Improved structure of lead melting furnace of cast-welding machine

A technology of lead melting furnace and casting welding machine, which is applied in the field of lead melting furnace, can solve the problems of reducing the service life of other parts, changing the accuracy of the overall frame, and harming the health of personnel, so as to prolong the service life, reduce heat radiation, improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

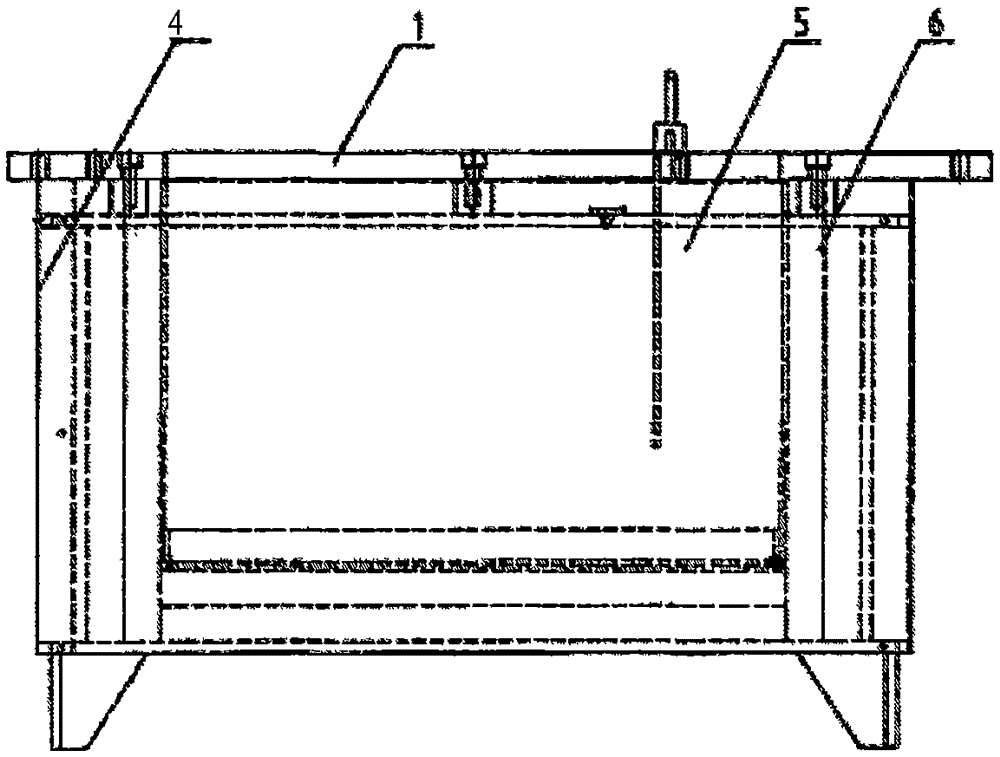

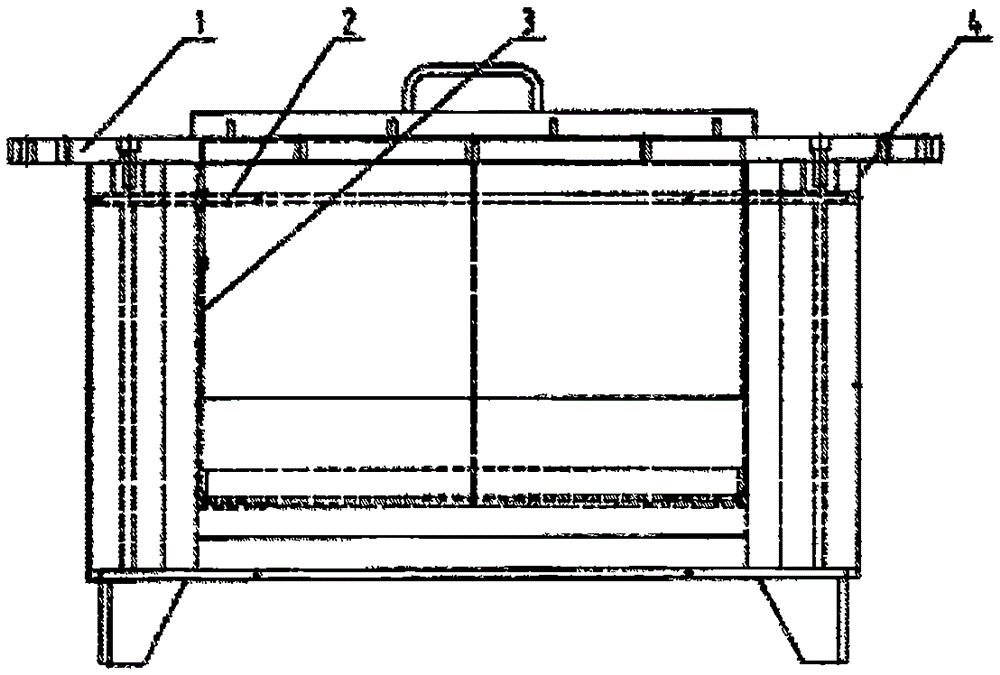

[0018] Such as figure 1 with figure 2 As shown, in one embodiment, the lead-melting furnace used in the casting welding machine provided by the present invention includes a furnace body 2, a furnace furnace 3 and a platen 1, wherein the furnace body is a five-sided closed frame body, and the furnace body The liner 3 is arranged in the furnace body 2, and 2 layers of asbestos insulation boards 6 are also arranged on the inner wall of the furnace body 2, which can reduce heat transfer to the outside, and also reduce the temperature rise of the overall frame while saving electricity. 2 Baffles are also arranged around the outer wall, which can prevent heat from being transmitted outside again like this, and can also reduce the temperature around the equipment at the same time. The lead-melting furnace with the structure of the present invention can reduce the accuracy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com