A kind of humic acid modified viscosity reducer and preparation method thereof

A technology of humic acid and viscosity reducer, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as differences in emulsification performance, achieve the effect of reducing shear stress, wide sources, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

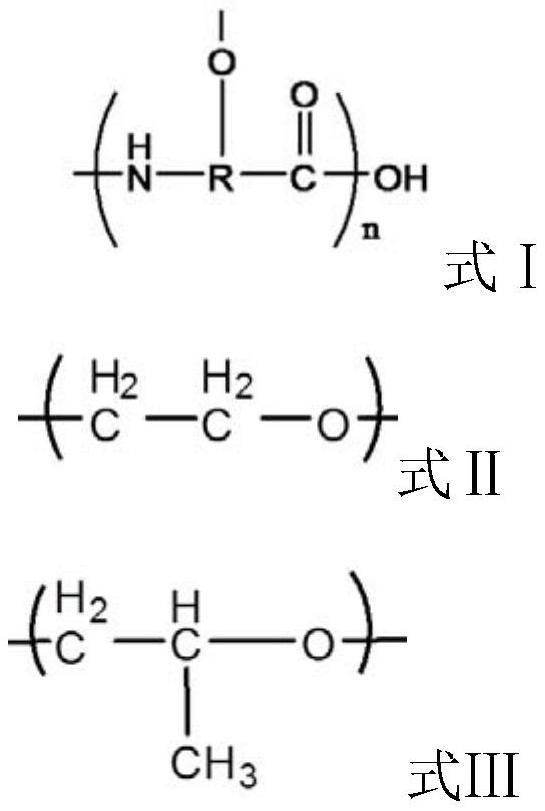

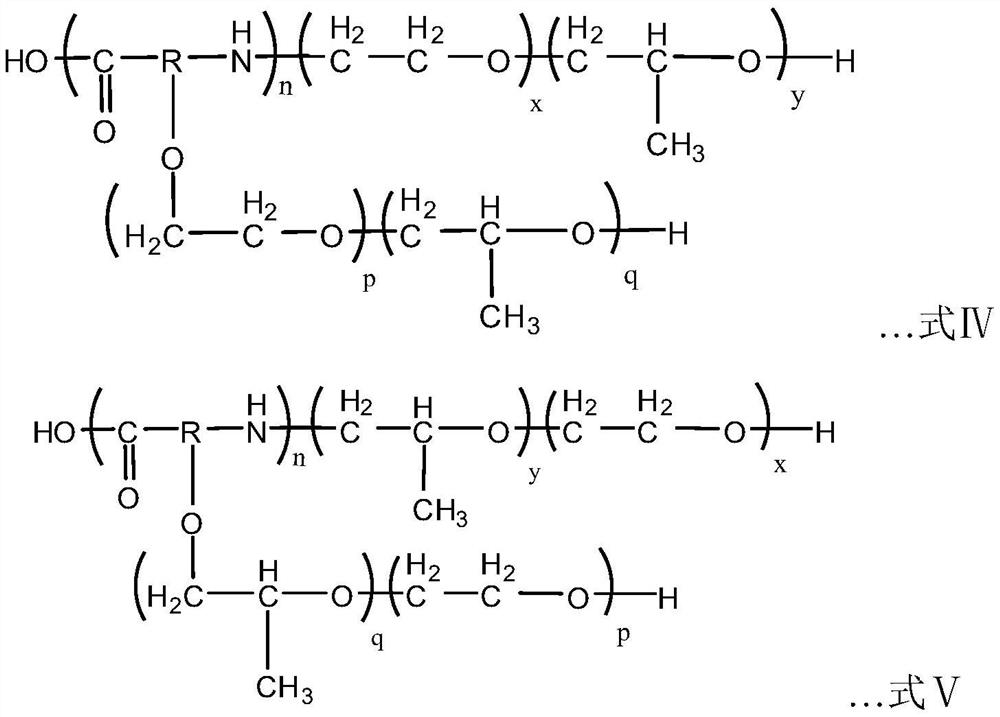

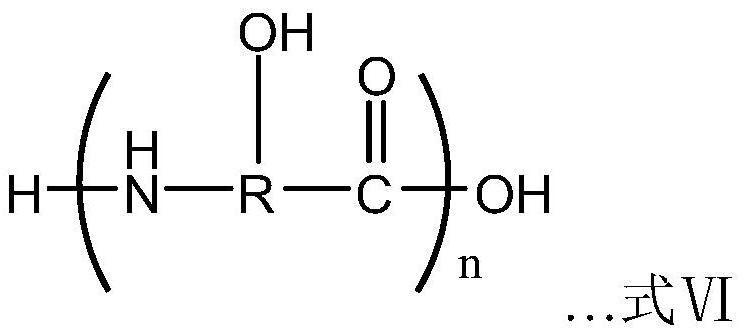

[0037] The synthesis steps of the humic acid modified molecule of the present embodiment are:

[0038] Add humic acid (HA, molecular weight range 600-1000), 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC), 4-dimethylaminopyridine into the reaction vessel (DMAP), anhydrous dichloromethane. The molar ratio is HA:EDC:DMAP=1:1.5:0.15, and the volume ratio is HA:anhydrous dichloromethane=1:14. At 40°C, after 72 hours of reaction, wash and separate phases, and the oil phase part is at 45°C Next, dichloromethane was removed by rotary evaporation to obtain a mixed product (HA) n , the molecular weight range is mainly concentrated in 2500-4000.

[0039] will get (HA) n As a macromolecular initiator, 0.3 g concentration of 6% DMC catalyst suspension was added to 15 g (HA) n , and carry out dehydration at 120°C and a reduced pressure of about 4KPa until the water content is lower than 0.02%. Then, about 1 g of ethylene oxide was metered in and a period of time was ...

Embodiment 2

[0042] The synthesis steps of the humic acid modified molecule of the present embodiment are:

