Civil high-strength sulfur-fixing briquette and preparation method thereof

A high-strength, civilian-use technology, applied in the field of coal product processing, can solve the problems of low coal combustion efficiency, briquette coal collapse, low thermal intensity, etc., to facilitate large-scale promotion and utilization, increase sulfur fixation rate, and improve wetting capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

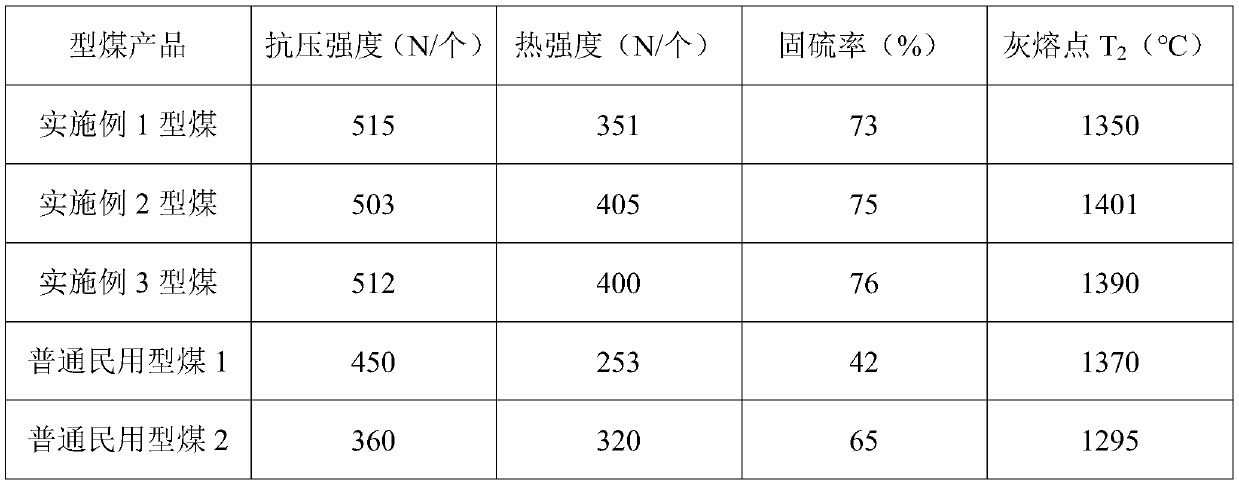

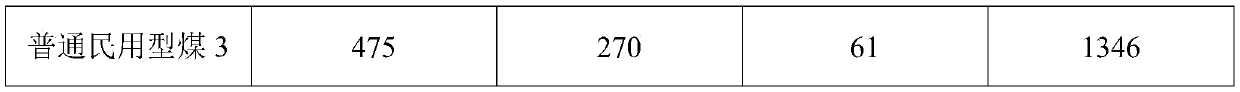

Examples

Embodiment 1

[0023] A civil high-strength sulfur-fixing briquette, the briquette is made of the following components in parts by weight: 60 parts of anthracite powder, 12 parts of fat coal powder, 1 part of sodium-based bentonite, 1 part of calcium oxide, corn preservative 0.5 parts of gelatinized starch, 0.2 parts of silicon dioxide, 0.2 parts of sodium chloride, 0.1 parts of sodium dodecylbenzenesulfonate, and 13 parts of water. Among them, the anthracite coal powder is selected from Jincheng anthracite, and the fat coal powder is selected from Shanxi Dongqu fat coal. The particle size of both anthracite and fat coal powder is less than 3mm. Sodium chloride and sodium dodecylbenzenesulfonate are solid powders.

[0024] A method for preparing civil high-strength sulfur-fixed briquettes, comprising the steps of:

[0025] (1) Anthracite and fat coal pulverized are pulverized respectively until the particle diameter of anthracite and fat coal is below 3mm;

[0026] (2) Add pulverized anthr...

Embodiment 2

[0029] A high-strength sulfur-fixing briquette for civil use, the briquette is made of the following components in parts by weight: 65 parts of anthracite powder, 13 parts of fat coal powder, 1.5 parts of sodium-based bentonite, 1.5 parts of calcium oxide, corn preservative 0.8 parts of gelatinized starch, 0.35 parts of silicon dioxide, 0.3 parts of sodium chloride, 0.15 parts of sodium dodecylbenzenesulfonate, and 14 parts of water. Among them, the anthracite coal powder is selected from Jincheng anthracite, and the fat coal powder is selected from Shanxi Dongqu fat coal. The particle size of both anthracite and fat coal powder is less than 3mm. Sodium chloride and sodium dodecylbenzenesulfonate are solid powders.

[0030] A method for preparing civil high-strength sulfur-fixed briquettes, comprising the steps of:

[0031] (1) Anthracite and fat coal pulverized are pulverized respectively until the particle diameter of anthracite and fat coal is below 3mm;

[0032] (2) Add ...

Embodiment 3

[0035] A high-strength sulfur-fixing briquette for civil use, the briquette is made of the following components in parts by weight: 70 parts of anthracite powder, 15 parts of fat coal powder, 2 parts of sodium-based bentonite, 2 parts of calcium oxide, corn preservative 1.0 parts of gelatinized starch, 0.5 parts of silicon dioxide, 0.5 parts of sodium chloride, 0.2 parts of sodium dodecylbenzenesulfonate, and 15 parts of water. Among them, the anthracite coal powder is selected from Jincheng anthracite, and the fat coal powder is selected from Shanxi Dongqu fat coal. The particle size of both anthracite and fat coal powder is less than 3mm. Sodium chloride and sodium dodecylbenzenesulfonate are solid powders.

[0036] A method for preparing civil high-strength sulfur-fixed briquettes, comprising the steps of:

[0037] (1) Anthracite and fat coal pulverized are pulverized respectively until the particle diameter of anthracite and fat coal is below 3mm;

[0038] (2) Add pulver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com