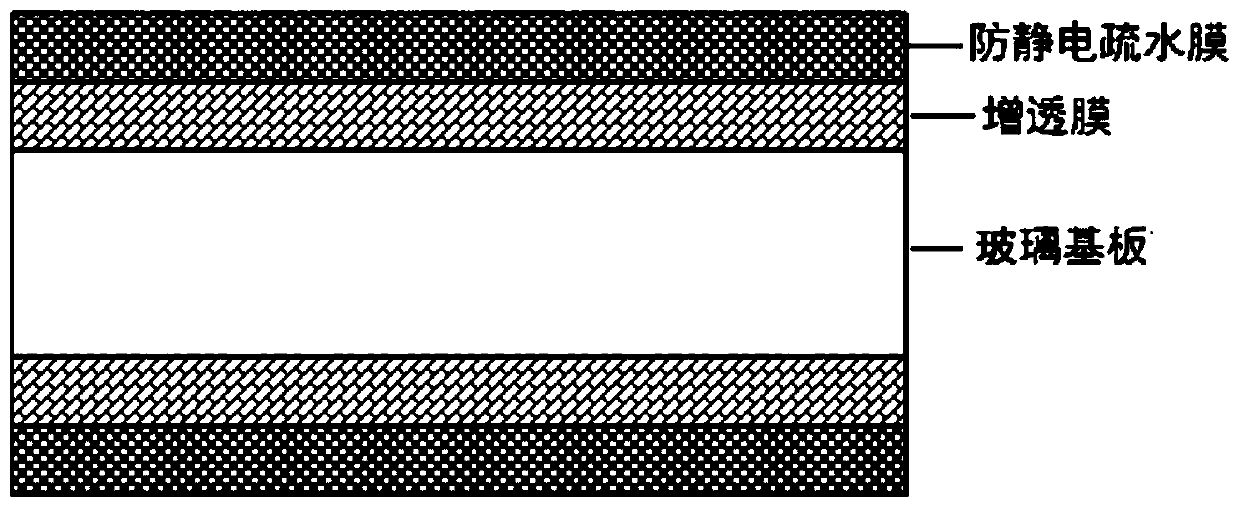

Glass with antistatic, hydrophobic and anti-reflection functions and preparation method of glass

An anti-static, glass technology, applied in the direction of coating, etc., can solve the problems of reducing the overall anti-static property of the glass, light transmittance, easy to produce water stains, complex process, etc., to promote the formation of the glass surface, strengthen the self-cleaning ability, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Preparation of anti-reflection sol: Mix 86.5mL of absolute ethanol, 10.2mL of tetraethyl orthosilicate, and 3.3mL of deionized water, adjust the pH of the mixture to 4 with dilute hydrochloric acid, then add 0.1mL of formamide, and The resulting mixture was heated to 40° C. and kept under magnetic stirring for 4 h, and finally cooled down to room temperature and left to age for 24 h for later use.

[0027] (2) Preparation of antistatic hydrophobic sol: Mix 86.5mL of absolute ethanol, 10.2mL of tetraethyl orthosilicate, and 3.3mL of deionized water, adjust the pH of the solution to 4 with dilute hydrochloric acid, heat the resulting mixture to 40°C and Keep warm and magnetically stir for 4 hours, and finally cool down to room temperature and let stand for 24 hours to obtain silica sol. Add 25.9mL conductive agent dropwise to the silica sol, and the dropping process lasts about 1h. After the conductive agent was added dropwise, 3 mL of hexamethyldisilazane was added ...

Embodiment 2

[0032] This embodiment is basically the same as Example 1, except that the amount of hexamethyldisilazane in step (2) is 4mL, and the glass used in step (c) is ordinary building glass, which is antistatic and hydrophobic After the film is formed, it is also necessary to soak the glass in a 15% (mass fraction) HMDS ethanol solution for 24 hours.

