A tubular oil container grease scraping device

A technology for oil and grease, applied in the field of tubular oil-containing grease scraping structure, can solve the problem of limited grease collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

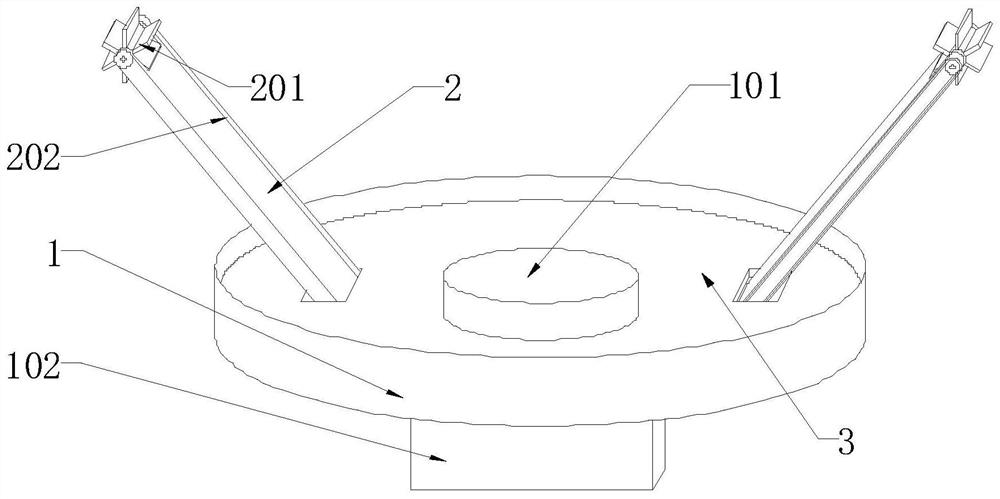

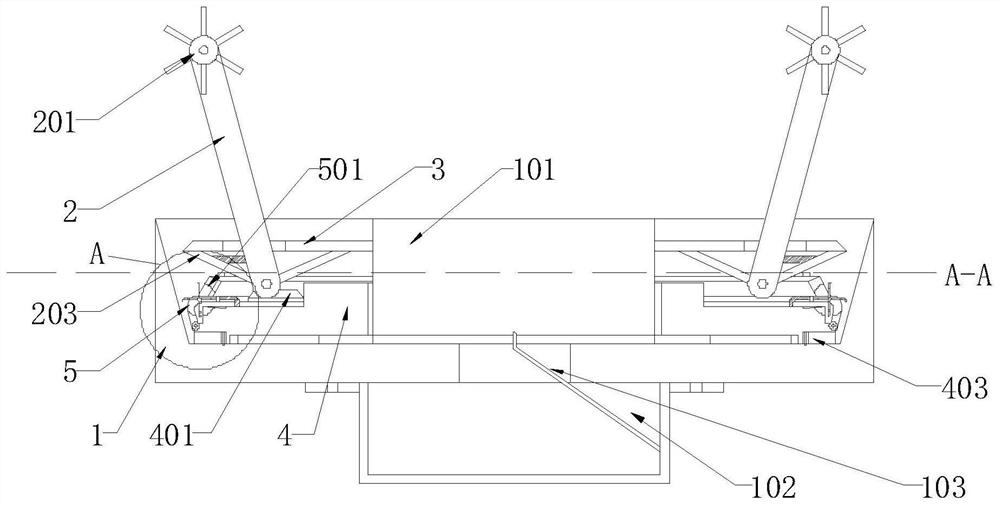

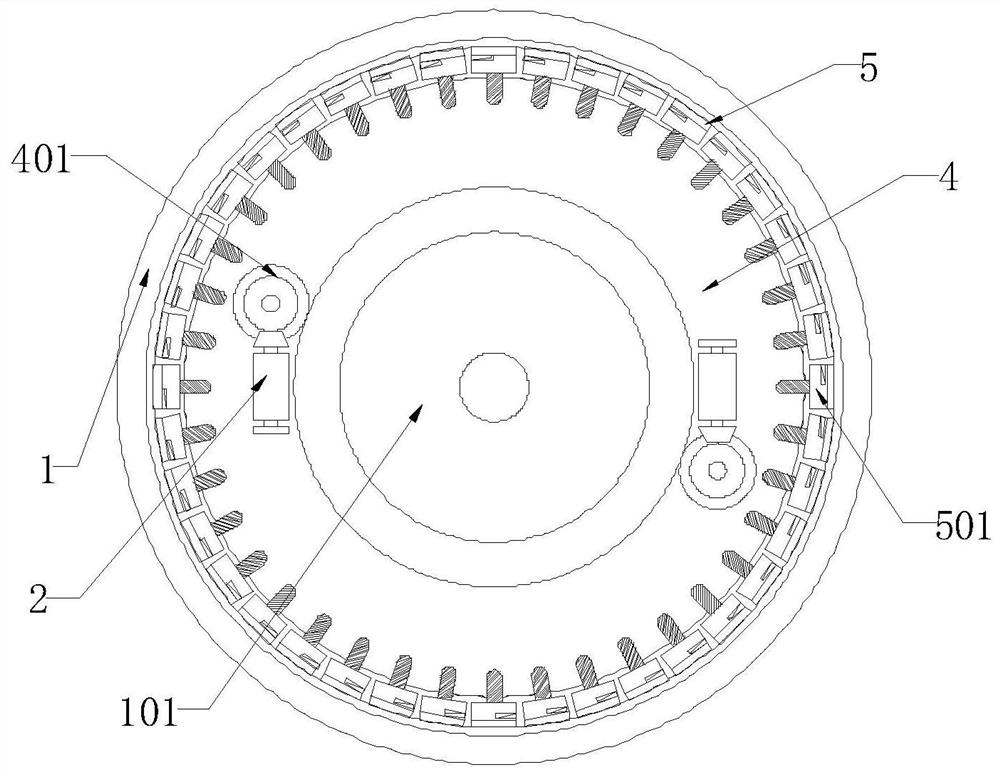

[0031]As attachedfigure 1 AttachedPicture 10 Shown:

[0032]The present invention provides a tubular oil-containing grease scraping device, which includes: oil scraper plate 1, fixed shaft 101, oil hopper 102, oil scraper rod 103, extension rod 2, push wheel 201, chain 202, and connecting rod 203 , The top baffle 3, the push rod 301, the turntable 4, the linkage bevel gear 401, the oil sump, the material transfer sloping plate 403, the oil pressure plate 5, the push plate 501 and the oil grab frame 502, the oil scraper 1 is provided with The fixed shaft 101 is provided with an oil hopper 102 on one side of the oil scraper plate 1, an oil scraper rod 103 is fixedly provided on the inner wall of the oil scraper plate 1, an extension rod 2 is provided on the outer periphery of the fixed shaft 101, and one end of the extension rod 2 is provided with Push wheel 201, a chain 202 is provided on one side of the push wheel 201, a connecting rod 203 is fixedly provided at both ends of the extens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com