A casting method for improving the mechanical properties of large-size aluminum alloy wheels

An aluminum alloy, large-size technology, applied in the field of aluminum alloy casting, can solve problems such as insufficient feeding, achieve the effect of improving feeding capacity, improving feeding efficiency, and ensuring sequential solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: A casting method for improving the mechanical properties of large-sized aluminum alloy automobile wheels

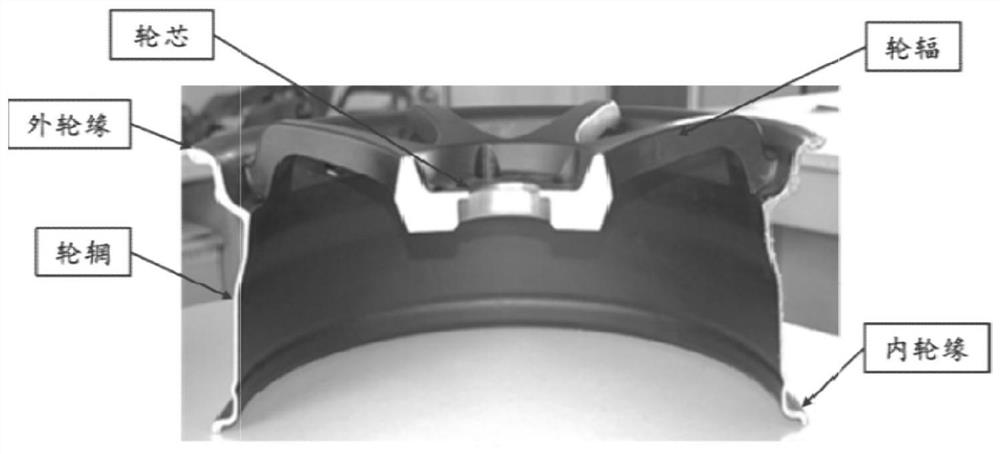

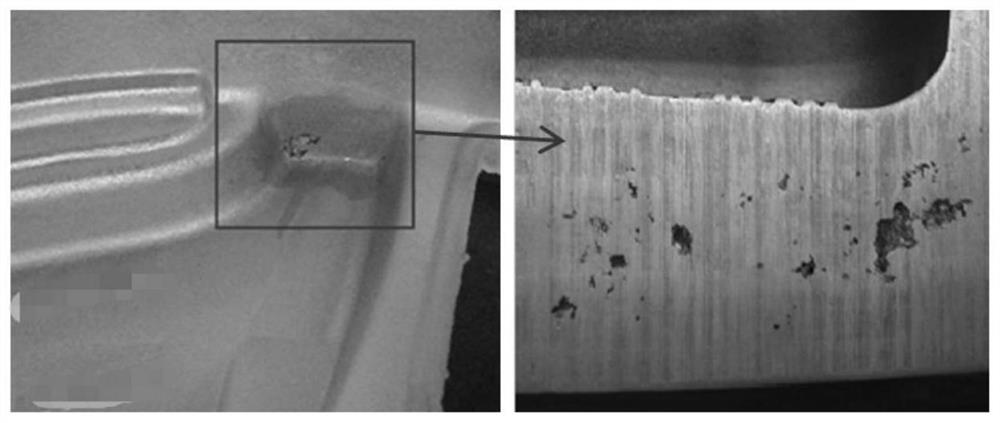

[0035] The implementation object is a 20-inch automobile wheel, the material is A356.2 alloy, and the composition range is shown in Table 1. Common defects in the production of this wheel by conventional low-pressure casting are spoke defects and "R" corner defects. The spoke defects are mainly due to the thin wall thickness of the spokes of this type of wheel. When the temperature field of the mold is not controlled properly, the thin areas of the spokes will solidify first, and the center of the thin areas will solidify later due to the lack of aluminum liquid feed shrinkage and porosity. . The "R" corner defect mainly occurs at the junction of the spoke and the rim, where the thermal joint is thick and is the area where the thickness of the casting transitions, and this part often forms shrinkage cavity defects due to lack of feeding.

[0036] Table...

Embodiment 2

[0053] Example 2: A casting method for improving the mechanical properties of large-size aluminum alloy automobile wheels

[0054] The implementation object is a 20-inch automobile wheel, the material is A356.2 alloy, and the composition range is shown in Table 1. Common defects in the production of this type of wheel by traditional low-pressure casting are similar to those in Example 1, mainly wheel spoke defects and "R" corner defects.

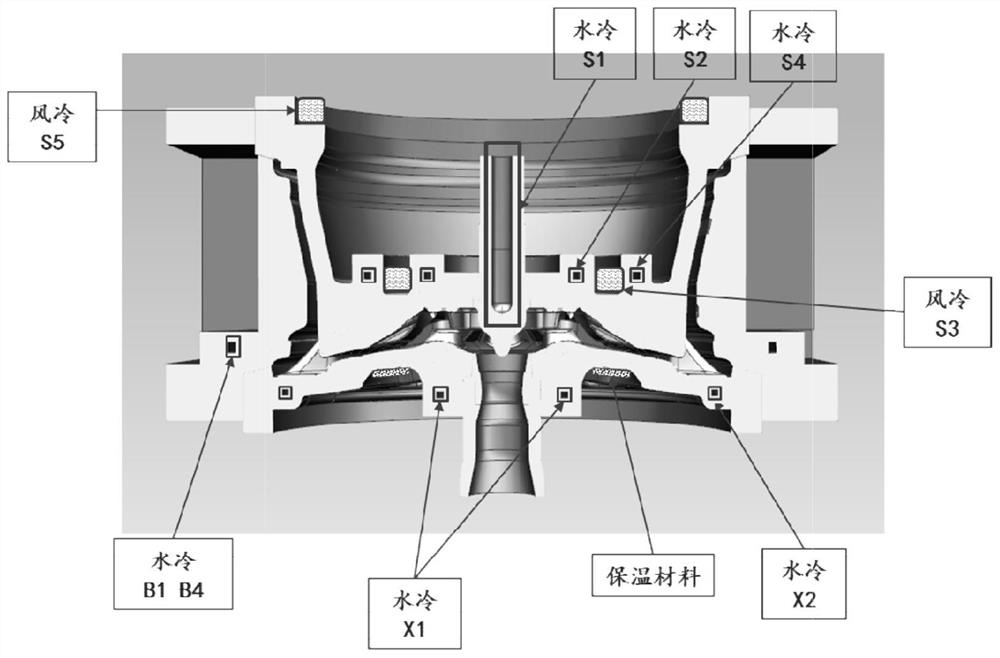

[0055] According to the method of the present invention, the wheel described in embodiment 2 is trial-manufactured, and the cooling layout of the wheel mold is shown in the appendix image 3 As shown, the specific usage is as follows:

[0056] Pre-treatment: A356.2 aluminum ingots are melted, refined (refined and deteriorated), degassed, the composition of the molten aluminum meets the range in Table 1, and the density is 2.61g / cm 3 ; After the mold is sandblasted and sprayed with paint, it is heated to 365°C and then put on the machine. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com