Screening system and screening method for reactive metal powder

A technology for active metal and powder, applied in the field of metal powder screening system, can solve the problems of low screening efficiency and screening accuracy, cumbersome screening process, etc., to improve screening efficiency and screening accuracy, screening The process is simple and the effect of solving the cumbersome screening process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

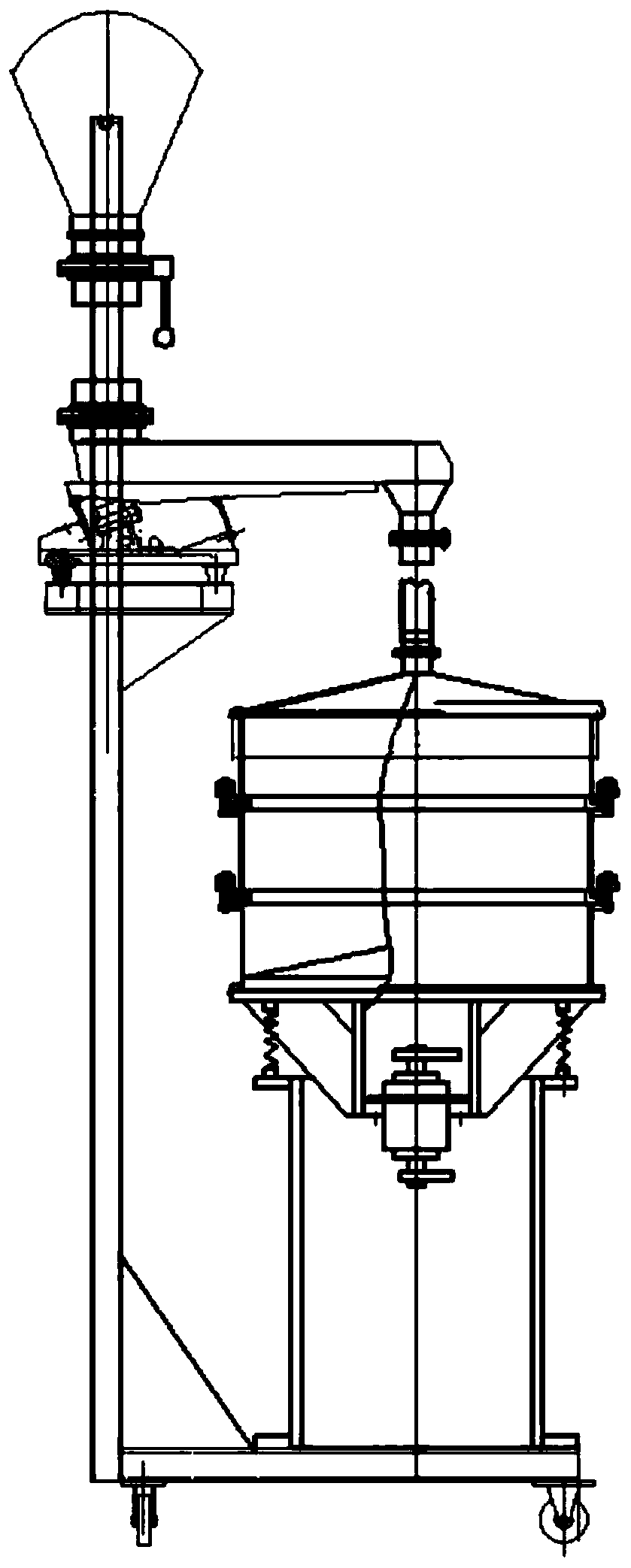

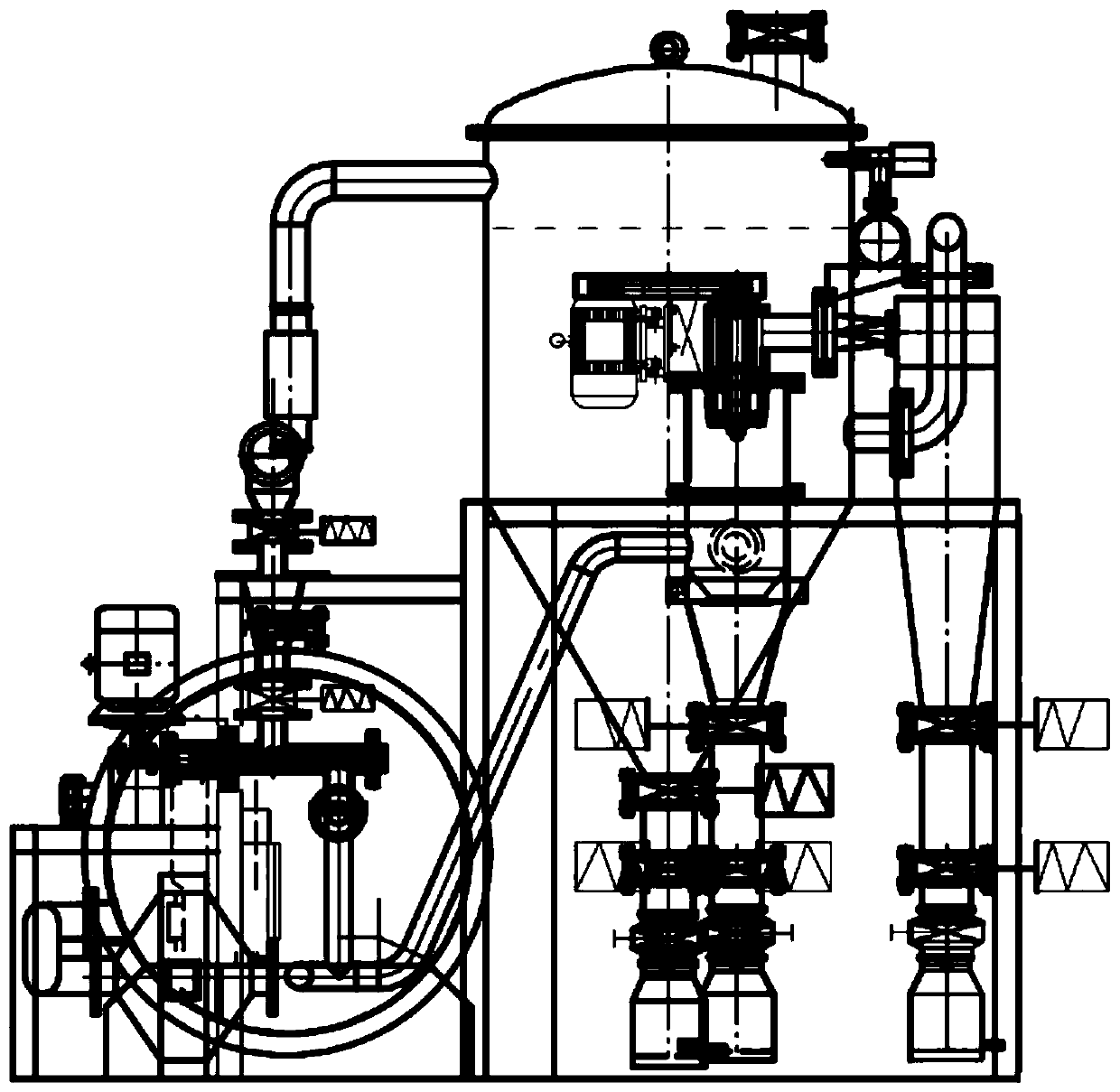

