Method for controlling synthesis stability of polyhydroxyalkanoate of mixed flora through sodium chloride

A technology of polyhydroxyalkanoate and mixed flora, applied in the direction of using microorganisms, fermentation, etc., can solve the problems of high input cost, long adjustment cycle, poor operability, etc., to prevent excessive dosing, reduce impact, and relatively Effect of less running loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

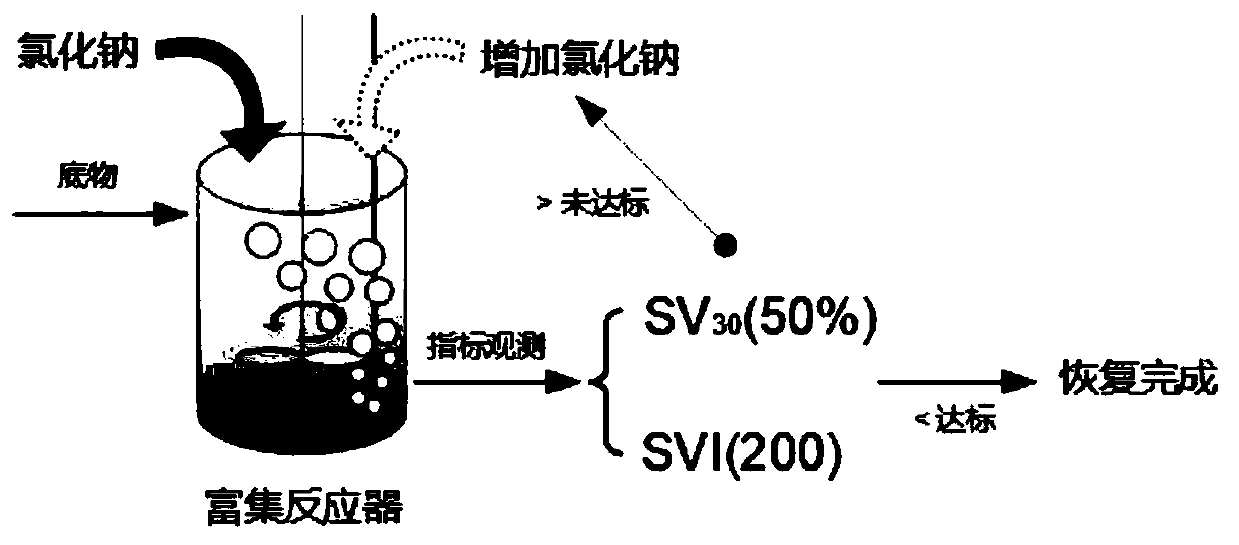

[0023] Specific embodiment one: the sodium chloride of the present embodiment is used for the method for rapid recovery destabilizing polyhydroxyalkanoate mixed flora production process, and concrete steps are as follows:

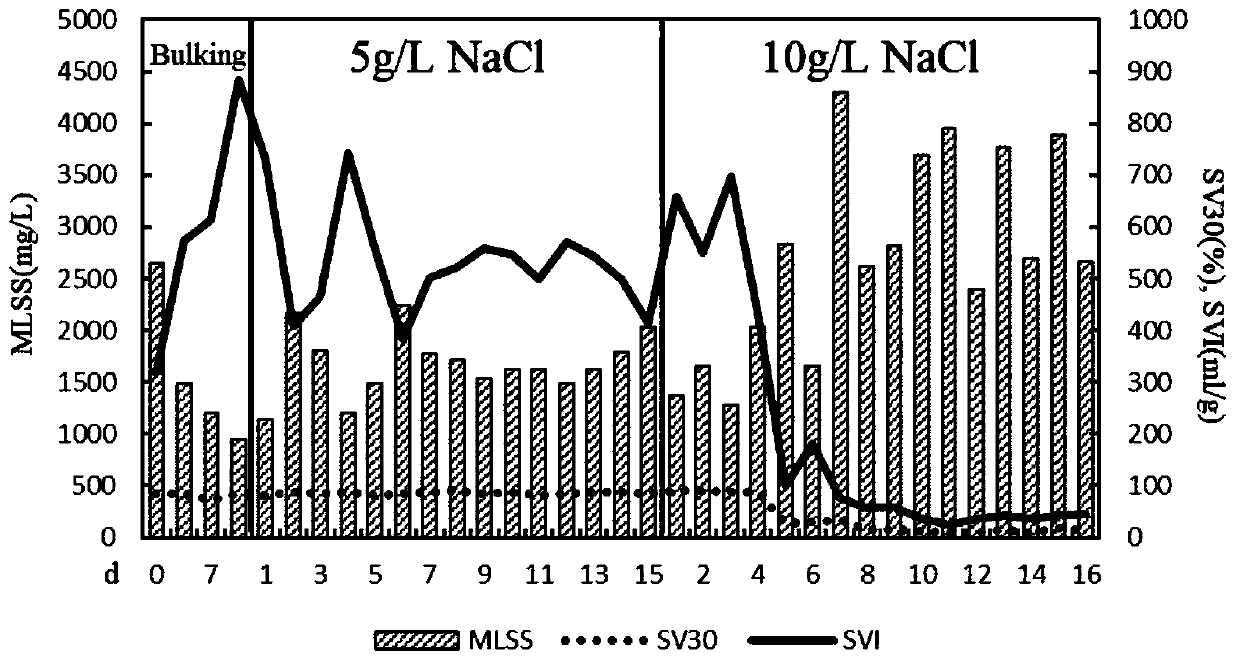

[0024] 1. Add 3-5g / L sodium chloride to the domesticated SBR reactor of PHA mixed flora caused by the expansion of filamentous bacteria to produce sludge loss. The volume load of the SBR reactor is 1000-2000mgCOD / L / d, The substrate carbon source is a combination of acetic acid, propionic acid, butyric acid, valeric acid and ethanol, the SRT is 10d, the HRT is 1d, and the operation cycle is 12h;

[0025] 2. Take 100mL of the mixed solution at the end of the period from the SBR reactor, and observe the daily reactor sludge sedimentation ratio (SV 30 ) and mixed liquor suspended solids concentration (MLSS), calculate the sludge volume index (SVI);

[0026] Three, such as SV 30 Not higher than 50%, SVI not greater than 200, MLSS value not lower than 2500mg / L,...

specific Embodiment approach 2

[0033] Embodiment 2: This embodiment is different from Embodiment 1 in that: the SBR reactor is under the condition of 15-25° C., and the aeration is continued. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the operation period of the SBR reactor is 6-12 hours. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com