Preparation method of sodium chlorite sustained-release agent

A technology of sodium chlorite and sustained-release agent, which is applied in the field of preparation of sodium chlorite sustained-release agent, can solve problems such as unsafe, slow release, and difficult chlorine dioxide, and achieve high safety, broad application prospects, Easy to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

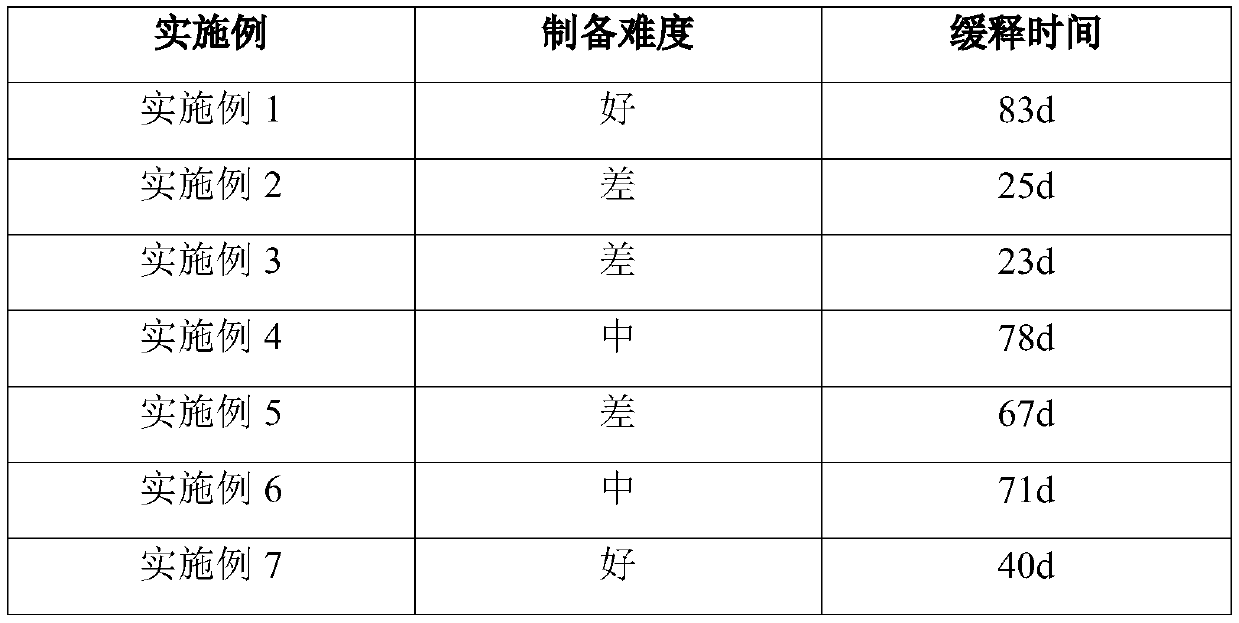

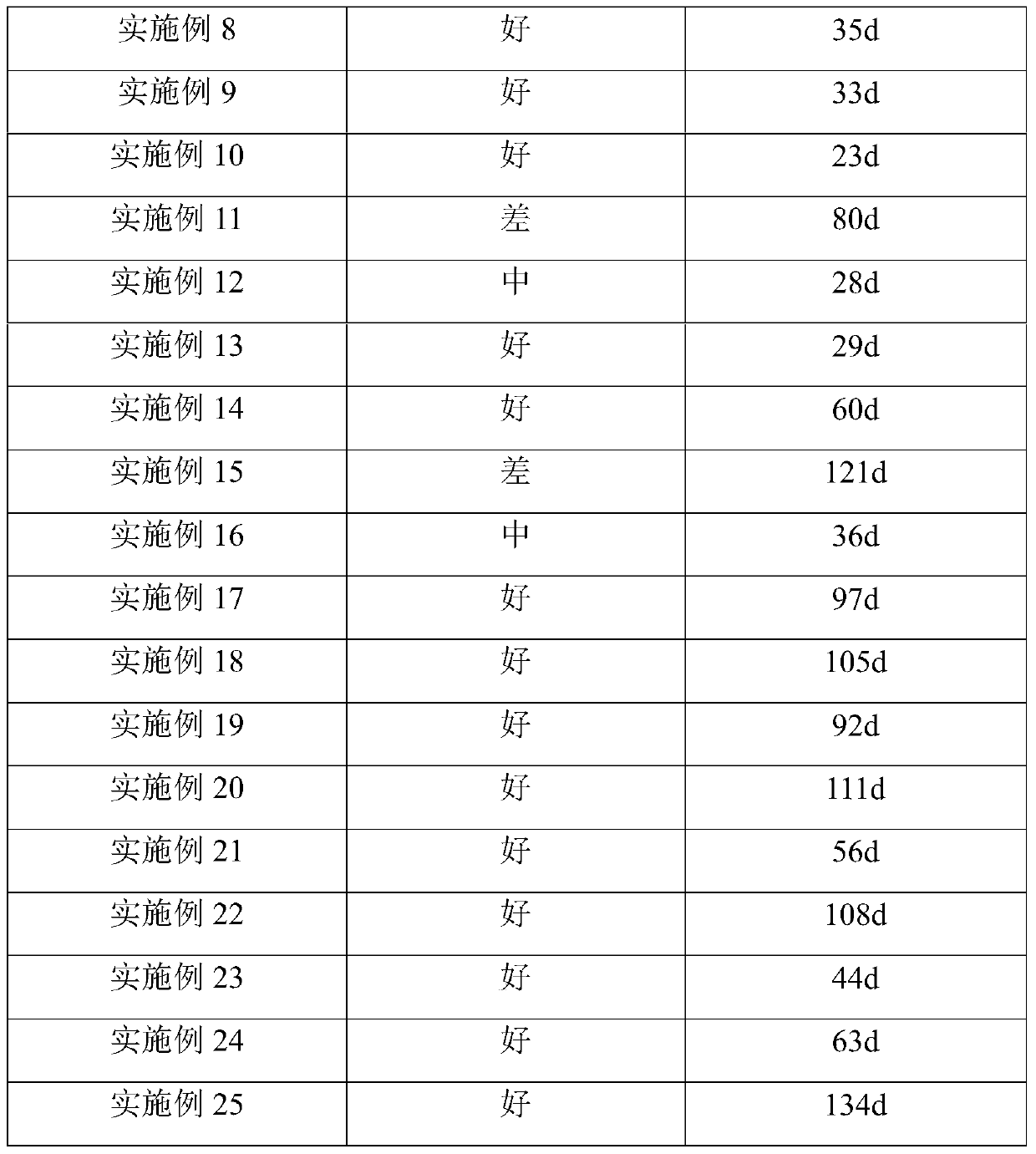

Examples

preparation example Construction

[0018] In order to solve the above problems, the first aspect of the present invention provides a kind of preparation method of sodium chlorite sustained-release agent, comprises the following steps:

[0019] a. take by weighing sodium chlorite, filler, binding agent, mix;

[0020] b. Add water to the mixture obtained in step a, mix evenly, then put it into a pipe, tamp it and solidify it, and you get it.

[0021] In some preferred embodiments, the preparation method of the sodium chlorite sustained-release agent comprises the following steps:

[0022] a. take by weighing sodium chlorite, filler, binding agent, mix;

[0023] b. Continue mixing the mixture obtained in step a under heating conditions, then put it into a tube, tamp it and solidify it, and you get it.

[0024] In some preferred embodiments, the heating temperature in step b is 50-100°C; more preferably, the heating temperature in step b is 55-75°C; furthermore, the heating temperature in step b is The heating t...

Embodiment 1

[0048] Embodiment 1 provides a kind of preparation method of sodium chlorite sustained-release agent, is characterized in that, comprises the following steps:

