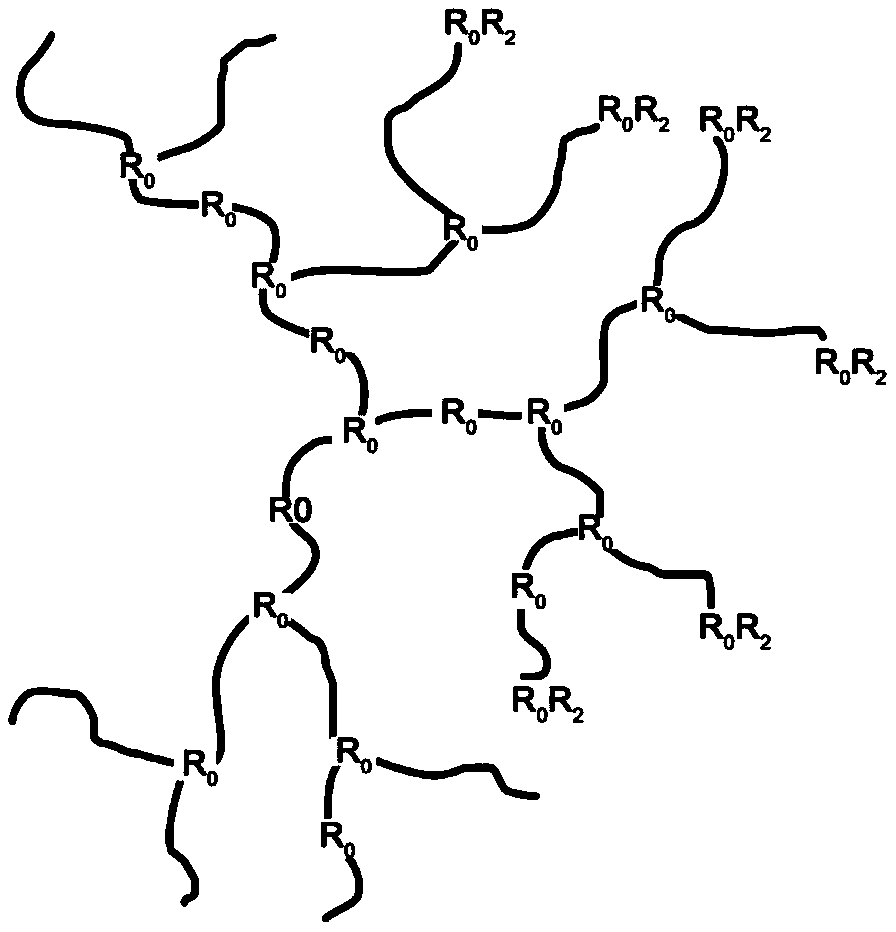

Special super-plasticizer for manufactured sand concrete and preparation method thereof

A superplasticizer and concrete technology, applied in the field of concrete superplasticizer, can solve the problems of high viscosity of machine-made sand concrete, insufficient initial workability, rapid loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] (1) Add 4.43 parts of dioxane to the reactor under anhydrous conditions, add 3.658 parts of B1 to it, stir and dissolve, adjust the reactor to 80°C, and at the same time add 0.942 parts of C1 continuously and uniformly within 6 hours, After adding, continue to stir and react for 6h to obtain the intermediate solution;

[0087] (2) Add 1.884 parts of dioxane and 1.884 parts of E1 to another anhydrous reactor, stir to dissolve, adjust the reactor to 80°C, add 0.00540 parts of sodium methoxide, and continuously and uniformly add step (1) The intermediate solution prepared, after adding and continuing to stir and react for 6 hours, a new intermediate solution is obtained;

[0088] (3) Add 3.484 parts of dioxane and 3.484 parts of B1 to the third anhydrous reactor, stir to dissolve, adjust the reactor to 80°C, add 0.00540 parts of sodium methoxide, and continuously and uniformly add it within 6 hours The intermediate solution prepared in step (2), after the addition is comp...

Embodiment 2

[0094] (1) Add 19.88 parts of dimethyl sulfoxide to the reactor under anhydrous conditions, add 5.206 parts of B2 to it, stir and dissolve, adjust the reactor to 150°C, add 0.144 parts of sodium tert-butoxide to it, and within 1h A solution of 1.422 parts of C2 dissolved in 1.422 parts of dimethyl sulfoxide is continuously and uniformly added, and the stirring reaction is continued for 1 hour after adding to obtain an intermediate solution;

[0095] (2) Add 15.024 parts of dimethyl sulfoxide and 5.258 parts of E2 to another anhydrous reactor, stir to dissolve, adjust the reactor to 150°C, add 0.1922 parts of sodium tert-butoxide, and continuously and uniformly Add the intermediate solution prepared in step (1), and after adding, continue to stir and react for 3 hours to obtain a new intermediate solution;

[0096] (3) Add 120 parts of dimethyl sulfoxide and 40 parts of B5 to the third anhydrous reactor, stir to dissolve, adjust the reactor to 150°C, add 0.3844 parts of sodium ...

Embodiment 3

[0102] (1) Add 13.68 parts of N,N-dimethylformamide to the reactor under anhydrous conditions, add 6.068 parts of B3 to it, stir to dissolve, adjust the reactor to 100°C, and add 0.0449 parts of tert-butyl to it Potassium alkoxide, while continuously and uniformly adding 0.772 parts of C3 to it within 2 hours, after adding, continue to react for 4 hours to obtain an intermediate solution;

[0103] (2) Add 4.628 parts of N,N-dimethylformamide and 2.314 parts of E3 to another anhydrous reactor, stir to dissolve, adjust the reactor to 120°C, add 0.0337 parts of potassium tert-butoxide, and Continuously and uniformly add the intermediate solution prepared in step (1) to it, and obtain a new intermediate solution after adding and continuing to react for 6 hours;

[0104] (3) Add 31.24 parts of N,N-dimethylformamide and 15.62 parts of B2 to the third anhydrous reactor, stir to dissolve, adjust the reactor to 120°C, add 0.0674 parts of potassium tert-butoxide, and at the same time A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com