A double-layer cement-based wave-absorbing material and its preparation method

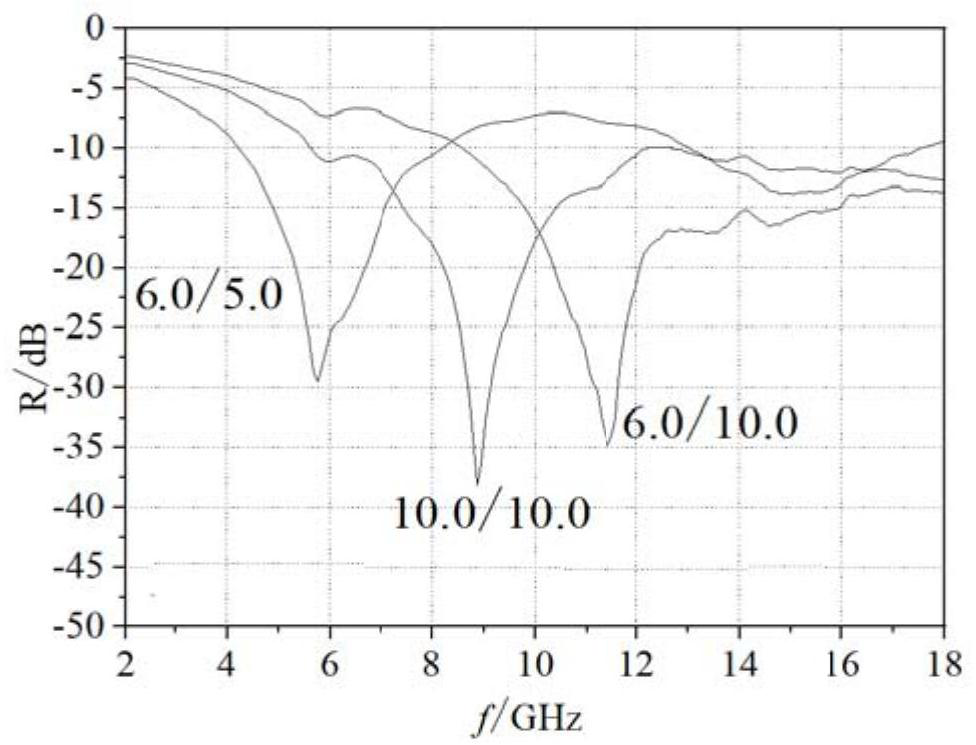

A wave-absorbing material and cement-based technology, applied in the field of functional materials, can solve the problems of narrow effective bandwidth, difficulty in satisfying the absorption broadband, and few variable parameters of the absorber, so as to achieve improved attenuation, easy spatial impedance matching, and excellent The effect of the absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method of a double-layer cement-based wave-absorbing material provided by the invention comprises the following steps:

[0035] Step 1, preparing the lower layer of absorbing material, the specific method is:

[0036] S1, in terms of parts by mass, weigh the lower wave-absorbing material, including the following raw material components: 100-130 parts of water, 10-15 parts of nano-carbonyl iron wave-absorbing material, 300-400 parts of Portland cement, 500 parts ~600 parts of fine aggregate, 800 parts of gravel and 1.0~2.0 parts of water reducer;

[0037] S2, adding the water reducer in S1 into water, stirring at room temperature until completely dissolved to obtain an aqueous solution;

[0038] S3, put the nano-carbonyl iron wave-absorbing material, Portland cement, fine aggregate and gravel in S1 into a high-speed mixer, and disperse for 30 minutes at a speed of 200r / min to obtain a powder;

[0039] S4, put the powder after high-speed mixing in S3 into ...

Embodiment 1

[0051]A preparation method of a double-layer cement-based wave-absorbing material provided by the invention comprises the following steps:

[0052] Step 1, preparing the lower layer of absorbing material, the specific method is:

[0053] S1, in terms of parts by mass, weigh the lower absorbing material, including the following raw material components: 130 parts of water, 15 parts of nano-carbonyl iron absorbing material, 400 parts of Portland cement, 500 parts of fine aggregate, 800 parts of gravel and 2.0 parts of water reducer;

[0054] S2, adding the water reducer in S1 into water, stirring at room temperature until completely dissolved to obtain an aqueous solution;

[0055] S3, put the nano-carbonyl iron wave-absorbing material, Portland cement, fine aggregate and gravel in S1 into a high-speed mixer, and disperse for 30 minutes at a speed of 200r / min to obtain a powder;

[0056] S4, put the powder after high-speed mixing in S3 into a mixer, and slowly add the aqueous s...

Embodiment 2

[0067] A preparation method of a double-layer cement-based wave-absorbing material provided by the invention comprises the following steps:

[0068] Step 1, preparing the lower layer of absorbing material, the specific method is:

[0069] S1, in terms of parts by mass, weigh the lower absorbing material, including the following raw material components: 100 parts of water, 10 parts of nano-carbonyl iron absorbing material, 300 parts of Portland cement, 600 parts of fine aggregate, 800 parts of gravel and 1.0 parts of water reducer;

[0070] S2, adding the water reducer in S1 into water, stirring at room temperature until completely dissolved to obtain an aqueous solution;

[0071] S3, put the nano-carbonyl iron wave-absorbing material, Portland cement, fine aggregate and gravel in S1 into a high-speed mixer, and disperse for 30 minutes at a speed of 200r / min to obtain a powder;

[0072] S4, put the powder after high-speed mixing in S3 into a mixer, and slowly add the aqueous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com