Material with super-oleophobicity under water and super-hydrophobicity under oil for oil-water emulsion separation and solvent-free preparation method thereof

An underwater superoleophobic and superhydrophobic technology, which is applied in separation methods, liquid separation, grease/oily substance/floating matter removal devices, etc., can solve problems such as inability to meet application fields, harsh preparation conditions, and complex preparation processes. Achieve the effect of retaining solvent resistance, simple preparation process, and overcoming a single species

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Silica 0.15g

[0023] FeCl 3 0.81 grams

[0024] Ethanol / water 7 / 14 mL

[0025] Soaking times 4 times

[0026] Drying temperature 50℃

[0027] Pyrrole monomer 0.08 mL

[0028] Vapor deposition time 6 h

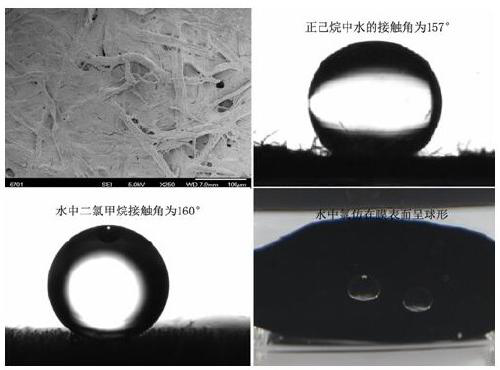

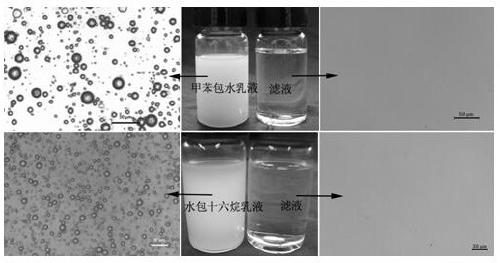

[0029] Vapor deposition temperature 35°C

[0030] Weigh each component according to the ratio described in the present invention, first disperse the nano-silica in the solvent, the over-generation time is 10min, and then under the condition of 800 r / min, FeCl 3 Add to the above mixture and stir for 10 min to form a silica dispersion containing oxidant. Then soak the filter paper with a pore size of 1-3 microns in the above solution for 30 minutes, take it out, and dry it at 50°C, repeating this process 4 times. Finally, the treated filter paper is placed in a closed container containing pyrrole monomer for gas-phase polymerization, washed with deionized water and dried. The contact angle of dichloromethane in the obtained sample water is 160°, and the contact ...

Embodiment 2

[0032] Silicon dioxide 0.20 g

[0033] FeCl 3 0.81 grams

[0034] Ethanol / water 7 / 14 mL

[0035] Soaking times 3 times

[0036] Drying temperature 50°C

[0037] Pyrrole monomer 0.10 mL

[0038] Vapor deposition time 4 h

[0039] Vapor deposition temperature 40 °C

[0040] Weigh each component according to the ratio described in the present invention, first disperse the nano-silica in the solvent, the over-generation time is 20min, and then under the condition of 1000 r / min, FeCl 3 Add to the above mixture and stir for 10 min to form a silica dispersion containing oxidant. Then soak the filter paper with a pore size of 30-50 microns in the above solution for 20 min, take it out, and dry it at 50 °C, repeating this process 3 times. Finally, the treated filter paper is placed in a closed container containing pyrrole monomer for gas-phase polymerization, washed with deionized water and dried. The underwater toluene contact angle of the obtained sample was 163°, and the con...

Embodiment 3

[0042] Silicon dioxide 0.60 g

[0043] FeCl 3 1.62 grams

[0044] Ethanol / water 30 / 60 mL

[0045] Soaking times 7 times

[0046] Drying temperature 50℃

[0047] Pyrrole monomer 0.15 mL

[0048] Vapor deposition time 6 h

[0049] Vapor deposition temperature 40°C

[0050] Weigh each component according to the ratio described in the present invention, first disperse the nano-silica in the solvent, the super-generation time is 30min, and then under the condition of 1200 r / min, FeCl 3 Add to the above mixture and stir for 10 min to form a silica dispersion containing oxidant. Then soak the filter paper with a pore size of 30-50 microns in the above solution for 20 min, take it out, and dry it at 50 °C, repeating this process 7 times. Finally, the treated filter paper is placed in a closed container containing pyrrole monomer for gas-phase polymerization, washed with deionized water and dried. The underwater toluene contact angle of the obtained filter paper fiber membran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com