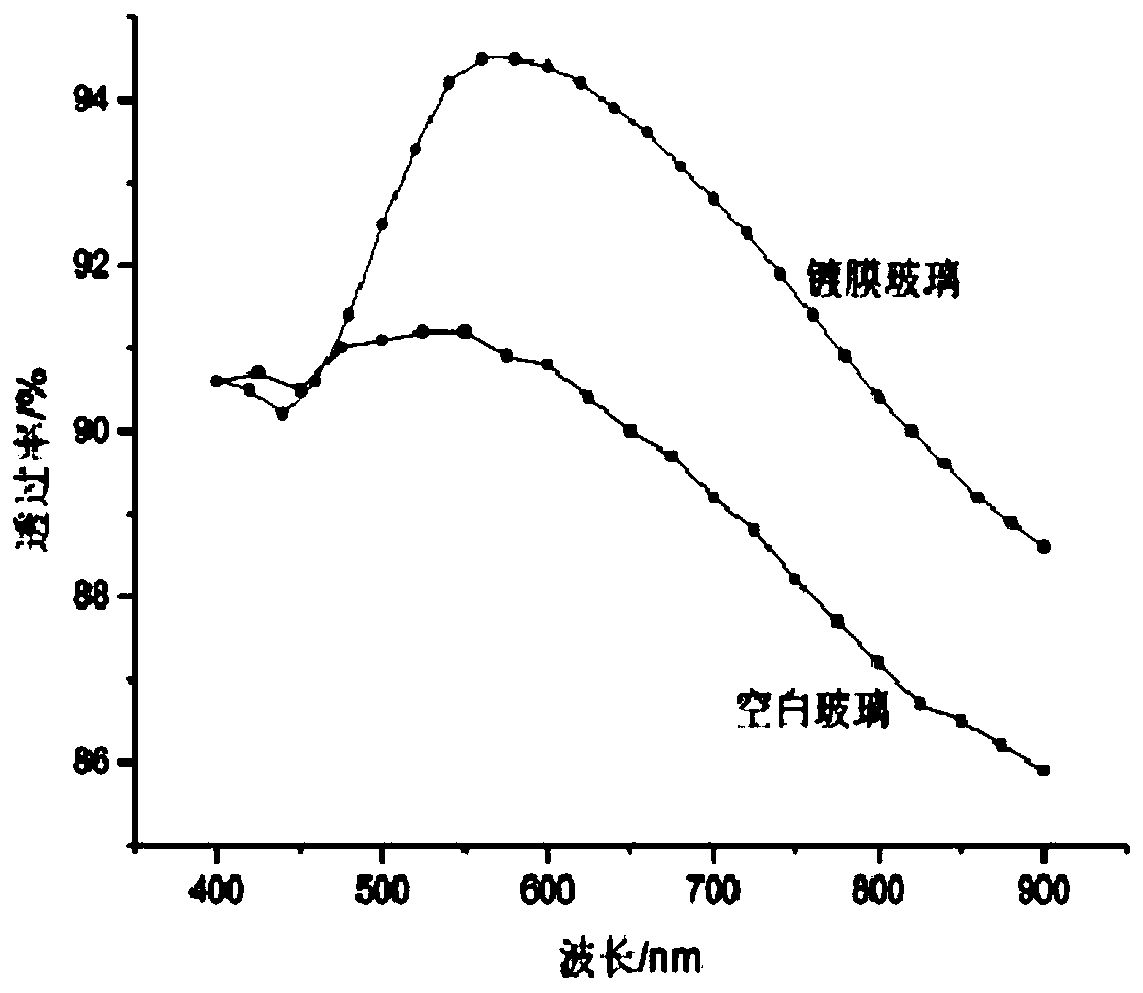

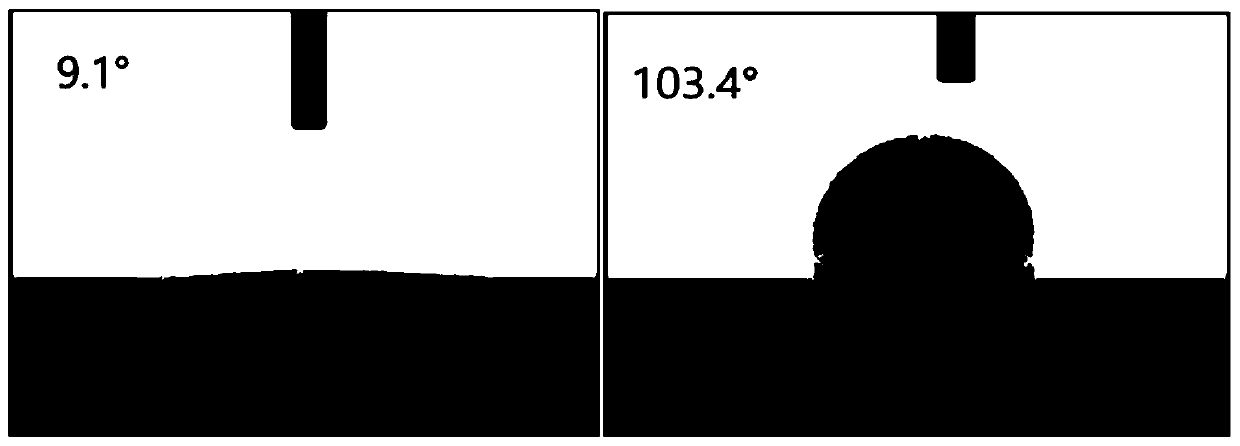

[0033] The double-coated glass and blank glass that embodiment 2 is made have carried out contact angle test respectively, and the result is as follows image 3 shown. image 3 It shows that the surface of the blank glass is hydrophilic, and the contact angle of the glass after coating the double-layer film increases (by 94.3°), indicating that the double-layer film does endow the glass with better hydrophobicity. The friction resistance test was carried out on the glass at room temperature, and the film on the surface was repeatedly wiped with alcohol. After 1000 times of wiping, the average transmittance of the film under light wit...

Embodiment 3

[0035] This example is basically the same as Example 1, except that the amount of conductive agent in step (2) is 30.2mL, the amount of hexamethyldisilazane is 3.3mL, and the glass used in step (c) Glass for outdoor LED display. The test results show that the double-coated glass has the same or similar antistatic, hydrophobic, and high transmittance properties as those of Examples 1 and 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com