Shear wall composed of corrugated steel sheets and concrete-filled steel tubular members

A technology of concrete filled steel tubes and corrugated steel plates, which is applied to building components, walls, building structures, etc., can solve the problems of difficult welding of vertical plates, low factory efficiency, affecting internal concrete filling, etc., and achieves high flexural rigidity. Good mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

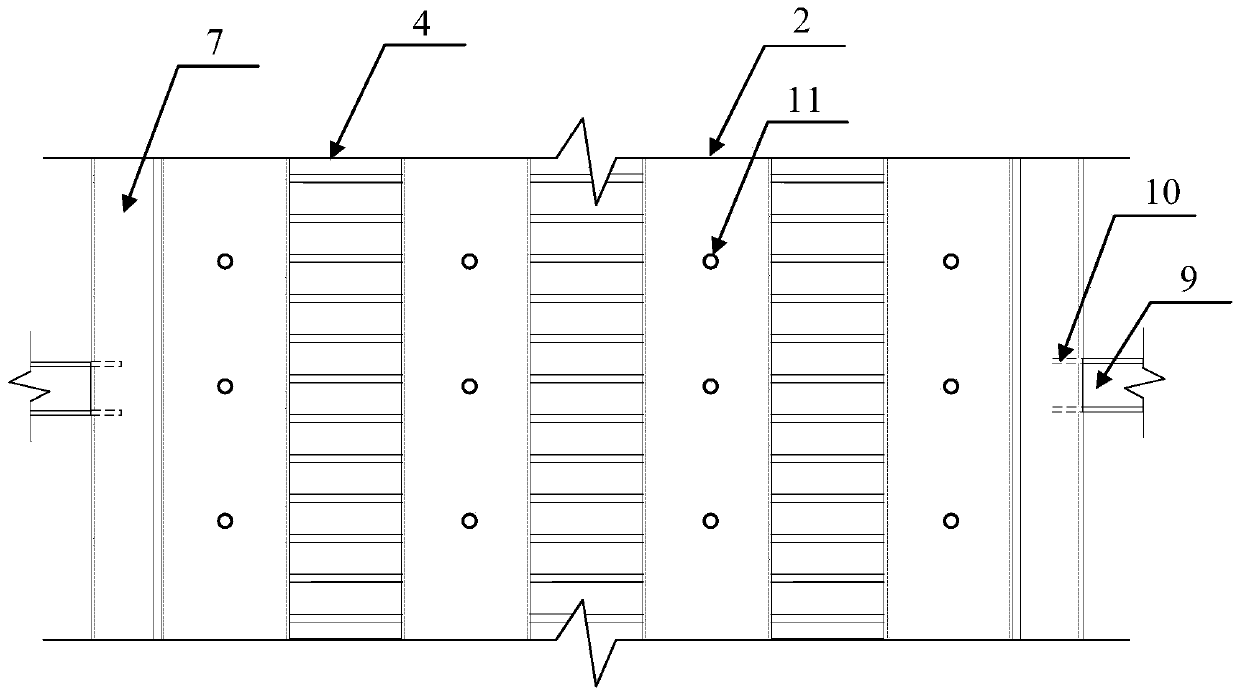

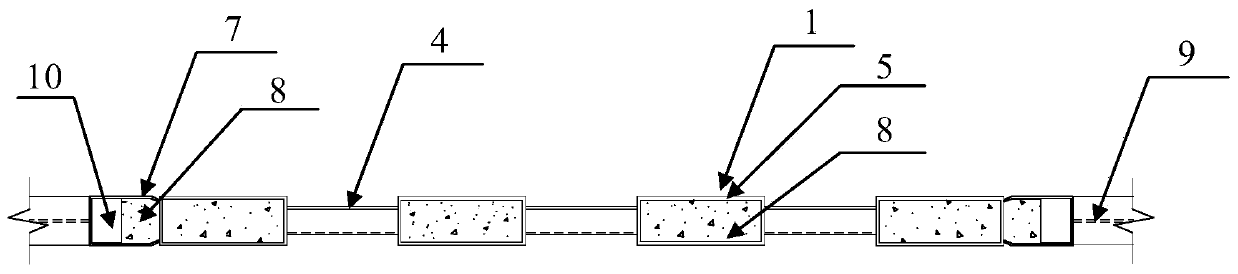

[0029] The implementation of the present invention will be described in detail below in conjunction with accompanying drawings 1 to 3, and the content is an explanation of the present invention rather than a limitation. In the picture:

[0030] 1——rectangular steel tube concrete member;

[0031] 2——Concrete steel tube members with tension bolts;

[0032] 3—Square steel pipe concrete member;

[0033] 4—corrugated steel plate;

[0034] 4-1——corrugated steel plate;

[0035] 4-2——Trapezoidal corrugated steel plate;

[0036] 4-3——rectangular corrugated steel plate;

[0037] 5 - rectangular steel pipe;

[0038] 6 - square steel pipe;

[0039] 7—C-shaped section cold-formed steel vertical edge member;

[0040] 8 - concrete;

[0041] 9——steel beam;

[0042] 10——horizontal horizontal partition;

[0043] 11——High-strength bolts.

[0044] As shown in Figures 1-2, the shear wall composed of corrugated steel plates and steel tube concrete members includes a rectangular steel tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com