PU protective film for OLED film packaging process and preparation method thereof

A technology of thin film encapsulation and protective film, which is applied in the direction of film/sheet release liner, film/sheet adhesive, semiconductor/solid device manufacturing, etc., to achieve no carbonization in screen cutting, improve comprehensive performance, and meet OLED requirements. The effect of process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

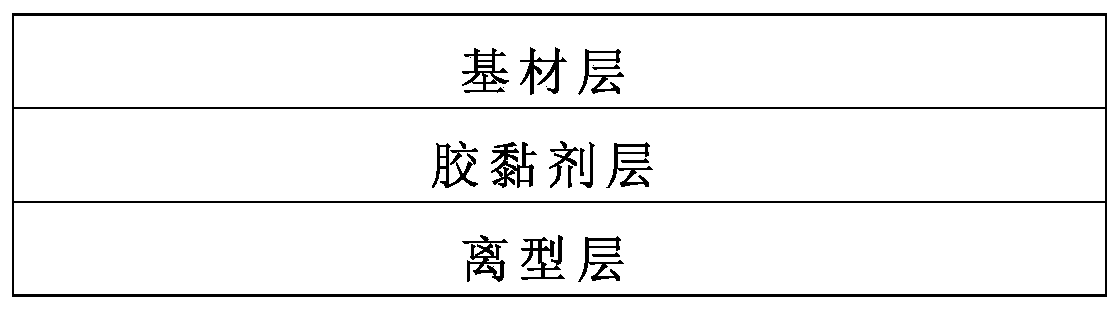

[0045] like figure 1 As shown, this embodiment is a PU protective film, which consists of a substrate layer, an adhesive layer and a release layer from top to bottom. The substrate layer is single-sided antistatic PET with a thickness of 75 μm, the thickness of the adhesive layer is 75 μm, and the release layer is a silicone double-sided antistatic release film with a thickness of 25 μm.

[0046] The preparation method of PU protective film comprises the steps:

[0047] S1: Polyurethane resin preparation: polyether polyol (Dow, model 2000LM), polycarbonate polyol (Ube Chemical, model PH100D), polyester polyol (Asahikawa Chemical, model XCP 1000N) are polymerized, and the quality of the feed The ratio is 20:70:10, the polymerization method refers to the summary of the invention, and ethyl acetate is used to make a masterbatch with a solid content of 70%;

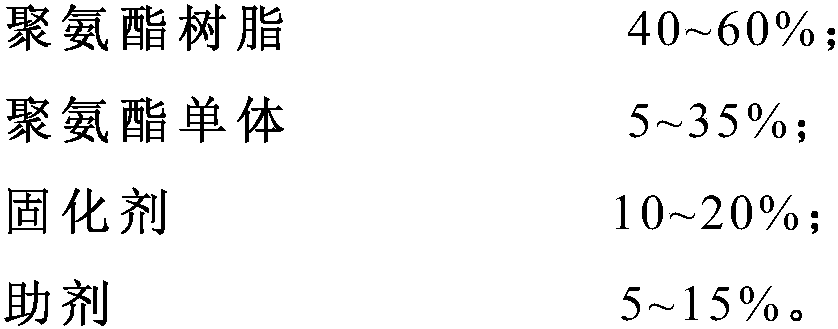

[0048] S2: Take 100g of the masterbatch prepared in step S1, add 40g of polyurethane monomer (polycarbonate polyol, Ube Che...

Embodiment 2

[0051] like figure 1 As shown, this embodiment is a PU protective film, which consists of a substrate layer, an adhesive layer and a release layer from top to bottom. The substrate layer is single-sided antistatic PET with a thickness of 75 μm, the thickness of the adhesive layer is 75 μm, and the release layer is a silicone double-sided antistatic release film with a thickness of 25 μm.

[0052] The preparation method of PU protective film comprises the steps:

[0053] S1: Polyurethane resin preparation: polyether polyol (Dow, model 2000LM), polycarbonate polyol (Ube Chemical, model PH 100D), polyester polyol (Asahikawa Chemical, model XCP1000N) are polymerized, and the quality of the feed The ratio is 20:70:10, the polymerization method refers to the summary of the invention, and ethyl acetate is used to make a masterbatch with a solid content of 70%;

[0054] S2: Take 100g of the masterbatch prepared in step S1, add 40g of polyurethane monomer (polyether polyol, Dow, mode...

Embodiment 3

[0057] like figure 1 As shown, this embodiment is a PU protective film, which consists of a substrate layer, an adhesive layer and a release layer from top to bottom. The substrate layer is single-sided antistatic PET with a thickness of 75 μm, the thickness of the adhesive layer is 75 μm, and the release layer is a silicone double-sided antistatic release film with a thickness of 25 μm.

[0058] The preparation method of PU protective film comprises the steps:

[0059] S1: Polyurethane resin preparation: polyether polyol (Dow, model 2000LM), polycarbonate polyol (Ube Chemical, model PH100D), polyester polyol (Asahikawa Chemical, model XCP 1000N) are polymerized, and the quality of the feed The ratio is 30:60:10, the polymerization method refers to the summary of the invention, and ethyl acetate is used to make a masterbatch with a solid content of 70%;

[0060] S2: Take 100g of the masterbatch prepared in step S1, add 40g of polyurethane monomer (polycarbonate polyol, Shang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com