Automobile planetary gear transmission

A technology of speed change device and planetary gear, applied in the field of automobile transmission system, can solve the problems of complex structure of planetary gear mechanism, large shifting impact, complicated power transmission, etc., to solve different driving requirements, good power transmission and speed change, investment low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

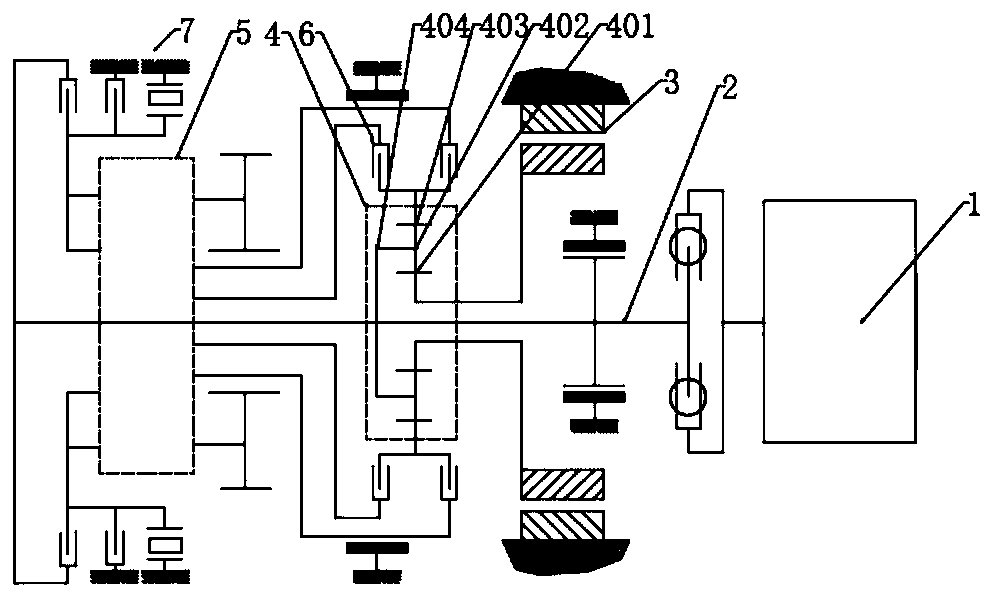

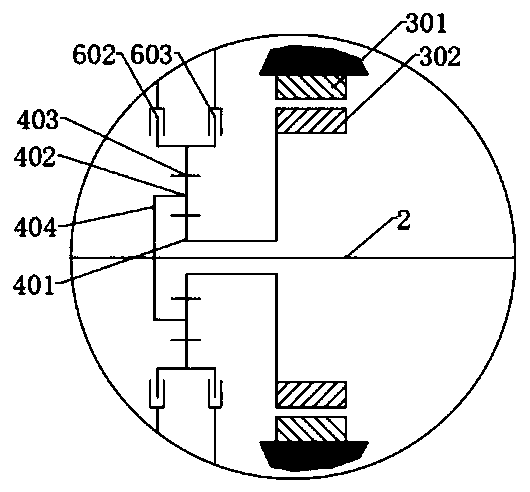

[0036] Such as Figure 1-4 As shown, the first embodiment of the present invention is an automotive planetary gear transmission device, including a split planetary gear set 4 and a compound planetary gear set 5 arranged on the same axis, the split planetary gear set 4 and the compound planetary gear set 5 A plurality of engagement elements 6 and a plurality of brake elements 7 are provided on the outer side of the diverter planetary gear set 4; the splitter planetary gear set 4 includes a splitter planetary sun gear 401, a splitter planetary ring gear 403, a splitter planet carrier 404 and a plurality of splitters A star pinion 402, the split planetary sun gear 401 is connected to the motor rotor 302, one end of the split planetary gear ring 403 meshes with the plurality of split planetary pinions 402, the split planetary gear ring 403 The other ends of the two are respectively connected to the second clutch 602 and the third clutch 603, the multiple split planetary pinions 402...

Embodiment 2

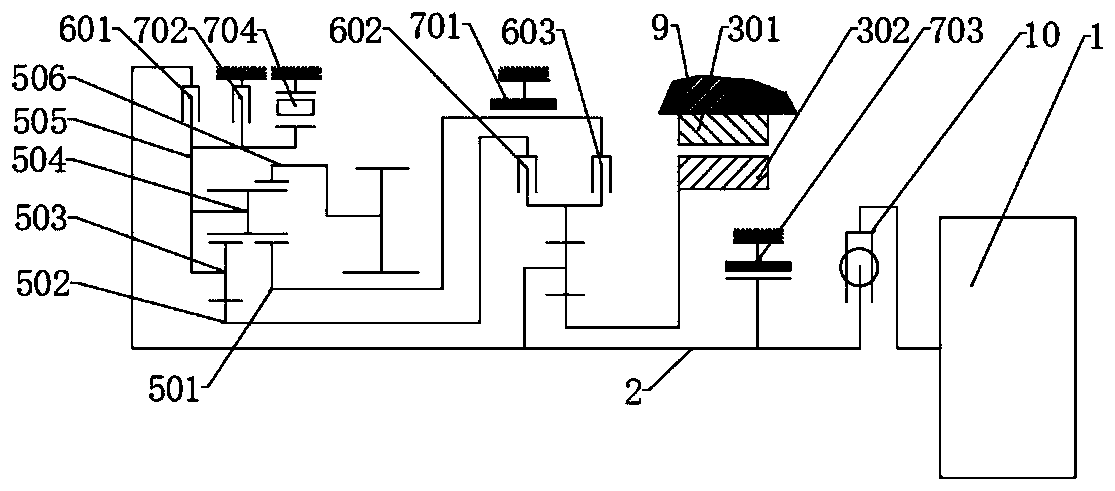

[0069] Such as Figure 5 As shown, the difference between Embodiment 2 of the present invention and Embodiment 1 is that the planetary gear transmission device is further provided with a fourth brake 705, and the fourth brake 705 is provided on the split planetary gear set 4 and the motor. 3, the active end of the fourth brake 704 is connected to the split planetary sun gear 401 and the motor rotor 302, and the passive end of the fourth brake 704 is fixed on the transmission housing 9.

[0070] Compared with embodiment 1, the braking effect of embodiment 2 of the present invention is better and more reliable. The other functions that can be implemented in the second embodiment are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com