[0043]Add humic acid (HA, molecular weight range 200-400), 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC), 4-dimethylaminopyridine into the reaction vessel (DMAP), anhydrous dichloromethane. The molar ratio is HA:EDC:DMAP=1:1.55:0.15, and the volume ratio is HA:anhydrous dichloromethane=1:16. At 40°C, wash with water and separate phases after reacting for 72 hours, and the oil phase part is at 45°C Next, dichloromethane was removed by rotary evaporation to obtain a mixed product (HA) n , the molecular weight range is mainly concentrated in 4000-6000.

[0044] will get (HA) n As a macromolecular initiator, 0.3 g concentration of 6% DMC catalyst suspension was added to 25 g (HA) n , and carry out dehydration at 120°C and a reduced pressure of about 4KPa until the water content is lower than 0.02%. Then, about 1 g of ethylene oxide was metered in and a period of...

Embodiment 3

[0047] The synthesis steps of the humic acid modified molecule of the present embodiment are:

[0048] Add humic acid (HA, molecular weight range 200-600), 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC), 4-dimethylaminopyridine into the reaction vessel (DMAP), anhydrous dichloromethane. The molar ratio is HA:EDC:DMAP=1:1.4:0.14, and the volume ratio is HA:anhydrous dichloromethane=1:20. At 42°C, wash with water and separate phases after 72 hours of reaction, and the oil phase part is at 45°C Next, dichloromethane was removed by rotary evaporation to obtain a mixed product (HA) n , the molecular weight range is mainly concentrated in 6000-10000.

[0049] will get (HA) n As a macromolecular initiator, 0.3 g concentration of 6% DMC catalyst suspension was added to 40 g (HA) n , and carry out dehydration at 130°C and a reduced pressure of about 4.5KPa until the water content is lower than 0.02%. Then, about 1.9 g of propylene oxide were metered in and a per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com