Construction Method of Prestressed Tendons in Continuous Rigid Frame Bridges

A technology of prestressed tendons and construction methods, which is applied to bridges, bridge construction, bridge materials, etc., can solve the problems of high resistance at the head of steel beams and insufficient smoothness of beam penetration, and achieve smooth beam penetration, reduced resistance, and smooth penetration of steel beams. beam smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment is applicable to the steel bundle length within 50m.

[0037] The continuous rigid frame bridge prestressed tendon construction method of the present embodiment comprises the following steps:

[0038] Step A. Preparation before wearing:

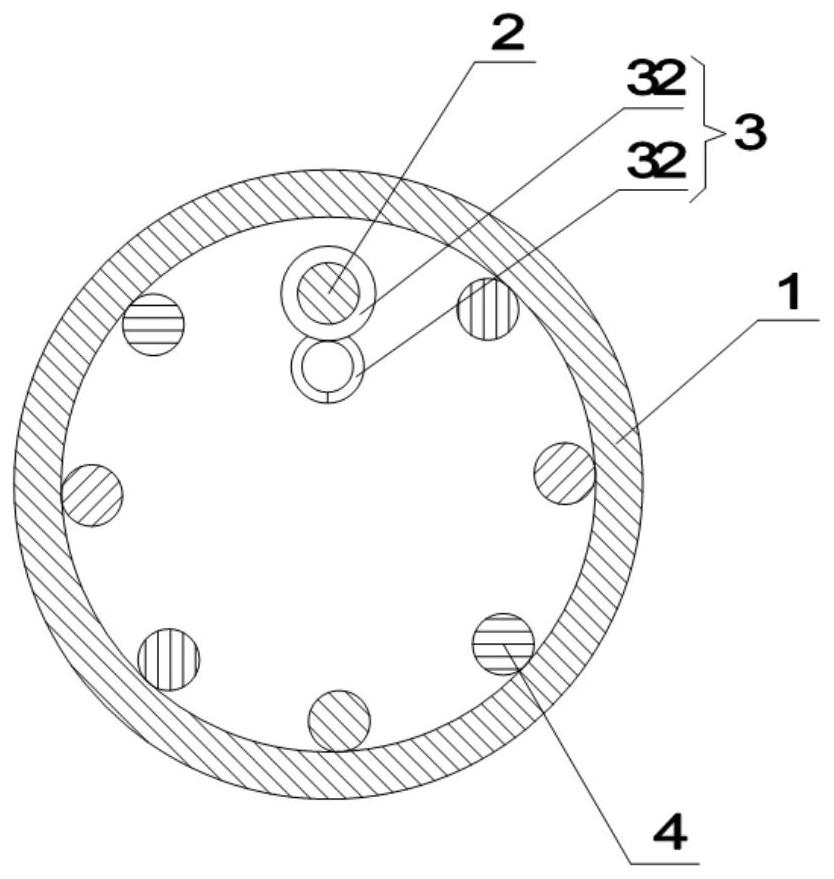

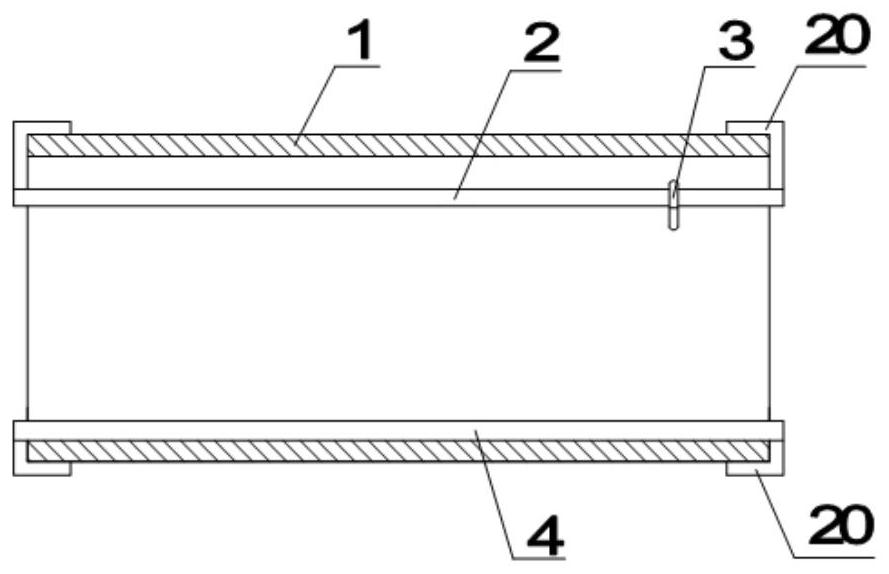

[0039] like figure 1 and figure 2 As shown, first prepare a guide rib 2, a plurality of reinforcing ribs 4 and a buckle 3, and the number of reinforcing ribs 4 in this embodiment is seven. The structure of buckle 3 is as figure 1 As shown, it includes a sliding ring 31 at the top and a guide ring 32 at the bottom. The bottom of the guide ring 32 has an opening that can be closed. An anti-slip layer made of elastic rubber is fixed on the inside.

