A method for preparing nanomaterials with different dimensions based on the same metal iron ion

A technology of nanomaterials and the same metal, applied in the field of electrochemical materials, can solve the problems of low energy density of low-dimensional material electrodes, achieve excellent electrical properties, improve performance, reduce internal resistance and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

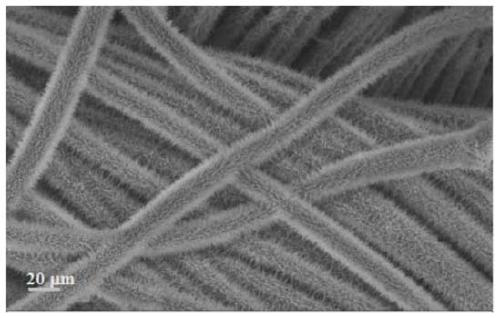

[0041] 1) Preparation of FeCo 2 S 4 nanowire array

[0042] Using deionized water as solvent, prepare 60mL reaction aqueous solution containing 0.6M Urea, 0.6MNH 4 F, 0.2M Co(Cl) 2 ·6H 2 O, 0.1M Fe(Cl) 2 ·6H 2 O. Ultrasonic the cleaned carbon cloth for 30 minutes in the above reaction aqueous solution to make its surface fully contact with the solution, then place it in a 100mL reaction kettle containing the above reaction solution, react at 120°C for 12h, and cool to room temperature. A light pink film was obtained on the surface of the carbon cloth, the sample was rinsed with deionized water, and iron-cobalt hydrate in the shape of nanowires was obtained after drying.

[0043] Prepare 60mL of 0.01M sodium sulfide nonahydrate aqueous solution, put the carbon cloth with iron cobalt hydrate obtained above into a 100mL reaction kettle containing sodium sulfide nonahydrate aqueous solution, react at 90°C for 10h, cool to room temperature, and A layer of black film was obta...

Embodiment 2

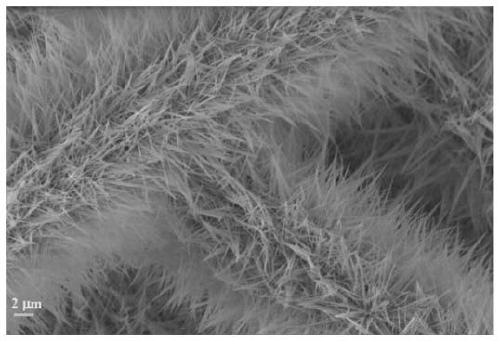

[0048] Prepare 60mL reaction solution containing 0.6M Urea, 0.6M NH 4 F, 0.2MCo(Cl) 2 ·6H 2 O, 0.2MFe(Cl) 2 ·6H 2 O, the solvent is 20ml of deionized water and 40ml of ethanol, put the cleaned carbon cloth into a 100mL reaction kettle containing the above reaction solution, and react at 200°C for 12h. After the reaction, cool to room temperature to obtain a light yellow film , rinse the sample with deionized water, and dry the iron-cobalt hydrate with nanosheet morphology.

[0049] Prepare 60mL of 0.01M sodium sulfide nonahydrate aqueous solution, put the carbon cloth with iron cobalt hydrate obtained above into a 100mL reaction kettle containing sodium sulfide nonahydrate aqueous solution, react at 90°C for 10h, cool to room temperature, and A layer of black film is obtained on the surface of carbon cloth, rinsed with deionized water, and dried to obtain FeCo 2 S 4 nanosheet structure. Such as Figure 5-6 As shown, it can be seen that FeCo 2 S 4 The nanosheets are e...

