Constant-temperature mineral casting device sleeving machine tool mold and manufacturing method thereof

A technology of mineral castings and production methods, applied in metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problems of poor constant temperature effect of machine tools, achieve good cooling effect, increase cooling area, and provide cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

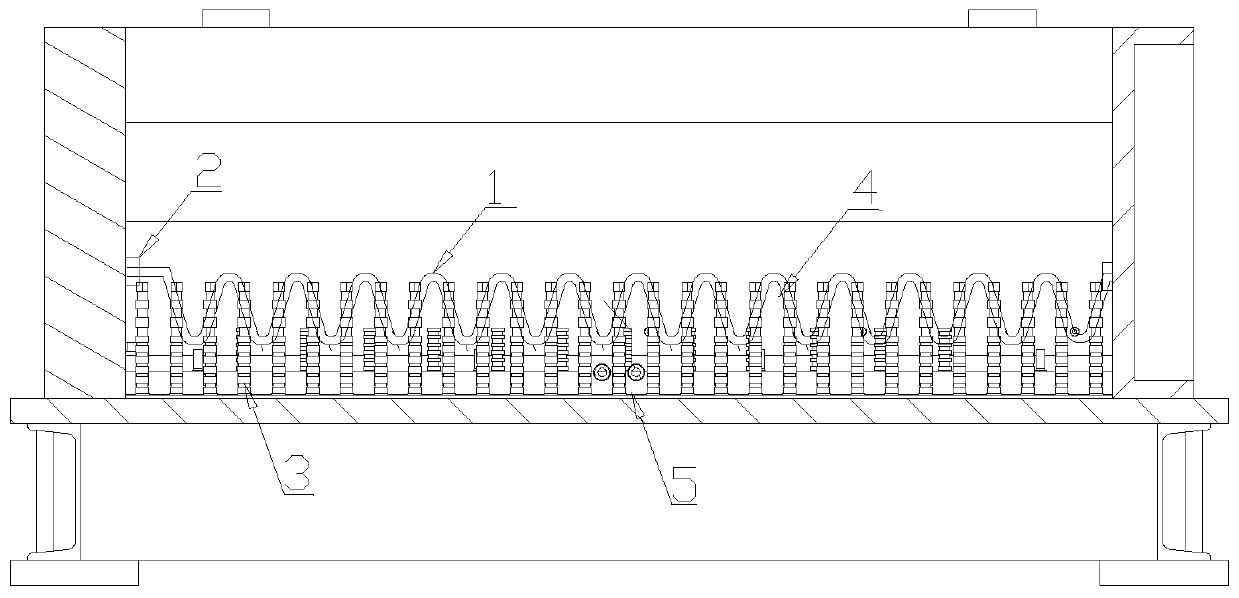

[0022] A constant temperature mineral casting device set on the mold of the machine tool, such as figure 1 As shown, it includes a cooling copper pipe 1, a pipe joint 2, a brace 3 and an iron wire 4, and both ends of the cooling copper pipe 1 are equipped with a pipe joint 2, and the pipe joint 2 and the brace 3 are bound together by the iron wire 4; the brace 3 Fixedly locked on the machine tool mold 5. The diameter of the cooling copper tube 1 is 8 mm. The diameter of iron wire 4 is 0.8 millimeter. The cooling copper pipe 1 is corrugated.

[0023] A method for manufacturing a constant temperature mineral casting device set on a machine tool mold, comprising the following steps:

[0024] 1. Bending the cooling copper tube 1 with a diameter of 8 mm in a wave shape with a tube bender;

[0025] 2. Cut out the length of the corresponding cooling copper pipe 1 according to the length requirement of the line rail of the machine bed;

[0026] 3. Install the pipe joint 2 on both...

Embodiment 2

[0031] A constant temperature mineral casting device set on the mold of the machine tool, such as figure 1 As shown, it includes a cooling copper pipe 1, a pipe joint 2, a brace 3 and an iron wire 4, and both ends of the cooling copper pipe 1 are equipped with a pipe joint 2, and the pipe joint 2 and the brace 3 are bound together by the iron wire 4; the brace 3 Fixedly locked on the machine tool mold 5. The diameter of the cooling copper tube 1 is 12 mm. The diameter of iron wire 4 is 1.5 millimeters. The cooling copper pipe 1 is corrugated.

[0032] A method for manufacturing a constant temperature mineral casting device set on a machine tool mold, comprising the following steps:

[0033] 1. Bending the cooling copper tube 1 with a diameter of 12 mm in a wave shape with a tube bender;

[0034] 2. Cut out the length of the corresponding cooling copper pipe 1 according to the length requirement of the line rail of the machine bed;

[0035] 3. Install the pipe joint 2 on b...

Embodiment 3

[0040] A constant temperature mineral casting device set on the mold of the machine tool, such as figure 1 As shown, it includes a cooling copper pipe 1, a pipe joint 2, a brace 3 and an iron wire 4, and both ends of the cooling copper pipe 1 are equipped with a pipe joint 2, and the pipe joint 2 and the brace 3 are bound together by the iron wire 4; the brace 3 Fixedly locked on the machine tool mold 5. The diameter of the cooling copper pipe 1 is 10 mm. The diameter of iron wire 4 is 1 millimeter. The cooling copper pipe 1 is corrugated.

[0041] A method for manufacturing a constant temperature mineral casting device set on a machine tool mold, comprising the following steps:

[0042] 1. Bending the cooling copper tube 1 with a diameter of 10 mm in a wave shape with a tube bender;

[0043] 2. Cut out the length of the corresponding cooling copper pipe 1 according to the length requirement of the line rail of the machine bed;

[0044] 3. Install the two ends 1 of the cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com