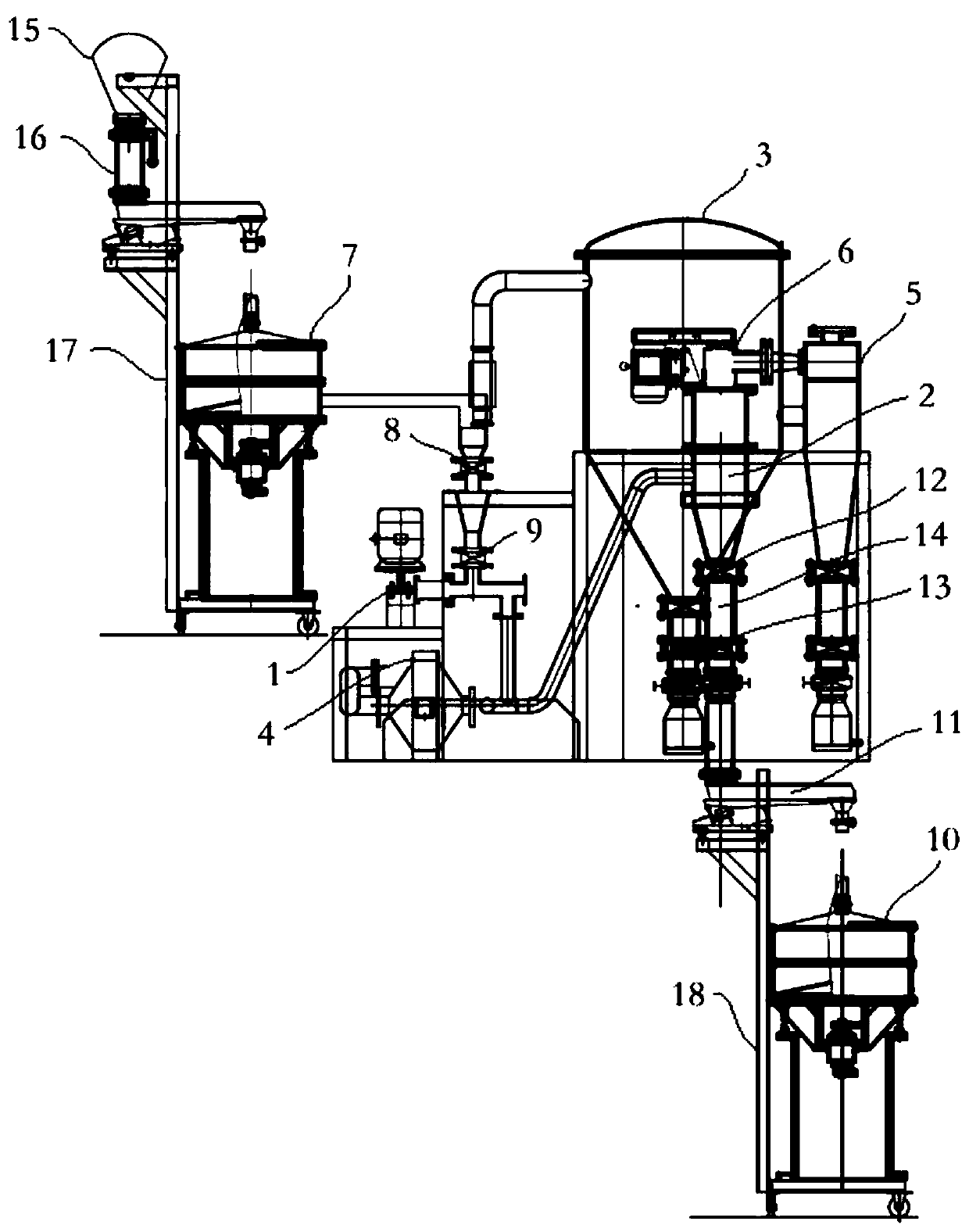

[0079] (1) The original titanium alloy TC4 powder is packed in the powder storage device, and the powder storage device is placed upside down on the first sieving frame, and the inversion height is 0.5 meters away from the feeding port of the first vibrating screen;

[0080] (2) Turn on the protective gas circulation system;

[0081] (3) The discharge port of the powder storage device is connected to the feed port of the first feeder, and the above-mentioned powder is input into the first vibrating screen at a constant speed by the first feeder, and the first vibrating screen is an ultrasonic vibrating screen;

[0082] (4) The screen mesh number on the first vibrating screen is set to be 60 mesh, which is used to remove the bulk metal slag in the TC4 powder, so as to prevent the bulk metal slag from jamming the feeding device during the feeding process, causing heat damage, Then turn on the first vibrating screen. The power of the motor on the first vibrating screen is 500W, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com