Steam device for fiber throwing centrifuge, ceramic fiber steam fiber throwing centrifuge and fiber making system

A ceramic fiber, spinning machine technology, applied in fiber processing, textile and papermaking, filament/thread forming, etc., can solve problems such as steam, and achieve the effect of separation and avoidance of drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

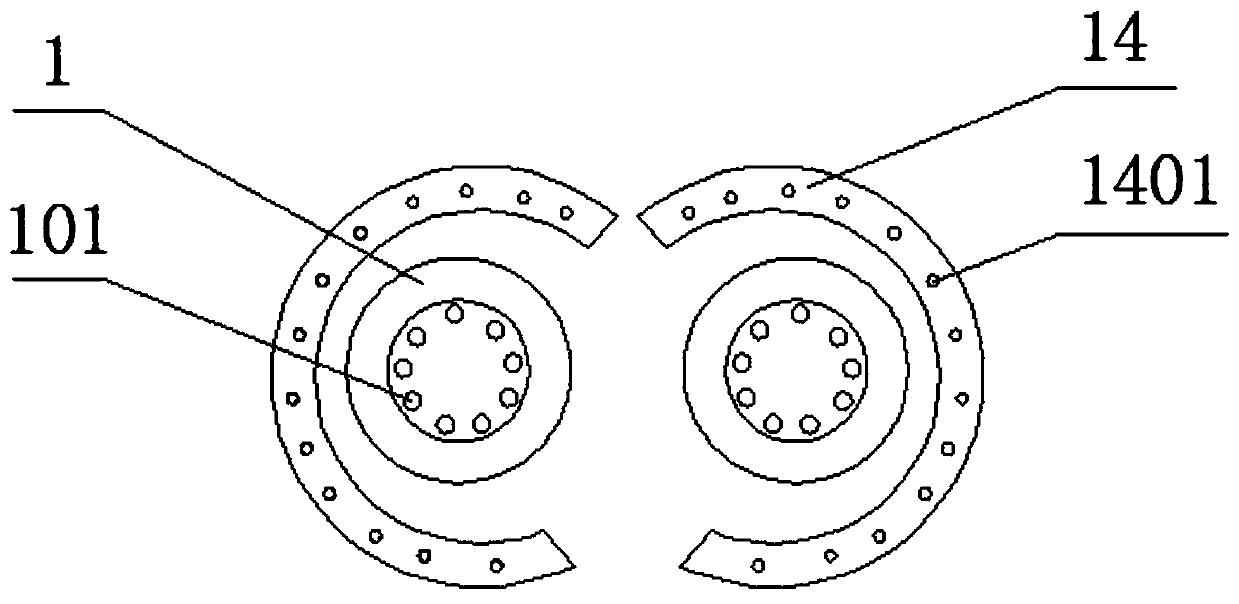

[0072] as attached figure 1 As shown, a steam device of the present invention for a spinning machine, the steam device includes a spinning head 1, a nozzle 2 and a water supply device, and is applied to a ceramic fiber spinning machine in which the spinning roller shaft 8 is a hollow shaft .

[0073] The roller head 1 is a hollow tubular structure. One of the two ends of the roller head 1 is the outlet end, and the other end is the inlet end. The outlet end of the roller head 1 is a blind end with multiple exhaust ports. The hole 101, the inlet end of the roller head 1 is an open end.

[0074] The nozzle 2 is a soft water pipe, one of the two ends of the nozzle 2 is the outlet end, and the other end is the inlet end, the outlet end of the nozzle 2 is a blind end and is built in the roller head 1, and the nozzle 2 is A plurality of drainage holes 201 are provided on the pipe wall located in the roller head 1; the inlet end of the nozzle 2 is an open end, and the inlet end of ...

Embodiment 2

[0084] as attached figure 2 - attached Figure 5 As shown, the ceramic fiber steam spinning machine of the present invention includes a frame 23, a pair of spinning rollers, a steam device, and a spinning drive device. The steam device is the steam device disclosed in Embodiment 1 for the spinning machine.

[0085] Wherein, this pair of spinning rollers is rotatably connected on the frame 23 by the roller shaft pillow 9, and the spinning roller roller shaft 8 is a hollow shaft.

[0086] In the steam device, there are two roller heads 1, nozzle pipes 2 and water supply pipes 3 corresponding to the silk rollers one by one, and the roller head 1 is connected to the output end of the roller shaft 8 of the silk roller and communicated with the roller shaft 8 of the silk roller , the inlet end of spray pipe 2 is fixedly connected on the inner wall of the output end of spinning roller shaft 8, and nozzle pipe 2 is used as the only communication channel between spinning roller head ...

Embodiment 3

[0099] The present invention provides a ceramic fiber spinning system, comprising a melting furnace 21, a spinning machine, a cotton collector 17 and an induced draft fan. The melting furnace 21 includes a furnace body. It is used for the high-temperature ceramic fiber molten juice to flow out; the spinning machine is the spinning machine disclosed in Embodiment 2, and the spinning machine is arranged under the melting furnace 21, and two spinning rollers are arranged in parallel at the spout 22 along the horizontal direction The bottom of the ceramic fiber melt juice is used to make ceramic fibers; the cotton collector 17 includes a housing, and a cotton inlet 1701 is formed on the housing, and the cotton inlet 1701 is located at the output side of the two rejection roller heads 1, for Collect ceramic fiber; induced draft fan is used for ceramic fiber suction cotton collector 17.

[0100] In this embodiment, the cotton collector 17 housing is provided with a conveying mesh be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com