Method to Eliminate Rolling Force Fluctuation After Roll Shifting in Rolling Mill

A technology of rolling force and roll shifting, which is applied in the direction of rolling force/roll gap control, etc. It can solve the problems of rolling force deviation, deviation of scrap steel, poor rolling stability, etc., and achieve the elimination of jumps or fluctuations and small forecast deviation , to ensure a stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

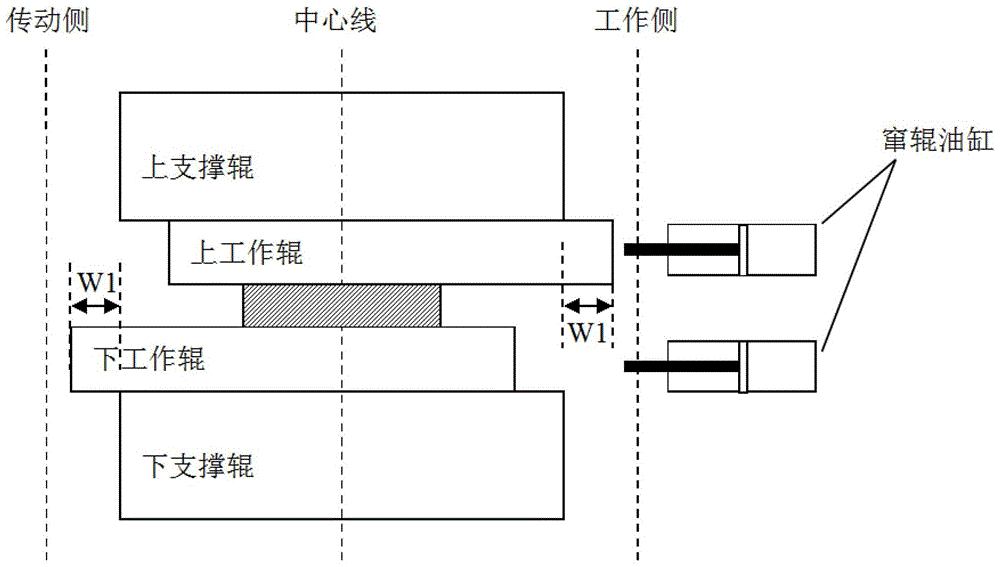

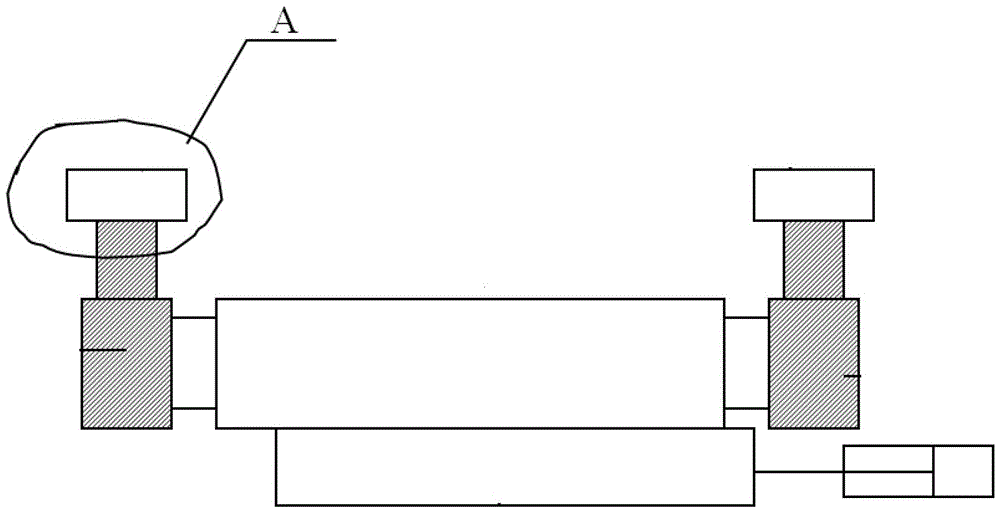

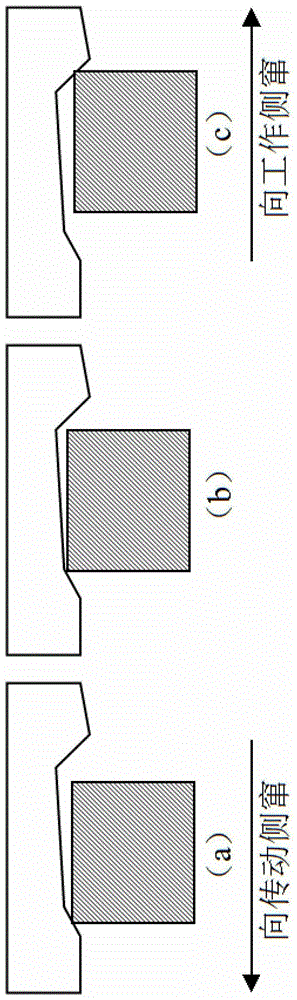

[0034] In order to overcome the influence of the roll shifting direction on the vertical dimension, the Figure 4 The roll shifting positioning method shown, such as Figure 4 As shown, when the roll shifting setting moves to the transmission side (a), the roll shifting L1 directly follows the roll shifting L2 setting to the set position; when the roll shifting setting moves to the working side (b), then Roller shifting L1 first shifts to the working side by Lmm, and then shifts back to the transmission side by Lmm after the positioning is completed, and finally returns to the set roller shifting position. Since the mechanical limit position of roll shifting is ±200mm, if the roll shifting position of roll shifting L2 is set to be ±200mm, the actual roll shifting position of roll shifting L1 will reach (200+L) mm, which may c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com