Smoke exhaust system for common flue of building and control method thereof

A technology of public flue and smoke exhaust system, which is applied in the field of public flue of buildings, can solve the problems that the negative pressure cannot be effectively transmitted, the system exhaust resistance increases, and the balance of fan dynamics is destroyed, so as to solve the problem of poor smoke exhaust, Improves pressure distribution and ensures safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

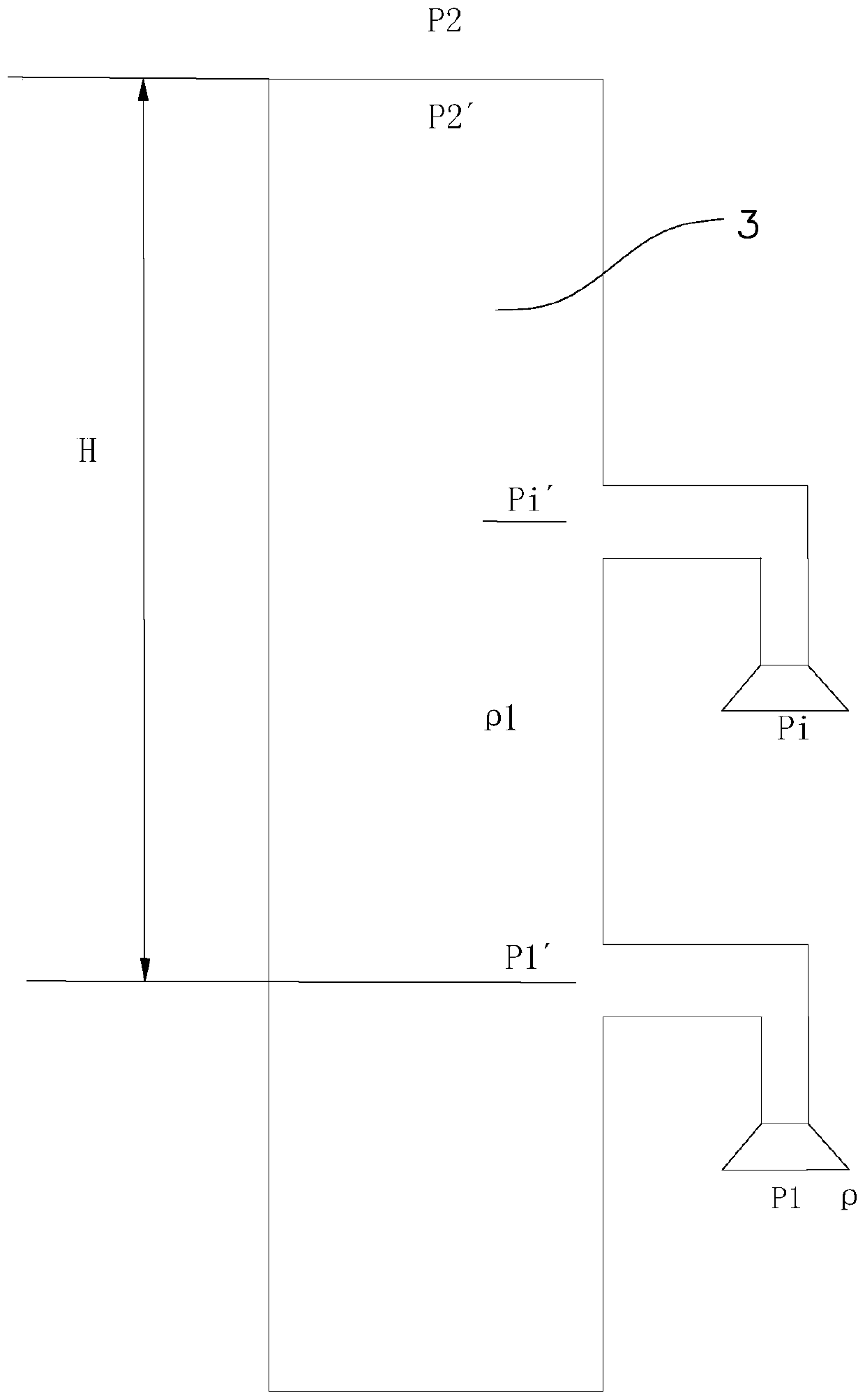

[0031] Such as figure 1 As shown, the smoke exhaust system for the public flue of the building in this embodiment includes range hoods 1 installed on different floors, and the air outlets of each range hood 1 are communicated with the public flue 3 through their respective smoke pipes 2. A fire damper 10 is installed at the outlet of the smoke pipe 2, which is prior art and will not be described in detail.

[0032] In this embodiment, an electric heating film 4 and a first temperature sensor 5 for detecting the temperature of the fume gas at the corresponding position of the flue are installed in the public flue 3 . Specifically, the electric heating film 4 is pasted on the inner wall of the public flue 3, and the electric heating film 4 and the first temperature sensor 5 are installed at the positions corresponding to each floor in the publi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com