A laser optical path calibration method for marking equipment

A technology of optical path calibration and marking, applied in welding equipment, metal processing equipment, laser welding equipment, etc., can solve the problems of poor effect, time-consuming and laborious, no methods and steps, etc., and achieve simple calibration method and strong operability , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

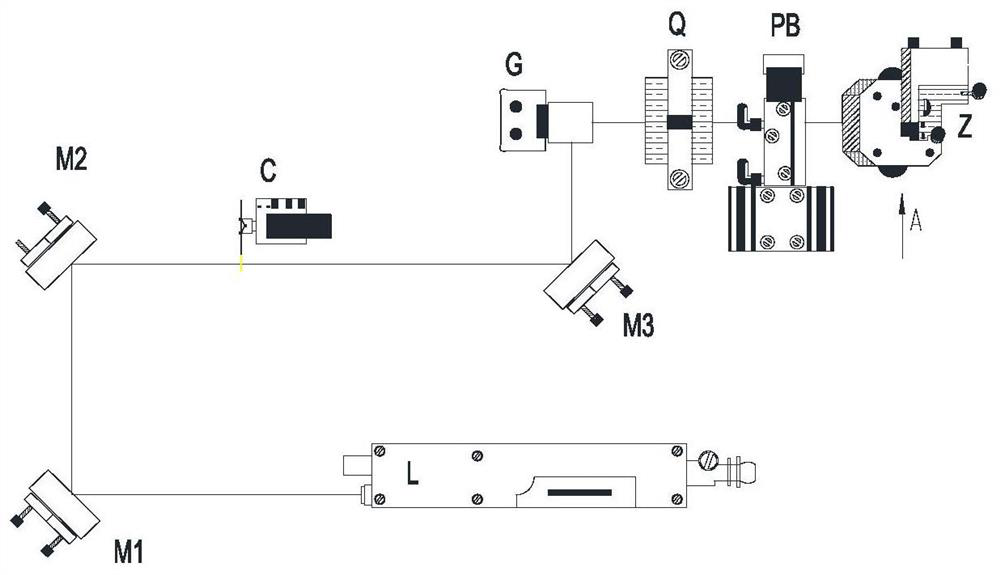

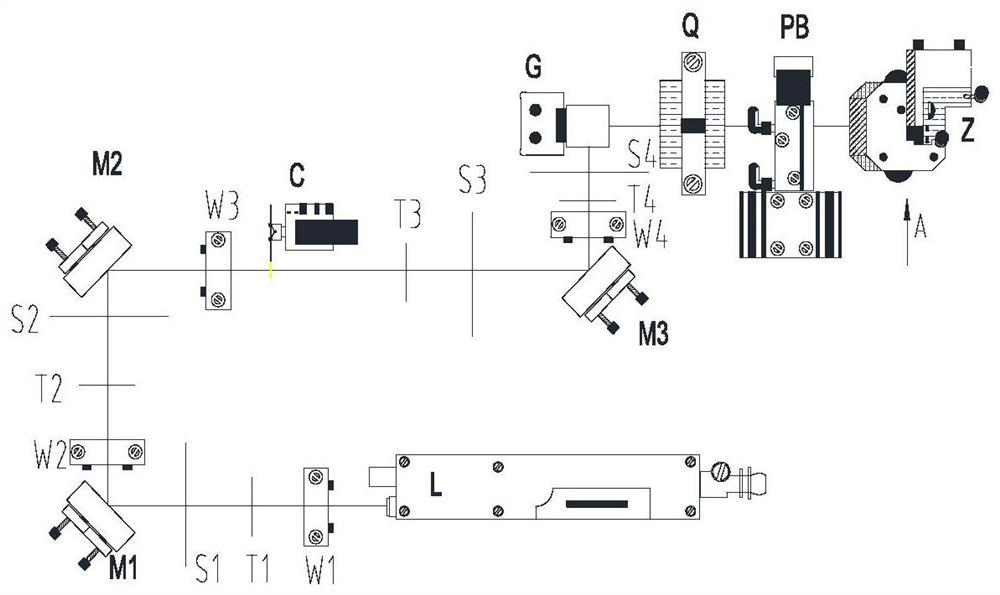

[0020] by figure 1 The marking equipment shown is an example, see figure 2 The method for calibrating the laser optical path of the marking equipment of the present invention is described, the method includes the following steps:

[0021] Step 1: Go to service mode, make sure the interlock is set and the exterior alarm light is flashing.

[0022] Step 2: Laser ignition, wear suitable laser protective glasses when igniting, the laser energy is completed at a low power (usually 330-350μs, Q switch delay).

[0023] Step 3: Move the letter mask C, the mask must be removed from the path of the laser beam.

[0024] The fourth step: rough adjustment;

[0025] Align the laser L, ignite the laser L, and check whether the emitted laser beam hits the center of the rotating mirror M1. Loosen the three nuts of the laser L, move it to the anti-vibration base, carefully adjust the angle of the laser L, adjust the rotating mirror M1 vertically, and straighten the beam so that the beam hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com