Construction method of large-diameter high-position directional long drilling in double-branch roof

A construction method and large-diameter technology, applied in drilling equipment and methods, earthwork drilling, drilling equipment, etc., can solve the problems of difficulty in controlling the quality of holes, easy passage of holes through layers, and large workload of hole protection. , to avoid channeling phenomenon, shorten the comprehensive hole-forming cycle, and improve the hole-forming quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

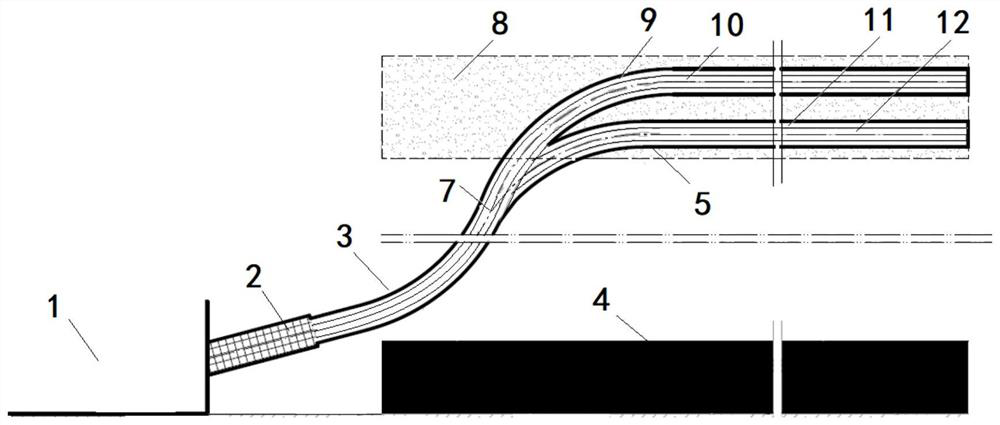

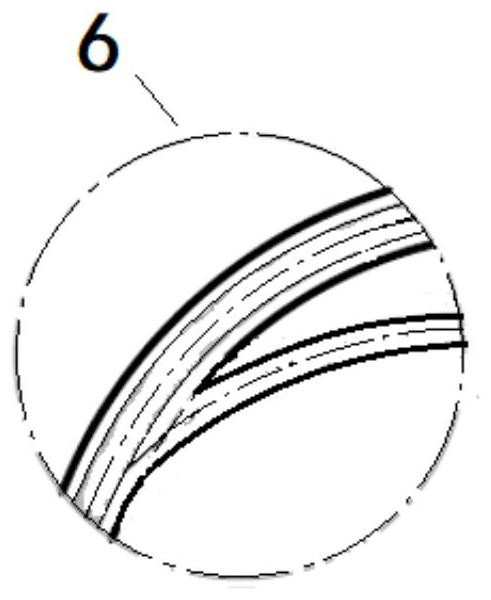

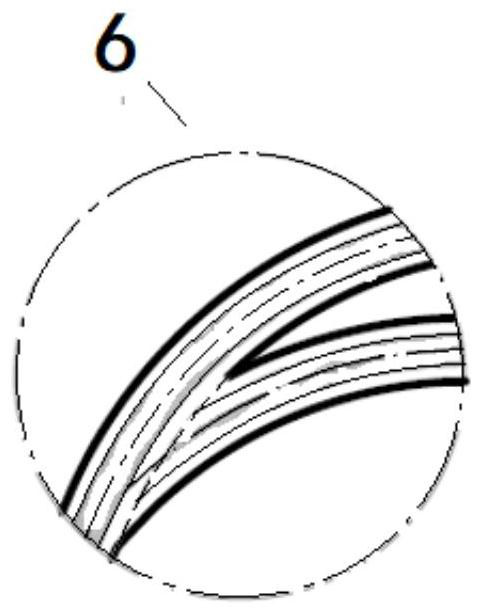

[0034] see figure 1 , Figure 1A with Figure 1B , shows the construction method of the double-branch roof large-diameter high-position directional long drilling of the present invention.

[0035] Wherein, the large-diameter high-position directional long borehole on the double-branch roof is a directional long borehole constructed from the coal seam drilling site 1 to the roof fissure zone 8, which includes the sealing casing section 2, the layer-penetrating hole section 3 and the double-branch drainage The hole section 5 has three parts, the sealing casing section 2 is connected from the coal seam drilling site 1 to one end of the layer-penetrating hole section 3, and the double-branch drainage hole section 5 is located in the roof fracture zone 8 and connected to the layer-piercing hole section 3 the other end, wherein the sealing casing section 2 is designed upward from the coal seam drilling site 1, and the layer-penetrating hole section 3 includes the transition hole s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com