Isocyanate adhesive composition and routing fiberboard prepared from isocyanate adhesive composition

An isocyanate and adhesive technology, used in adhesives, manufacturing tools, adhesive additives, etc., can solve the problems of difficulty in forming an adhesive layer, reducing production efficiency and economic benefits, poor dimensional stability, etc., to meet the production process and appearance. Requirements, the effect of smooth milling section without burrs, excellent dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

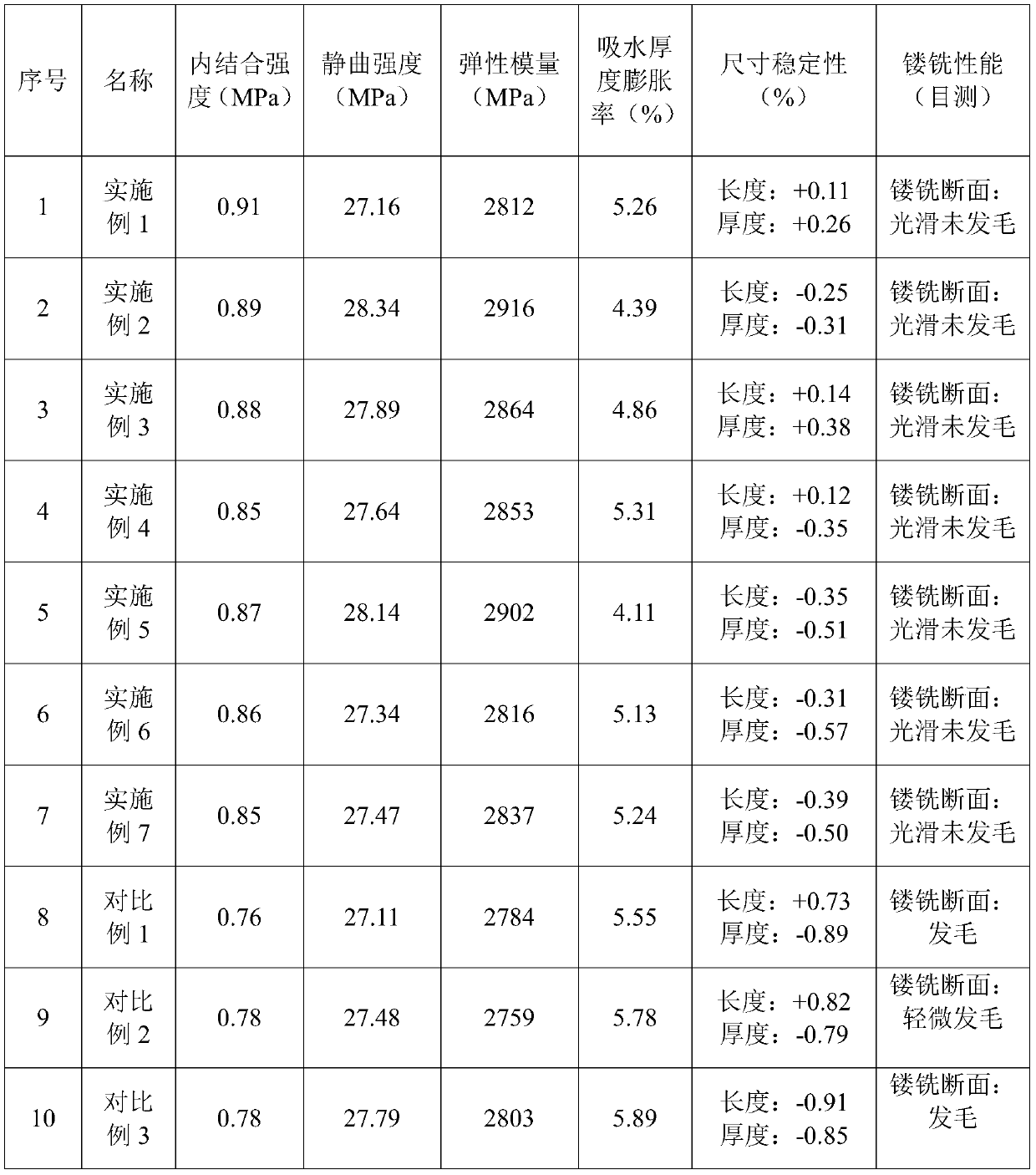

Examples

Embodiment 1

[0070] 1. Preparation of adhesive B1 component

[0071] (1) Inner crown grafting: disperse 100 kg of silica particles with 500 kg of water to obtain a suspension. This was added to 25 L of 3-(trimethoxysilylpropyl)dimethyloctadecylammonium chloride solution. The suspension was stirred and reacted at room temperature for 24 hours, and then the supernatant was discarded to obtain a crown-coated silica.

[0072] (2) Self-assembly of the outer crown: prepare a 10.5 wt% aqueous solution of tetradecyl polyoxyethylene ether potassium sulfate and adjust the pH to 10.5. Put the stirred and dispersed inner crown-coated silica in the reaction kettle, adjust to the same pH value, add 37.8 kg tetradecyl alcohol polyoxyethylene ether potassium sulfate aqueous solution, and react at 70 ° C for 24 hours to make the reaction fully proceed, then The solvent was removed, and the obtained product was washed with methanol and water respectively, and then dried at 100° C. for 48 hours, and the re...

Embodiment 2

[0090] The main preparation process of this embodiment is the same as Example 1, and has the following differences with Example 1:

[0091] 1. Preparation of adhesive B1 component

[0092] (1) Inner crown grafting: disperse 100 kg of silica particles with 500 kg of water to obtain a suspension. This was added to 25 L of 3-(trimethoxysilylpropyl)dimethyloctadecylammonium chloride solution. The suspension was stirred and reacted at room temperature for 20 hours, and then the supernatant was discarded to obtain a crown-coated silica.

[0093] (2) Self-assembly of the outer crown: prepare 10.5 wt% cetyl alcohol polyoxyethylene ether potassium sulfate aqueous solution and adjust the pH to 10. Put the stirred and dispersed inner crown-coated silica in the reaction kettle, adjust to the same pH value, add 33.6kg cetyl alcohol polyoxyethylene ether potassium sulfate aqueous solution, and react at 60°C for 20h to fully proceed the reaction, then The solvent was removed, and the obta...

Embodiment 3

[0102] The main preparation process of this embodiment is the same as Example 1, and has the following differences with Example 1:

[0103] 1. Preparation of adhesive B1 component

[0104] (1) Inner crown grafting: disperse 100 kg of silica particles with 500 kg of water to obtain a suspension. This was added to 28 L of 3-(trimethoxysilylpropyl)dimethylhexadecylammonium chloride solution. The suspension was stirred and reacted at room temperature for 20 hours, and then the supernatant was discarded to obtain a crown-coated silica.

[0105] (2) Self-assembly of the outer crown: prepare a 10.5 wt% aqueous solution of tetradecyl polyoxyethylene ether potassium sulfate and adjust the pH to 11. Put the stirred and dispersed inner crown-coated silica in the reaction kettle, adjust to the same pH value, add 37.8kg tetradecyl alcohol polyoxyethylene ether potassium sulfate aqueous solution, and react at 65°C for 20h to make the reaction fully proceed, then The solvent was removed, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com