Heat exchange and resistance calculation method for flat fin heat exchanger in air side laminar flow state

A technology of resistance calculation and heat exchanger, applied in calculation, computer-aided design, instrument, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

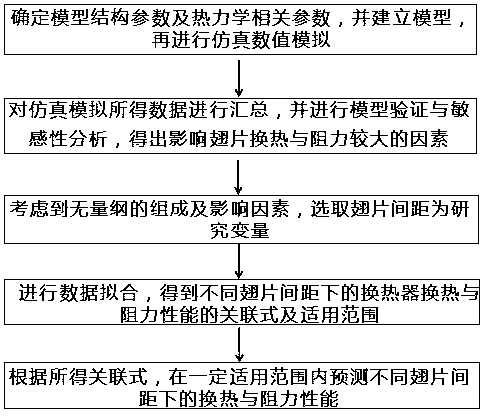

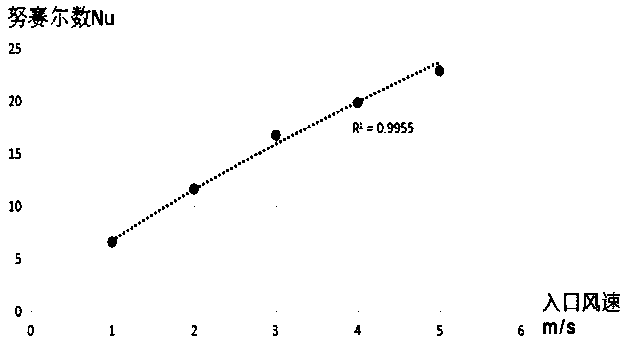

[0034] The present invention proposes a method for calculating heat transfer and resistance of a flat-fin heat exchanger under air-side laminar flow. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be described in detail below in conjunction with specific examples.

[0035] 1. Model structure parameters.

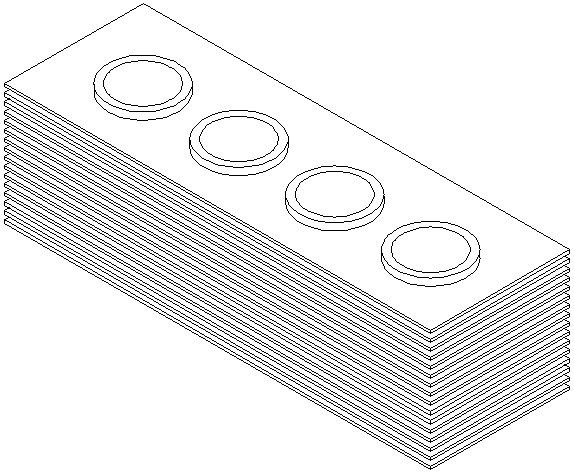

[0036] like figure 1 As shown in the present invention, a heat transfer and resistance calculation method of a flat-fin heat exchanger under the air-side laminar flow state, firstly design the structural parameters of the fin heat exchanger (illustrated with the rated heat transfer of 5.0 kW) , mainly to determine the parameters such as fin spacing, thickness, tube spacing, tube row number, etc. The structural parameters are shown in Table 1:

[0037] Table 1

[0038] Structural parameters Numerical size unit Outer diameter 12.5 mm inner diameter 10 mm wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com