Aminated graphene oxide and graphite phase carbon nitride composite modified film material and preparation method and application thereof

A graphite phase carbon nitride and composite modification technology, applied in the field of environment and water treatment, can solve the problems of narrow spectral response range, weak anti-pollution performance, low photocatalytic efficiency, etc., and achieve improved anti-pollution performance and anti-pollution performance. Improved, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

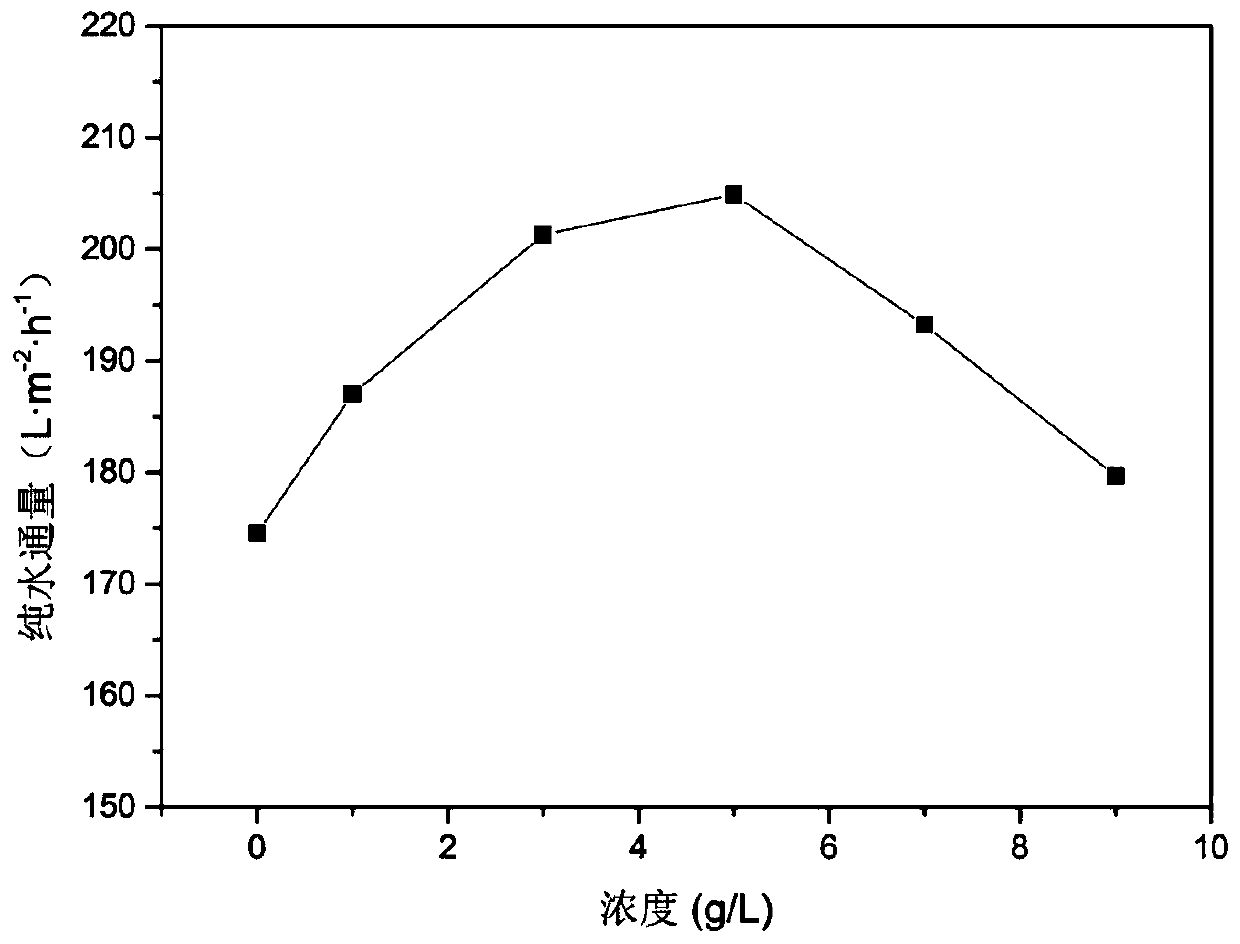

[0088] The influence of embodiment 1 SDBS concentration

[0089] Use anionic surfactant sodium dodecylbenzene sulfonate (SDBS) to carry out pretreatment to polysulfone original membrane original membrane (polysulfone original membrane is also called original membrane, polysulfone hollow fiber organic ultrafiltration membrane, the same below), so that Activated polysulfone original membrane and hydrophilic material SLg-C 3 N 4 / NGO heterojunction is firmly combined to improve membrane flux.

