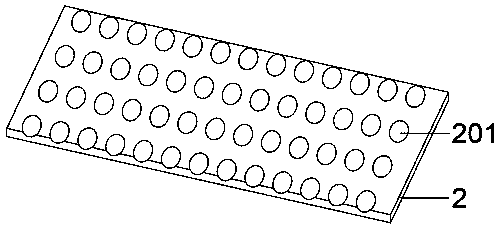

[0163] Embodiment 2 is basically the same as Embodiment 1, except that in Embodiment 2, the hollow layer is present in strips between the lower surface layer and the sizing layer and between the sizing layer and the lower surface layer between.

Embodiment 3

[0165] Embodiment 3 is basically the same as Embodiment 1, except that in Embodiment 3, the hollow layer exists in a belt shape between the lower surface layer and the sizing layer and between the sizing layer and the lower surface layer between.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com