Embodiment 3

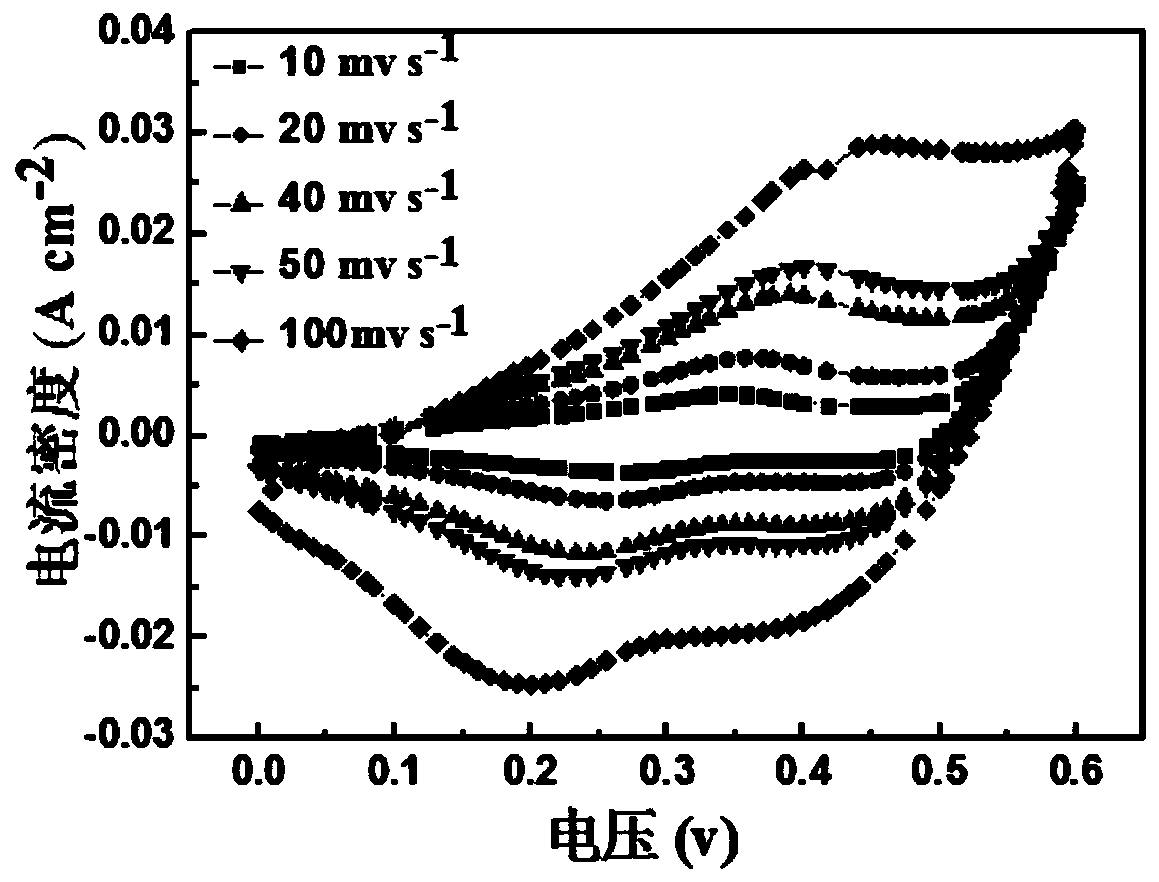

[0052] Using deionized water as solvent, prepare 60mL reaction aqueous solution containing 0.6M Urea, 0.6MNH 4 F, 0.2M Co(Cl) 2 ·6H 2 O, 0.1M Fe(Cl) 2 ·6H 2 O. Ultrasonic the cleaned carbon cloth for 30 min in the above reaction aqueous solution to make its surface fully contact with the solution, then place it in a 100mL reaction kettle containing the above reaction aqueous solution, react at 120°C for 12h, cool to room temperature, and place on carbon A layer of pale pink film was obtained on the surface of the cloth, and the sample was rinsed with deionized water. After drying, the above sample was put into 60mL reaction solution containing 0.6M Urea, 0.6M NH 4 F, 0.2MCo(Cl) 2 ·6H 2 O, 0.2M Fe(Cl) 2 ·6H 2 O, the solvent is 20ml of deionized water and 40ml of ethanol, and then placed in a 100mL reactor, reacted for 12h at 200°C, after the reaction, cooled to room temperature to obtain a darker black film than the sample in Example 1, deionized Rinse the sample with w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com