Sodium tartrate modified copper-cobalt-iron hydrotalcite supported carbon quantum dot nanocomposite material and preparation method and application thereof

A nano-composite material and sodium tartrate technology, which is applied in the field of catalytic degradation of organic wastewater, can solve the problems of decreased cycle performance of hydrotalcite-like catalysts, less use of wet catalytic air oxidation, heavy metal pollution, etc., so as to reduce secondary pollution and accelerate Electron transfer, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

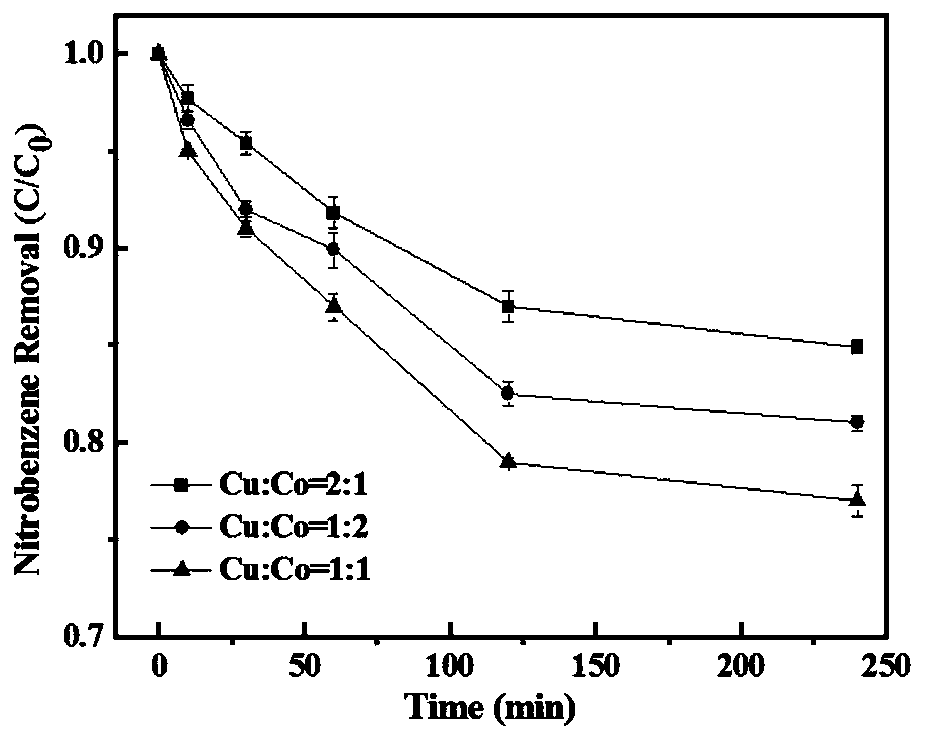

Embodiment 1

[0039] Press Cu 2+ :Co 2+ : Fe 3+ The molar ratio is 1:0.5:1 to synthesize Cu-Co-Fe-LDH. Prepare two 500mL mixed solutions respectively, marked as solution A and solution B, wherein solution A contains 24.16g Cu(NO 3 ) 2 ·3H 2 O, 29.1g Co(NO 3 ) 2 ·6H 2 O and 40.4g Fe(NO 3 ) 2 9H 2 O, solution B contains 24g NaOH and 5.3g Na 2 CO 3 , and then the prefabricated solution was slowly dripped into a flask with three necks (containing 100 mL of ultrapure water) with a peristaltic pump under vigorous stirring at 60 ° C, and passed N 2 Gas purging protection to keep the pH value of the mixed solution at 8.5±0.2. After the reaction, seal the three-necked flask, age the precipitate at 65°C for 18 hours in a constant temperature tank, then filter it, wash it repeatedly with ultrapure water until the pH value is neutral, and place the sample in an oven at 80°C Dry in medium for 12h until reaching constant weight, grind and pulverize to obtain Cu-Co-Fe-LDH.

Embodiment 2

[0041] Press Cu 2+ :Co 2+ : Fe 3+ Cu-Co-Fe-LDH was synthesized at a molar ratio of 0.5:1:1. Prepare two 500mL mixed solutions respectively, marked as solution A and solution B, wherein solution A contains 24.16g Cu(NO 3 ) 2 ·3H 2 O, 29.1g Co(NO 3 ) 2 ·6H 2 O and 40.4g Fe(NO 3 ) 2 9H 2 O, solution B contains 24g NaOH and 5.3g Na 2 CO 3 , and then the prefabricated solution was slowly dripped into a flask with three necks (containing 100 mL of ultrapure water) with a peristaltic pump under vigorous stirring at 60 ° C, and passed N 2 Gas purging protection to keep the pH value of the mixed solution at 8.5±0.2. After the reaction, seal the three-necked flask, age the precipitate at 65°C for 18 hours in a constant temperature tank, then filter it, wash it repeatedly with ultrapure water until the pH value is neutral, and place the sample in an oven at 80°C Dry in medium for 12h until reaching constant weight, grind and pulverize to obtain Cu-Co-Fe-LDH.

Embodiment 3

[0043] Press Cu 2+ :Co 2+ : Fe 3+ The molar ratio is 1:1:1 to synthesize Cu-Co-Fe-LDH. Prepare two 500mL mixed solutions respectively, marked as solution A and solution B, wherein solution A contains 24.16g Cu(NO 3 ) 2 ·3H 2 O, 29.1g Co(NO 3 ) 2 ·6H 2 O and 40.4g Fe(NO 3 ) 2 9H 2 O, solution B contains 24g NaOH and 5.3g Na 2 CO 3 , and then the prefabricated solution was slowly dripped into a flask with three necks (containing 100 mL of ultrapure water) with a peristaltic pump under vigorous stirring at 60 ° C, and passed N 2 Gas purging protection to keep the pH value of the mixed solution at 8.5±0.2. After the reaction, seal the three-necked flask, age the precipitate at 65°C for 18 hours in a constant temperature tank, then filter it, wash it repeatedly with ultrapure water until the pH value is neutral, and place the sample in an oven at 80°C Dry in medium for 12h until reaching constant weight, grind and pulverize to obtain Cu-Co-Fe-LDH.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com