[0040] Insert the sliding ring 31 of the buckle 3 into the guide rib 2 first, then insert the guide rib 2 and the reinforcing rib 4 into the prestressed bellows 1, and expose the two ends of the guiding rib 2 and the reinforcing rib 4 to the prestressed bellows 1 The par...

Embodiment 2

[0052] The difference between this embodiment and Embodiment 1 is that this embodiment does not use manual beam threading, but uses a 5T winch threading machine. This embodiment is suitable for steel beams with a length of more than 50 m.

Embodiment 3

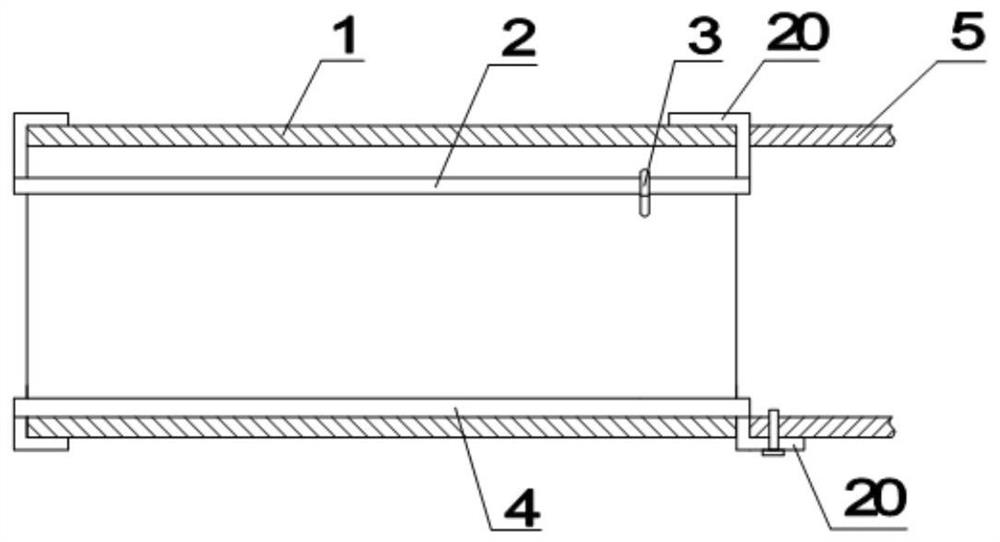

[0054] The difference between this embodiment and embodiment one and embodiment two is: the installation of the anchor end 5 of the steel beam is also included between step B and step C, combined image 3 As shown, when installing, first align the anchor end 5 with the end of the prestressed corrugated pipe 1, and then use a wrench to fasten the fasteners 2 at the ends of each reinforcing rib 4 on the anchor end 5, and then fasten the fasteners 2 with fastening bolts. Being fixed together with the anchor end 5 can strengthen the connection strength between the prestressed bellows 1 and the anchor end 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com