Glass fiber reinforced plastic pipeline production method

A production method and glass fiber reinforced plastic technology, which can be applied to tubular articles, other household appliances, household appliances, etc., can solve the problems of uneven glass fiber filaments, rough surface of glass fiber reinforced plastic pipes, affecting the quality of glass fiber reinforced plastic pipes, etc., so as to reduce the winding layer. Different thickness, uniform gluing amount and small gluing amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

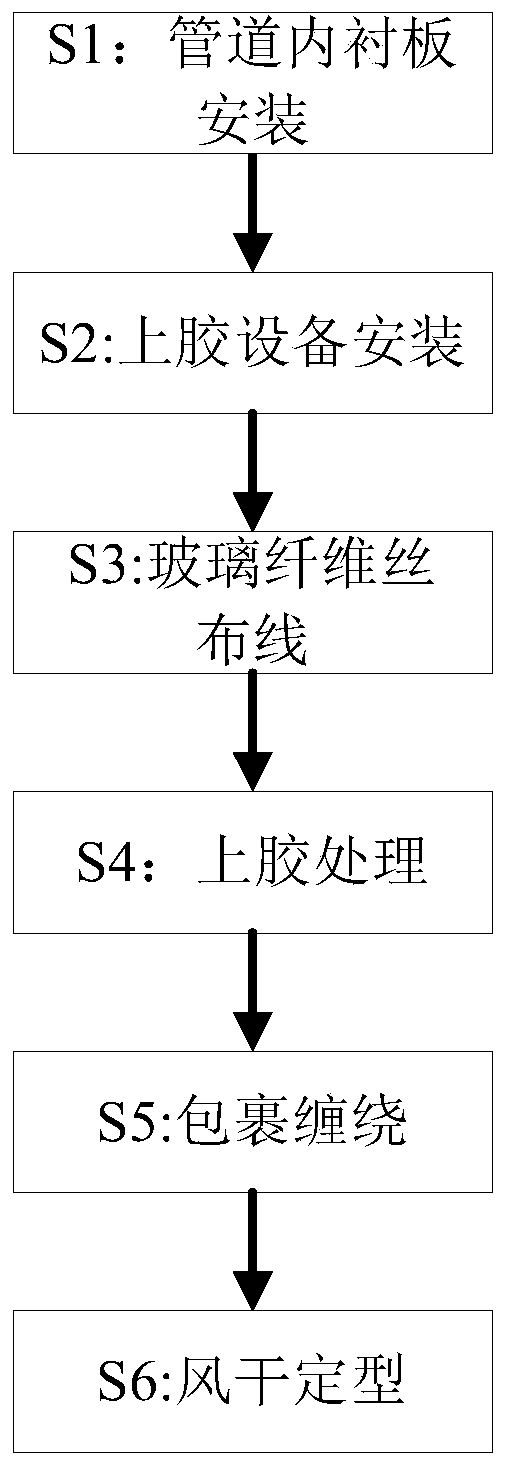

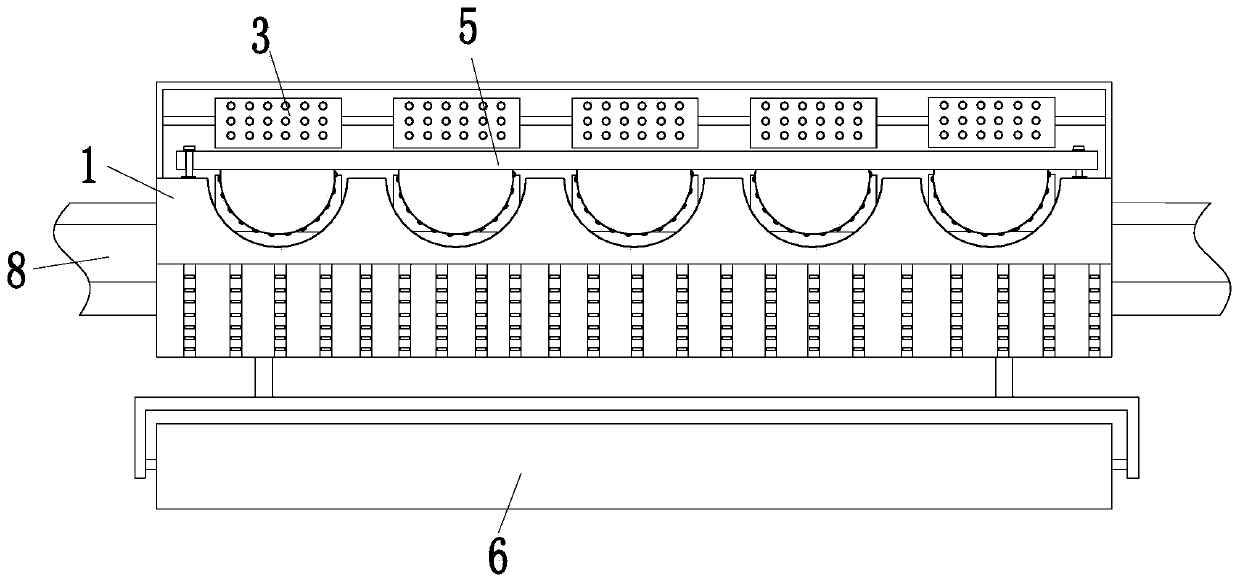

[0038] Such as Figure 1 to Figure 7 Shown, a kind of FRP pipe production method is characterized in that: the specific production method is as follows:

[0039] S1. Pipeline lining installation: install the two ends of the pipeline lining, and control the low-speed rotation of the pipeline lining through an external drive;

[0040] S2. Installation of gluing equipment: install the gluing equipment directly above the inner lining of the pipeline, and arrange the gluing equipment parallel to the inner lining of the pipeline;

[0041] S3. Wiring of glass fiber wires: set the reel-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com