[0090] Prepare SDBS solutions of 1g / L, 3g / L, 5g / L, 7g / L, and 9g / L respectively, and place the original polysulfone membranes in different concentrations of SDBS solutions for 10 minutes, then take them out, and measure their pressure at 0.20MPa. The initial pure water flux under conditions.

[0091] Such as figure 1 As shown, with the increase of SDBS concentration, the pure water flux of the membrane also increased continuously. When the SDBS concentration is 5g / L, the pure water flu...

Embodiment 2

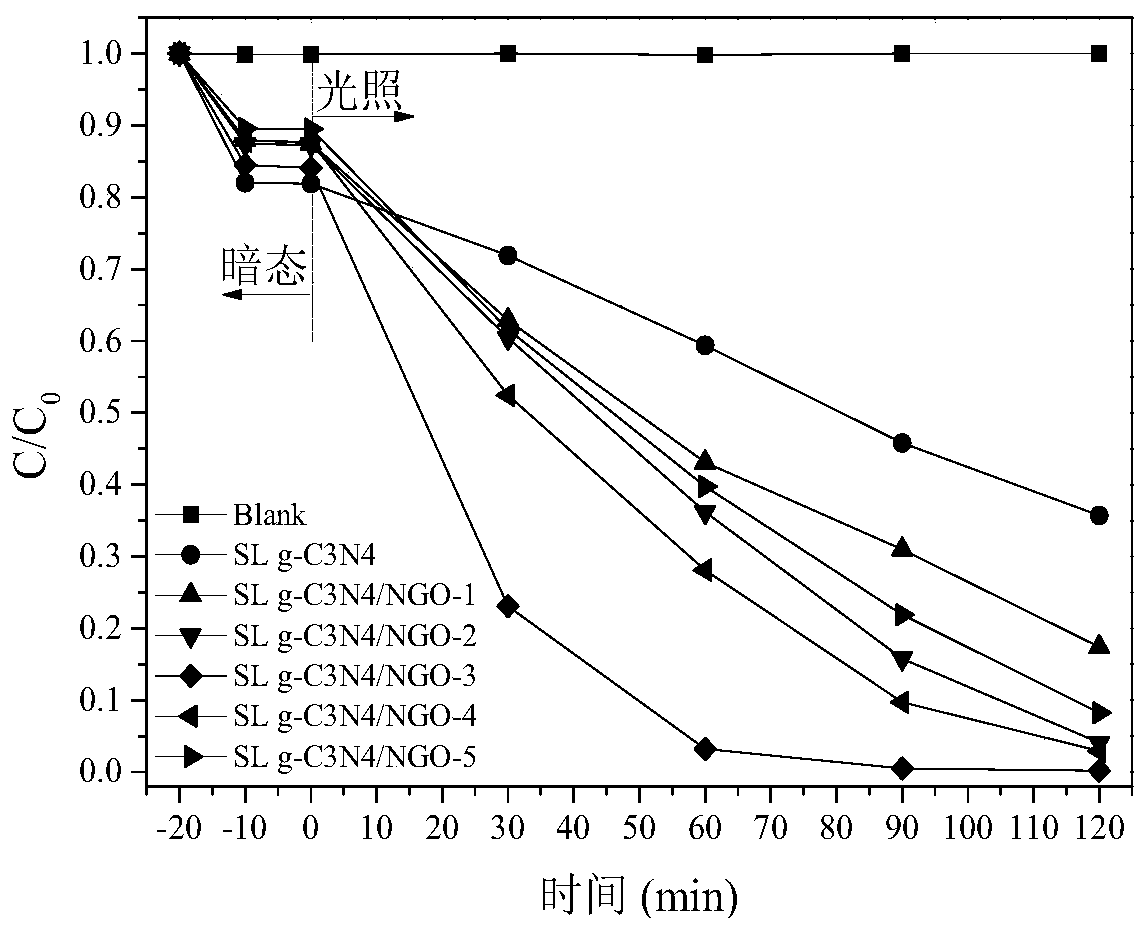

[0092] Example 2 SL g-C 3 N 4 Influence of mass fraction of NGO in NGO heterojunction

