Tunnel face anchor rod support design method

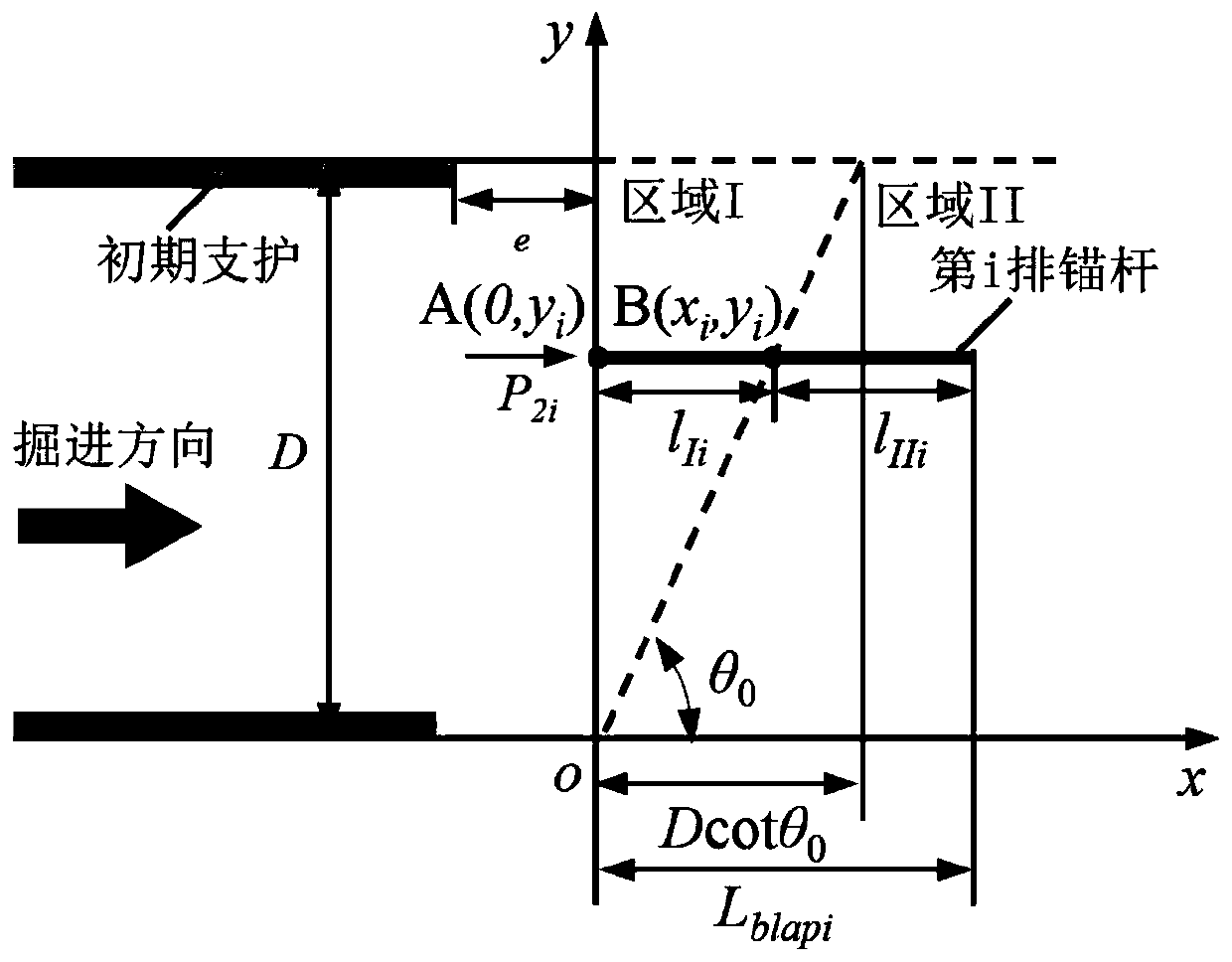

A bolt support and design method technology, applied in computer-aided design, calculation, mining equipment, etc., can solve problems such as lack of theoretical support, threat to construction safety, and large safety reserves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The large-scale mechanized full-section construction method has become the development direction of the high-speed railway tunnel construction method. Full-section excavation has few disturbances to the surrounding rock, simple procedure, and high construction efficiency, but the excavation area is large, and the tunnel face is prone to instability and collapse. Under rock conditions, the traditional step method is mainly used. Face bolt support is a commonly used advance support measure in tunnel engineering at present, but there is no relevant design specification. At present, the support parameters are mostly determined according to engineering experience, lacking theoretical support, and the GFRP bolt support on the tunnel face cannot be adjusted. Quantitative design. It may lead to large safety reserves or insufficient support parameters, threatening construction safety and causing waste of resources.

[0043] Glass fiber reinforced plastic (English: Glass-Fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com