Floating ball packing system for sewage treatment and production method

A technology of sewage treatment and floating balls, which is applied in the field of packing system, can solve the problems of easy damage, easy corrosion, aging installation, troublesome and other problems, and achieve the effect of not easy to corrode and simple installation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

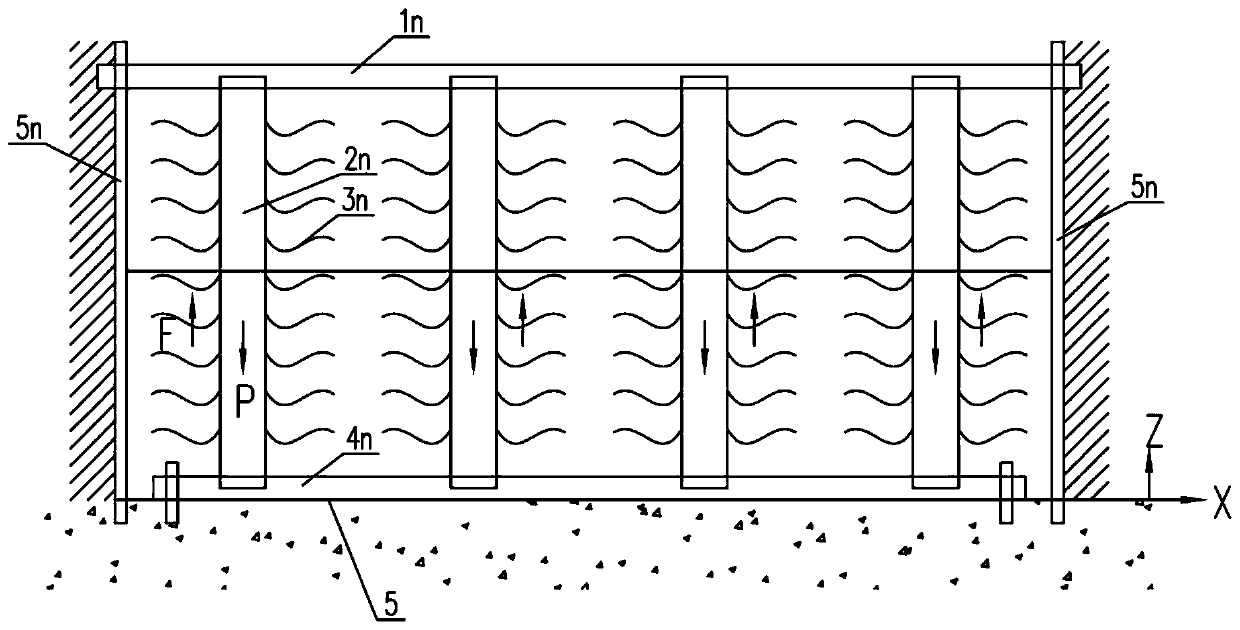

[0022] The floating ball packing system used for the sewage treatment of the present embodiment is composed as follows:

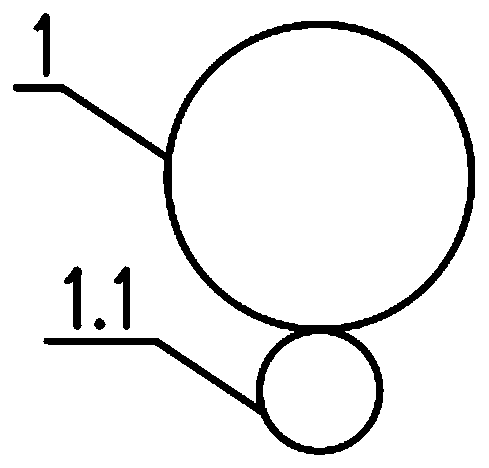

[0023] 1) see figure 2 , the overall layout: a number of evenly distributed floating ball packing bodies are buried in the sewage of the sewage pool, and the components connected in sequence from top to bottom of each floating ball packing body are: floating ball 1, which is covered with packing 3 The lanyard 2, counterweight 4.

[0024] 2) see figure 2 , Floating ball structure: Floating ball 1 is a hollow sphere made of PVC plastic, the lower end of the sphere is fixed with a floating ball hanging ring 1.1, the hanging rope 2 is made of polypropylene rope, and the upper end 2.1 of the hanging rope is fixed on the sphere by knotting Hanging ring 1.1 on. The knot at this place is shown in reference numeral 2a. Floating ball diameter D1 is selected as 10cm.

[0025] 3) see figure 2 The filler 3 is made of aldehyde fiber or polyester filament pressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com