Retractable belt machine

A telescopic belt conveyor, belt technology, applied in the direction of conveyor, transportation and packaging, can solve the problems of untimely evacuation, long waiting time for conveyor line evacuation, inconvenient turning, etc., to ensure stability, ensure sliding smoothness, Easy to disassemble and replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

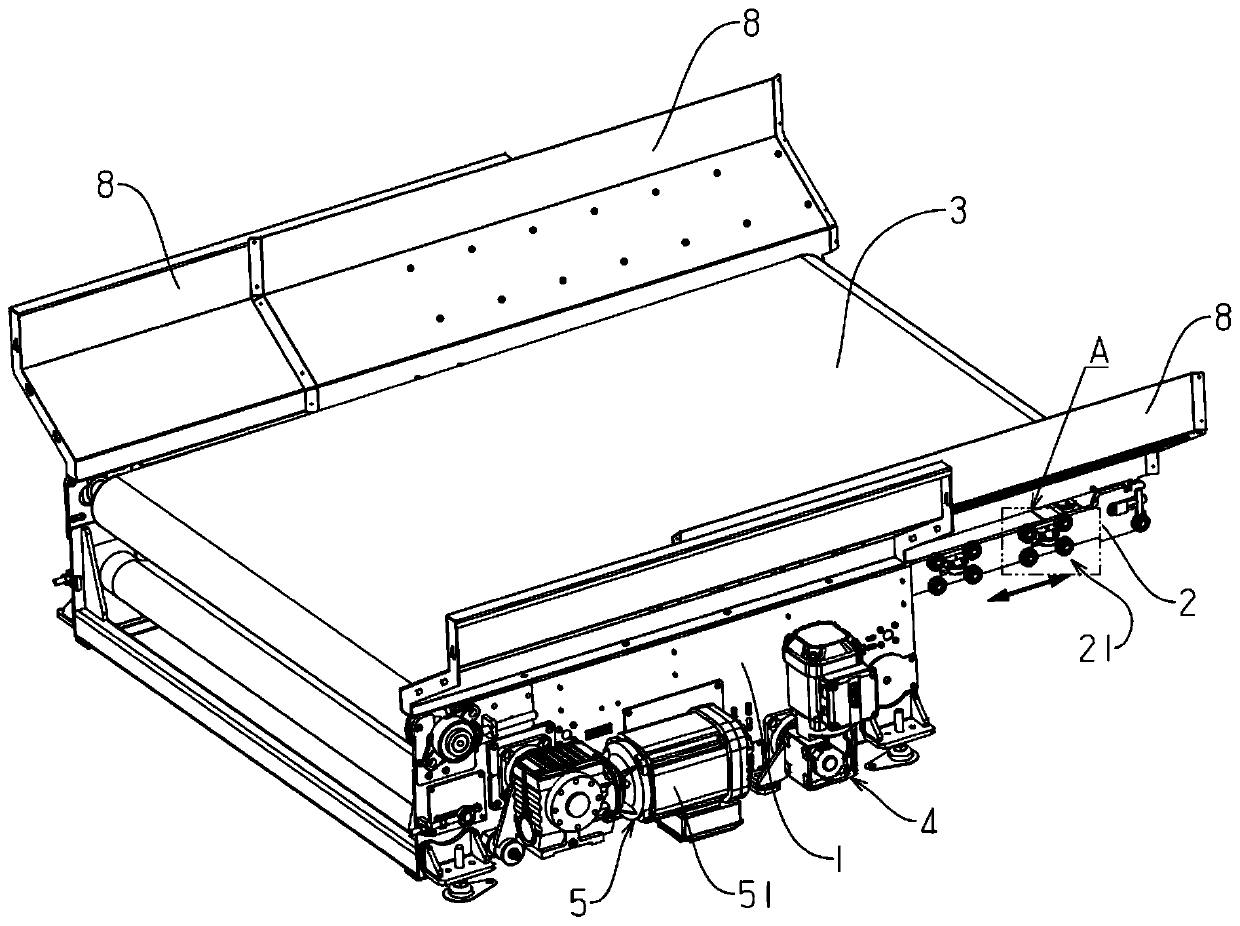

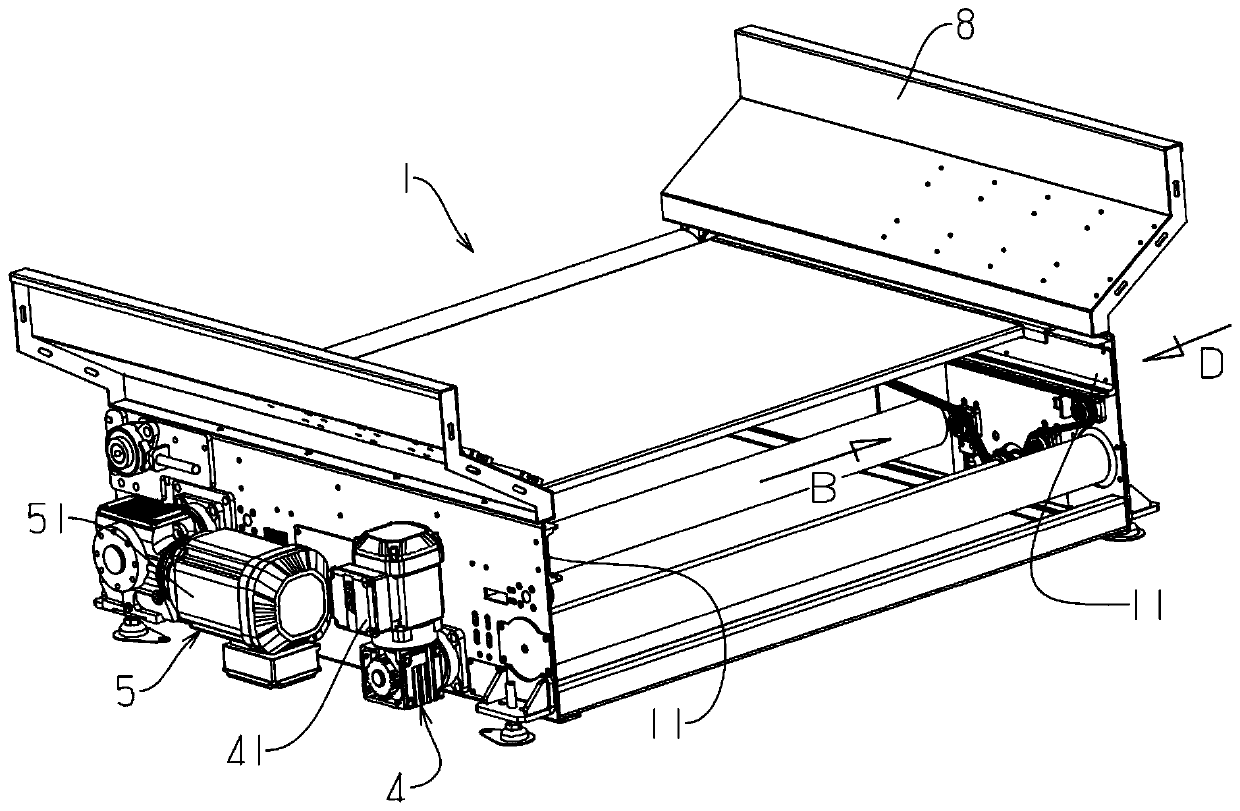

[0040] Embodiment: a kind of telescopic belt machine, as figure 1 and figure 2 As shown: including machine base 1, telescopic frame 2, conveyor belt 3, telescopic drive mechanism 4 and belt drive mechanism 5, the telescopic frame is slidably connected to the machine base, the telescopic drive mechanism is installed on the machine base, Driven by the telescopic drive mechanism, the sliding frame can be extended and retracted along the transmission direction of the conveyor belt, and the conveyor belt is tensioned on the base and the telescopic frame at the same time, through the belt drive mechanism drive the conveyor belt to move;

