A traction system for clamping glass by short rollers and its application method

A traction system and short roller technology, which is applied to the traction system field of short rollers clamping glass, can solve the problems of glass cracking, insufficient clamping force, large limitations, etc., and achieve the effect of saving cost and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

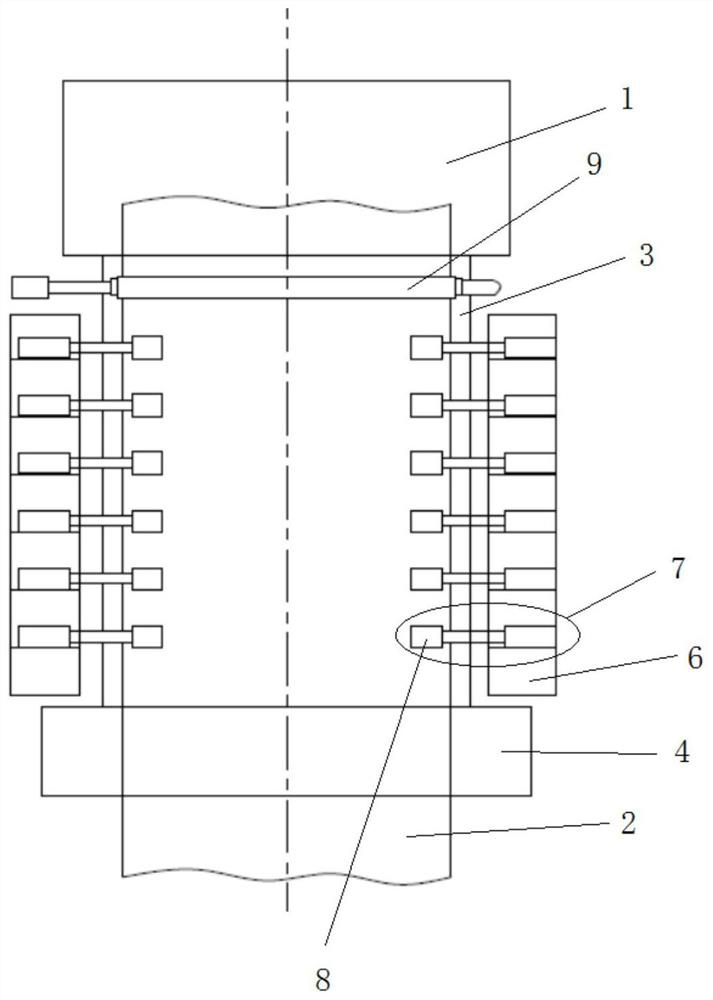

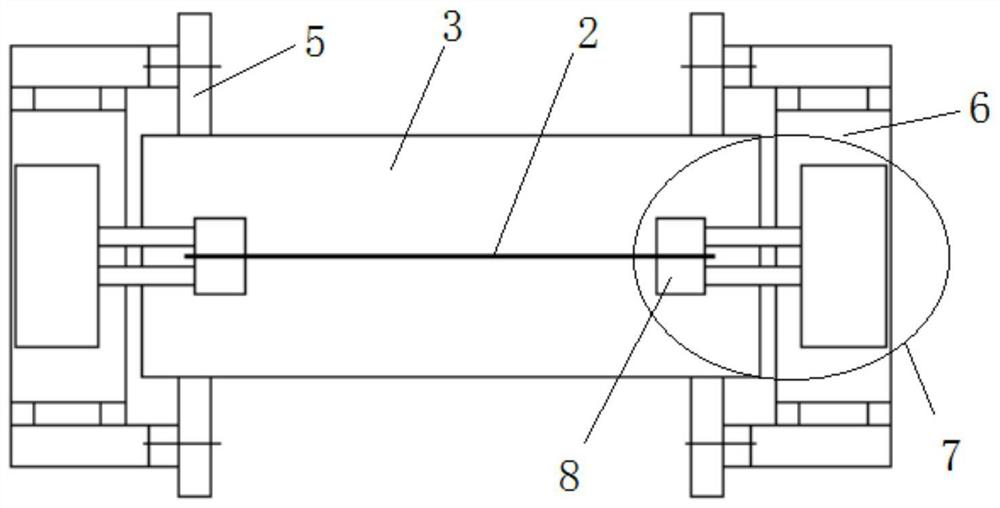

[0036] see figure 1 and figure 2 , the traction system of the present invention for clamping glass by short rollers is located between the overflow device 1 and the cutting device 4, and includes a support arm 5, a bracket 6 and a short roller mechanism 7;

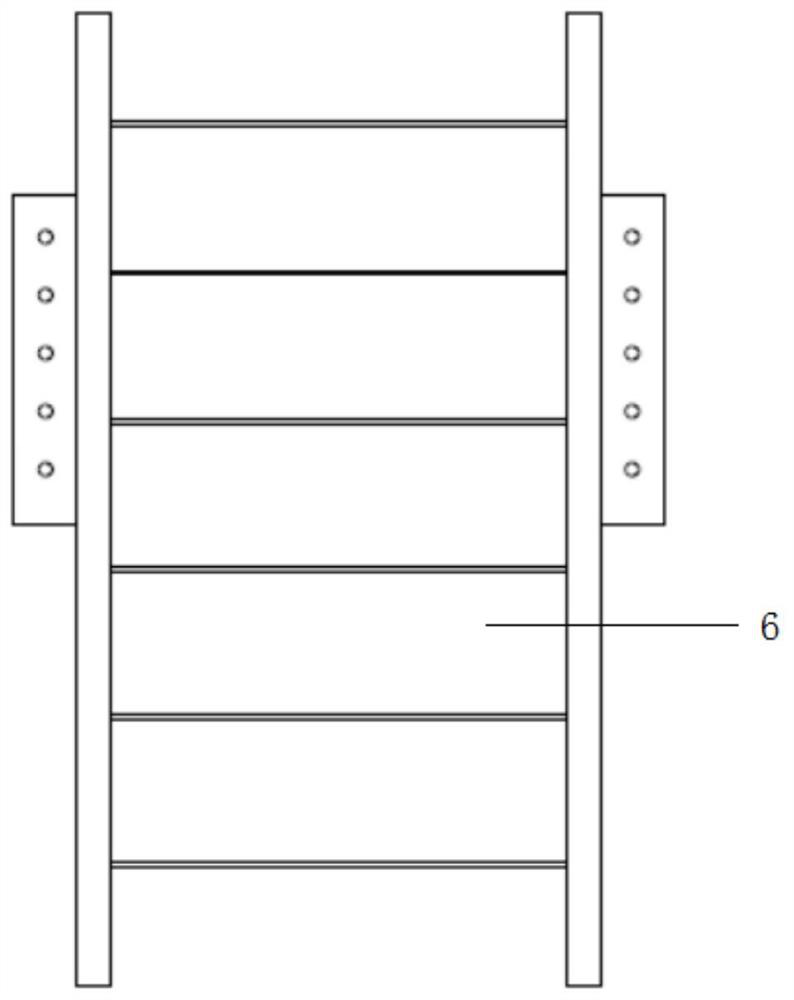

[0037] Two support arms 5 are respectively arranged at the middle height of both sides of the annealing furnace 3. The support arms 5 are used to support the annealing furnace 3 and are distributed at the four corners of the annealing furnace 3. There are two supports 6, which are symmetrically fixed on both sides of the annealing furnace 3 respectively. On the support arm 5, the structure of the bracket 6 is as follows image 3 and Figure 4 As shown, no less than three platforms are fixedly arranged on the support 6, and the platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com