Ammonium nitrogen-free electrolysis releasing agent and application method thereof

A technology without ammonia nitrogen and pendants, applied in the field of metal plating electrolysis, can solve the problems of easy pollution of the environment, difficult treatment of wastewater, a large amount of yellow smoke, etc., and achieve the effects of simple wastewater treatment, reduced pollution, and high stripping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

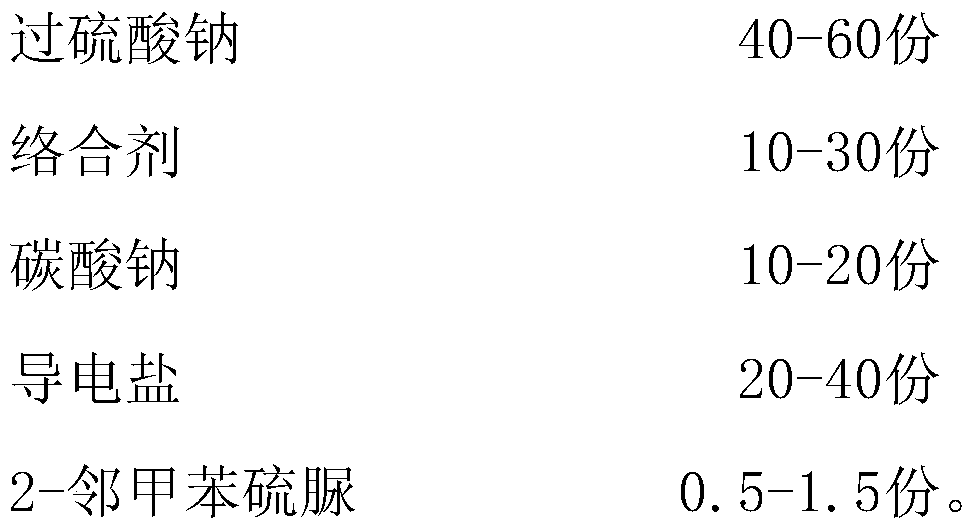

[0024] An ammonia-nitrogen-free electrolysis release agent, which comprises a water solvent and the following raw materials in parts by weight:

[0025]

[0026]

[0027] Specifically, the mass concentration of the electrolytic release agent is 116 g / L. The pH of the electrolytic release agent is 4-6.

[0028] Wherein, the complexing agent is sodium gluconate; the conductive salt is sodium sulfate.

[0029] The preparation method of the electrolytic release agent is as follows: in parts by weight, first add 100 parts of water to the container, and then sequentially add 20 parts of complexing agent, 30 parts of conductive salt, 50 parts of sodium persulfate, 1 part of 2- The o-toluenethiourea and 15 parts of sodium carbonate are stirred and dissolved, and finally water is added until the mass concentration of the solution is 116g / L.

[0030] A method for using an ammonia-nitrogen-free electrolytic stripping agent includes the following steps:

[0031] A. Put the stainless steel pendant...

Embodiment 2

[0035] An ammonia-nitrogen-free electrolysis release agent, which comprises a water solvent and the following raw materials in parts by weight:

[0036]

[0037]

[0038] Wherein, the complexing agent is sodium citrate; the conductive salt is potassium sulfate. The mass concentration of the electrolytic release agent is 80.5 g / L. The pH of the electrolytic release agent is 4.

[0039] The preparation method of the electrolytic release agent is as follows: in parts by weight, first add 100 parts of water to the container, and then sequentially add 10 parts of complexing agent, 20 parts of conductive salt, 40 parts of sodium persulfate, 0.5 parts of 2- The o-toluene thiourea and 10 parts of sodium carbonate are stirred and dissolved, and finally water is added until the mass concentration of the solution is 80.5g / L.

[0040] A method for using an ammonia-nitrogen-free electrolysis release agent, which includes the following steps:

[0041] A. Put the stainless steel pendant to be depl...

Embodiment 3

[0045] An ammonia-nitrogen-free electrolysis release agent, which comprises a water solvent and the following raw materials in parts by weight:

[0046]

[0047]

[0048] The complexing agent is potassium sodium tartrate. The conductive salt is sodium sulfate. The mass concentration of the electrolytic release agent is 151.5 g / L. The pH of the electrolytic stripping agent is 6.

[0049] The preparation method of the above electrolytic release agent is as follows: first add 100 parts of water to the container, and then add 30 parts of complexing agent, 40 parts of conductive salt, 60 parts of sodium persulfate, 1.5 parts of 2-ortho Toluene thiourea and 20 parts of sodium carbonate are stirred and dissolved, and finally water is added until the mass concentration of the solution is 151.5g / L.

[0050] The method of using the above-mentioned ammonia-nitrogen-free electrolysis release agent includes the following steps:

[0051] A. Put the stainless steel pendant to be deplated into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com