Anti-cracking flame-retardant cable sheath material and preparation method thereof

A technology for flame-retardant cables and sheathing materials, which is applied to circuits, electrical components, plastic/resin/wax insulators, etc. It can solve the problems of low addition of multifunctional modifiers and poor mechanical properties of cable sheathing materials. Excellent mechanical properties, improved flame retardancy and mechanical properties, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

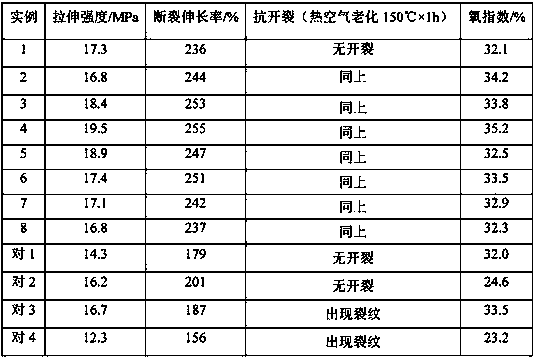

Examples

Embodiment 1

[0026] An anti-cracking flame-retardant cable sheathing material, made of the following parts by weight:

[0027] Linear low-density polyethylene 40 parts, high-density polyethylene 10 parts, methyl vinyl silicone rubber 25 parts, ethylene-octene copolymer 20 parts, hydrogen-containing silicone oil 5 parts, talc 4 parts, aluminum nitride nanoparticles 0.5 Parts, 10 parts of aluminum hydroxide, 6 parts of zinc borate, 1 part of antioxidant, 0.2 part of chloroplatinic acid and 1 part of crosslinking agent.

[0028] The methyl vinyl silicone rubber is vinyl-terminated polydimethylsiloxane, the molecular weight of the vinyl-terminated polydimethylsiloxane is 500,000-700,000, and the vinyl content is 0.05-0.1 mol %.

[0029] The hydrogen-containing silicone oil is polymethylhydrogensiloxane, the molecular weight is 2000-4000, and the hydrogen content is 0.5-2wt%.

[0030] The aluminum nitride nano particles have a particle size of 20-100 nm and a thermal conductivity of 150-320 W / m·K.

[0...

Embodiment 2

[0038] An anti-cracking flame-retardant cable sheathing material, made of the following parts by weight:

[0039] 45 parts of linear low-density polyethylene, 11 parts of high-density polyethylene, 26 parts of methyl vinyl silicone rubber, 22 parts of ethylene-octene copolymer, 5 parts of hydrogen-containing silicone oil, 5 parts of talc powder, 0.8 parts of aluminum nitride nanoparticles Parts, 12 parts of aluminum hydroxide, 7 parts of zinc borate, 1.2 parts of antioxidant, 0.3 parts of chloroplatinic acid and 1.5 parts of crosslinking agent.

[0040] The methyl vinyl silicone rubber is vinyl-terminated polydimethylsiloxane, the molecular weight of the vinyl-terminated polydimethylsiloxane is 500,000-700,000, and the vinyl content is 0.05-0.1 mol %.

[0041] The hydrogen-containing silicone oil is polymethylhydrogensiloxane, the molecular weight is 2000-4000, and the hydrogen content is 0.5-2wt%.

[0042] The aluminum nitride nano particles have a particle size of 20-100 nm and a t...

Embodiment 3

[0050] An anti-cracking flame-retardant cable sheathing material, made of the following parts by weight:

[0051] 48 parts of linear low-density polyethylene, 12 parts of high-density polyethylene, 28 parts of methyl vinyl silicone rubber, 24 parts of ethylene-octene copolymer, 6 parts of hydrogen-containing silicone oil, 5 parts of talc powder, 1 part of aluminum nitride nanoparticles Parts, 14 parts of aluminum hydroxide, 7 parts of zinc borate, 7 parts of antioxidant, 0.1 part of chloroplatinic acid and 2 parts of crosslinking agent.

[0052] The methyl vinyl silicone rubber is vinyl-terminated polydimethylsiloxane, the molecular weight of the vinyl-terminated polydimethylsiloxane is 500,000-700,000, and the vinyl content is 0.05-0.1 mol %.

[0053] The hydrogen-containing silicone oil is polymethylhydrogensiloxane, the molecular weight is 2000-4000, and the hydrogen content is 0.5-2wt%.

[0054] The aluminum nitride nano particles have a particle size of 20-100 nm and a thermal c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com