[0049] a. take by weighing sodium chlorite, filler, binding agent, mix;

[0050] b. Add water to the mixture obtained in step a, mix evenly, then put it into a pipe, tamp it and solidify it, and you get it.

[0051] The ratio of sodium chlorite, filler, binder and water is 1:0.7:0.5:0.1.

[0052] The filler is an inorganic filler; the inorganic filler is quartz powder; the particle size of the quartz powder is 75 microns.

[0053] The binder is calcium sulfate; the calcium sulfate is calcium sulfate hemihydrate.

[0054] In the step b, the diameter of the tube is 20 mm, the length is 100 mm, the two ends are provided with caps, and one cap is provided with 3 small holes with a diameter of 2 mm.

Embodiment 2

[0056] Embodiment 2 provides a kind of preparation method of sodium chlorite sustained-release agent, is characterized in that, comprises the following steps:

[0057] a. take by weighing sodium chlorite, filler, binding agent, mix;

[0058] b. Add water to the mixture obtained in step a, mix evenly, then put it into a pipe, tamp it and solidify it, and you get it.

[0059] The ratio of sodium chlorite, filler, binder and water is 1:0.7:0.5:0.1.

[0060] The filler is an inorganic filler; the inorganic filler is quartz powder; the particle size of the quartz powder is 200 microns.

[0061] The binder is calcium sulfate; the calcium sulfate is calcium sulfate hemihydrate.

[0062] In the step b, the diameter of the tube is 20 mm, the length is 100 mm, the two ends are provided with caps, and one cap is provided with 3 small holes with a diameter of 2 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com