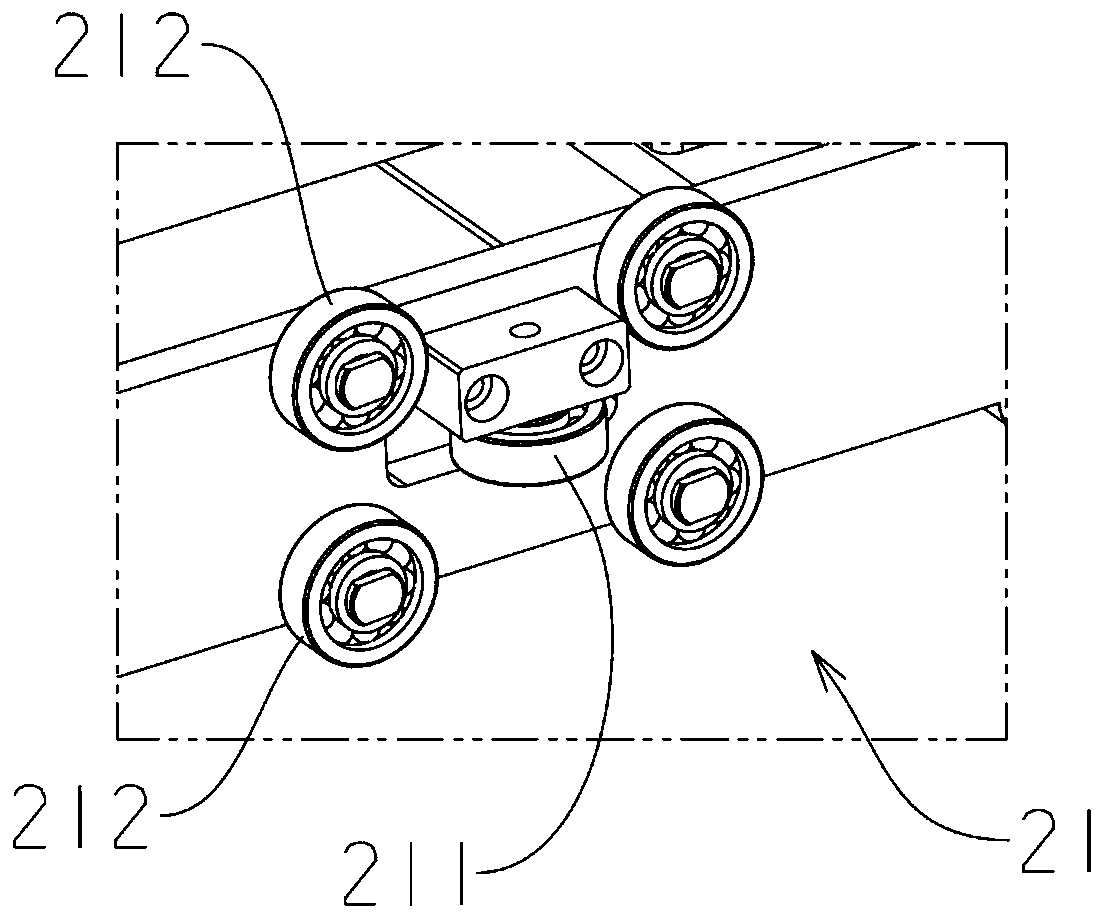

[0041] Both sides of the telescopic frame are provided with some guide wheel sets 21, and the base is provided with guide rails 11 for accommodating the guide wheel sets, the guide wheel sets are installed in the guide tracks, and the guide wheels The wheel set can slide along the guide track, such as image 3 Shown: each set of said guide whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com