[0093] Take 100mg SL g-C 3 N 4 Add a certain amount of NGO to the ratio solution of water and ethanol (water:ethanol ratio is 1:1), sonicate for 4 hours, and finally centrifuge the solid product, wash it repeatedly with water and ethanol respectively, and dry the product at 80°C to obtain SL g-C 3 N 4 / NGO heterojunction. By controlling the amount of NGO added (1wt%, 2wt%, 3wt%, 4wt%, 5wt%), SL g-C with different NGO loadings were prepared respectively 3 N 4 / NGO heterojunction, denoted as SL g-C 3 N 4 / NGO-1, SL g-C 3 N 4 / NGO-2, SL g-C 3 N 4 / NGO-3, SL g-C 3 N 4 / NGO-4, SL g-C 3 N 4 / NGO-5.

[0094] The effect of the mass fraction of NGO in the heterojunction on the visible light degradation of RhB is as follows: figure 2 shown. Under blank conditions, stirring for 20min under dark conditions and 120min of visible light irradiation, RhB did not degrade (see figure 2...

Embodiment 3

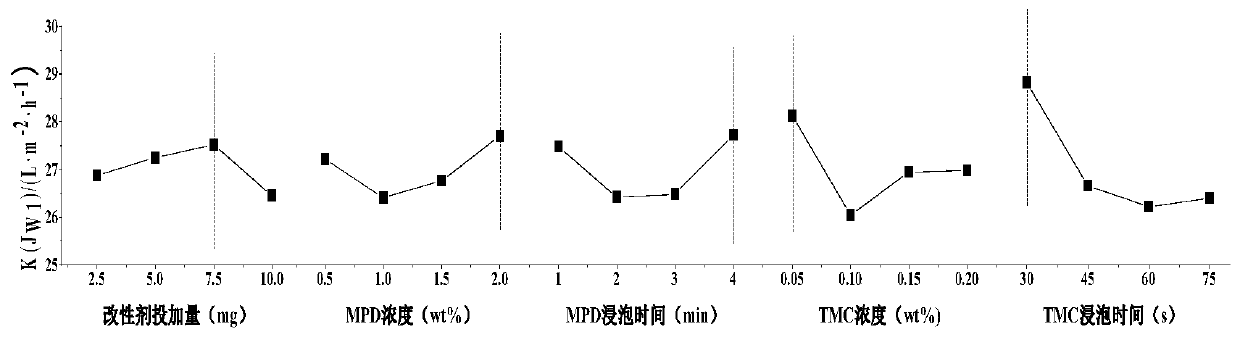

[0095] Embodiment 3 Orthogonal Test

[0096] In this example, the SL g-C is preliminarily determined through a multi-index orthogonal test 3 N 4 / NGO composite modified membrane (also known as SL g-C 3 N 4 / NGO composite modified polyamide membrane, composite modified membrane, composite membrane, modified membrane, the same below). SL g-C obtained from orthogonal experiments 3 N 4 The optimal preparation conditions of the / NGO composite modified polyamide membrane are shown in Table 1. This embodiment selects 5 influencing factors: SL g-C 3 N 4 Dosing amount, MPD concentration, MPD immersion time, TMC concentration, TMC immersion time (abbreviated as D 改性剂 、C MPD , t MPD 、C TMC , t TMC ), set 4 levels for each factor, and use the performance parameter index of the composite modified polyamide membrane to determine the primary and secondary order of each influencing factor in the modified membrane through the R value of the range, and determine the SL g-C 3 N 4 O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com