A method for preparing large-area copper Cu(111) single crystals

A single crystal, copper foil technology, applied in the field of materials, can solve problems such as limiting the application of copper foil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

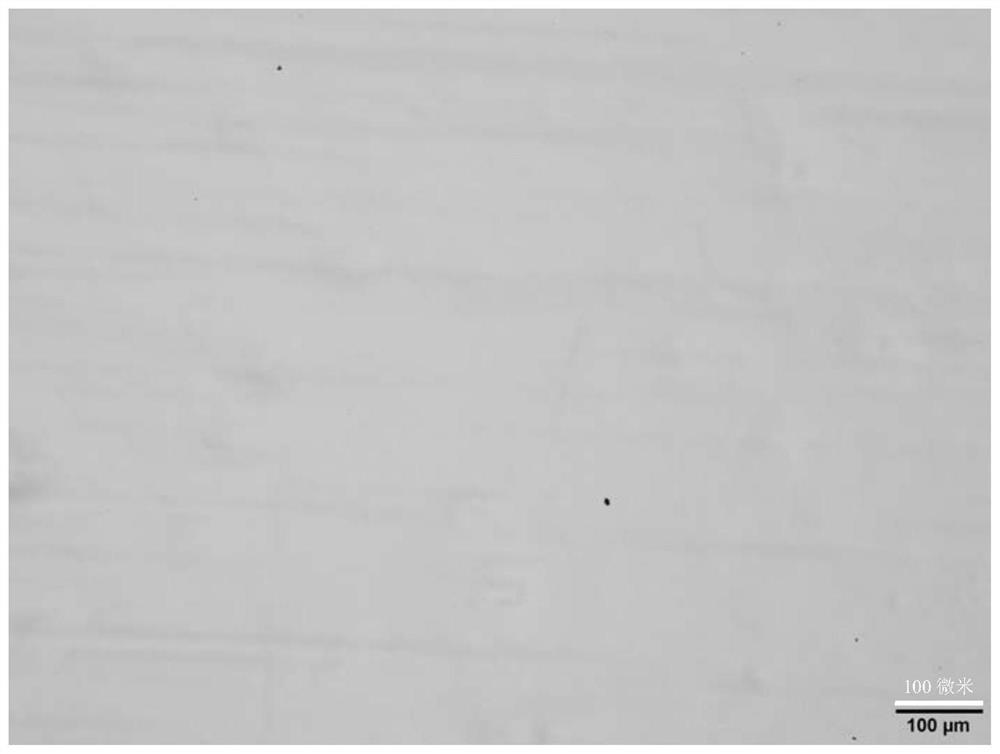

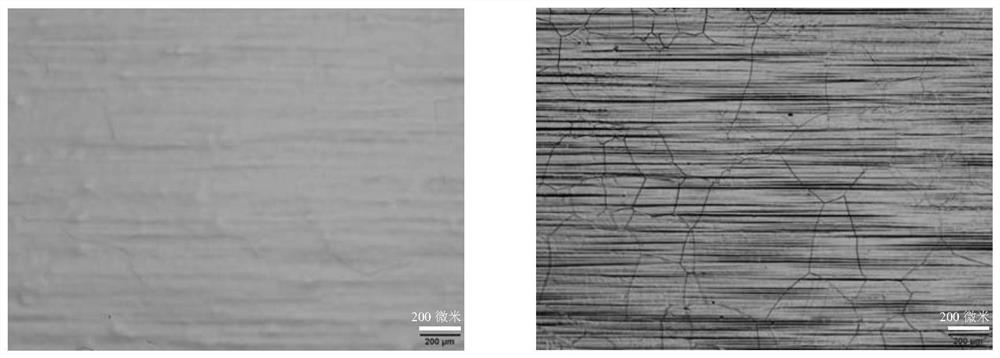

[0038] In the first step, the 100 μm thick commercial copper foil (purity 99.9%) is cut into a size of about 4cm × 6cm, and electrochemically polished in an ethanol / phosphoric acid system (wherein, the specific composition of the polishing solution is: deionized water ( mL), phosphoric acid (mL), ethanol (mL), isopropanol (mL) and urea (g) were mixed according to the ratio of 250:125:125:25:4; the condition of electrochemical polishing was: the holding voltage was 5V, the current is 2A, and the polishing time is 3min.) Wash with deionized water to remove residual polishing liquid on the surface, and blow dry with nitrogen.

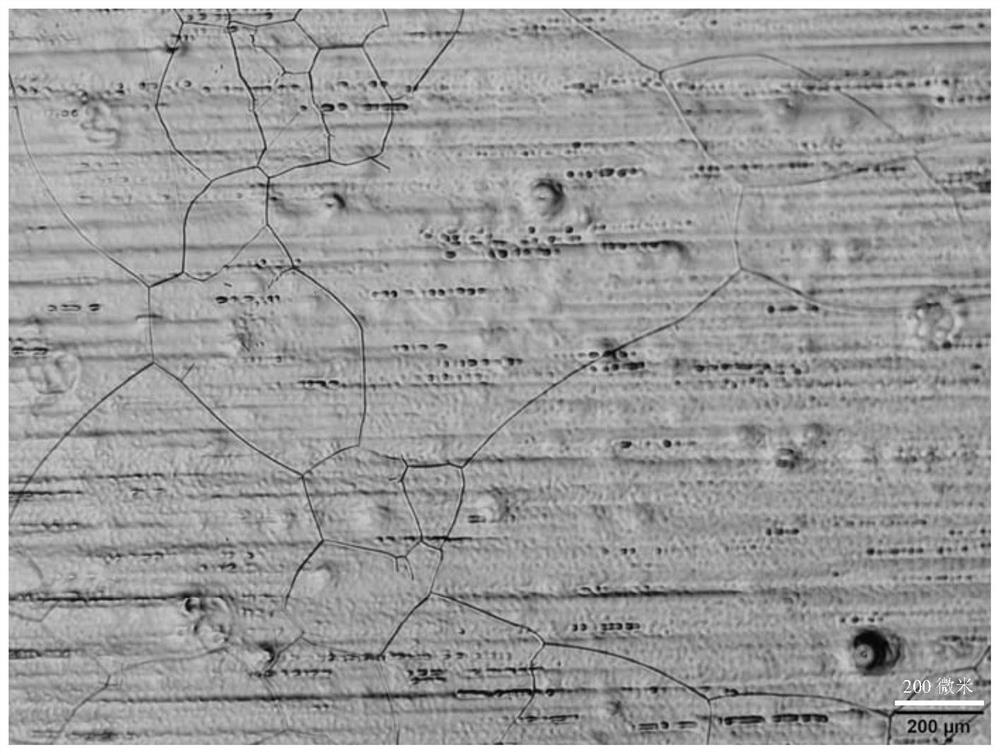

[0039] In the second step, the copper foil obtained in the first step is placed in a high-temperature tube furnace, and 200 sccm of argon gas and 100 sccm of hydrogen gas are introduced to start heating. The temperature of the tube furnace was raised to 1075°C, and the heating time was 45 minutes. Hold for 1h for annealing. After cooling down to room tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com